cyberbackpacker

Well-Known Member

If you have a spare, I'd be interested!

If you have a spare, I'd be interested!

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)

Would you mind sharing the spec of the pressure sensors you're using? I'm looking to use them for measuring water/wort levels.

thanks.

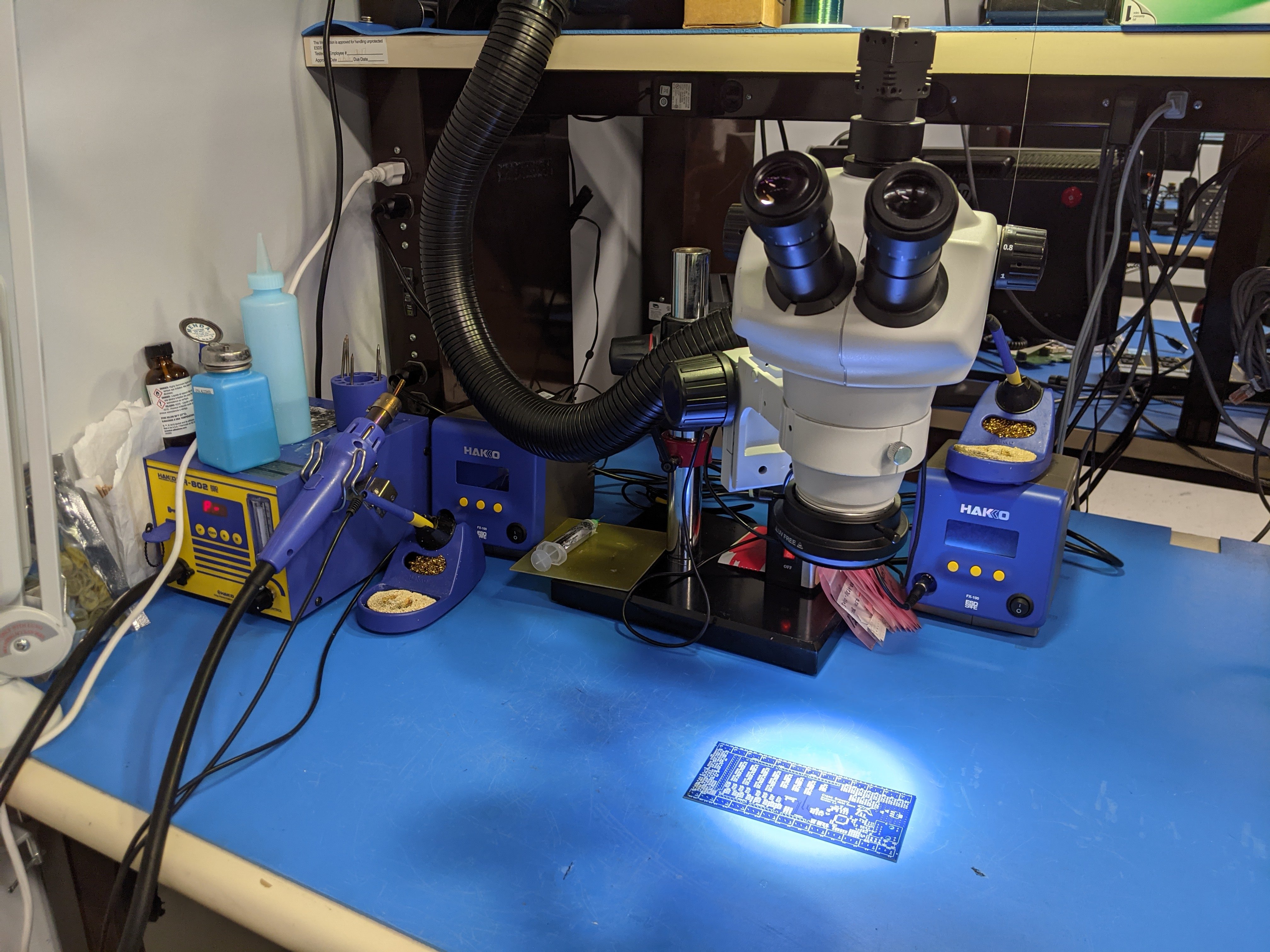

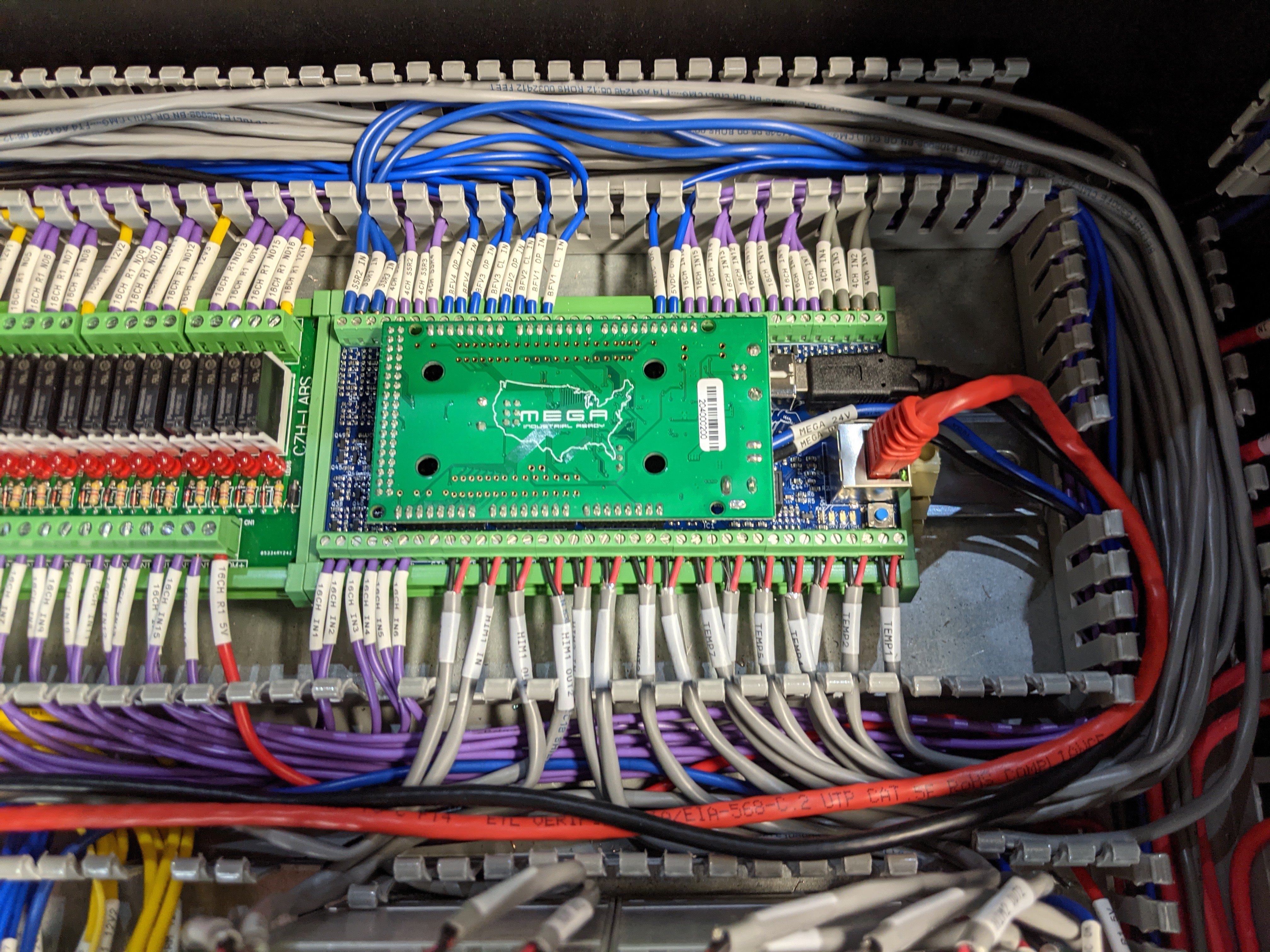

Out of curiosity, what kind of work do you do for a living? Looks amazing! Great job, and nice writeup as always.

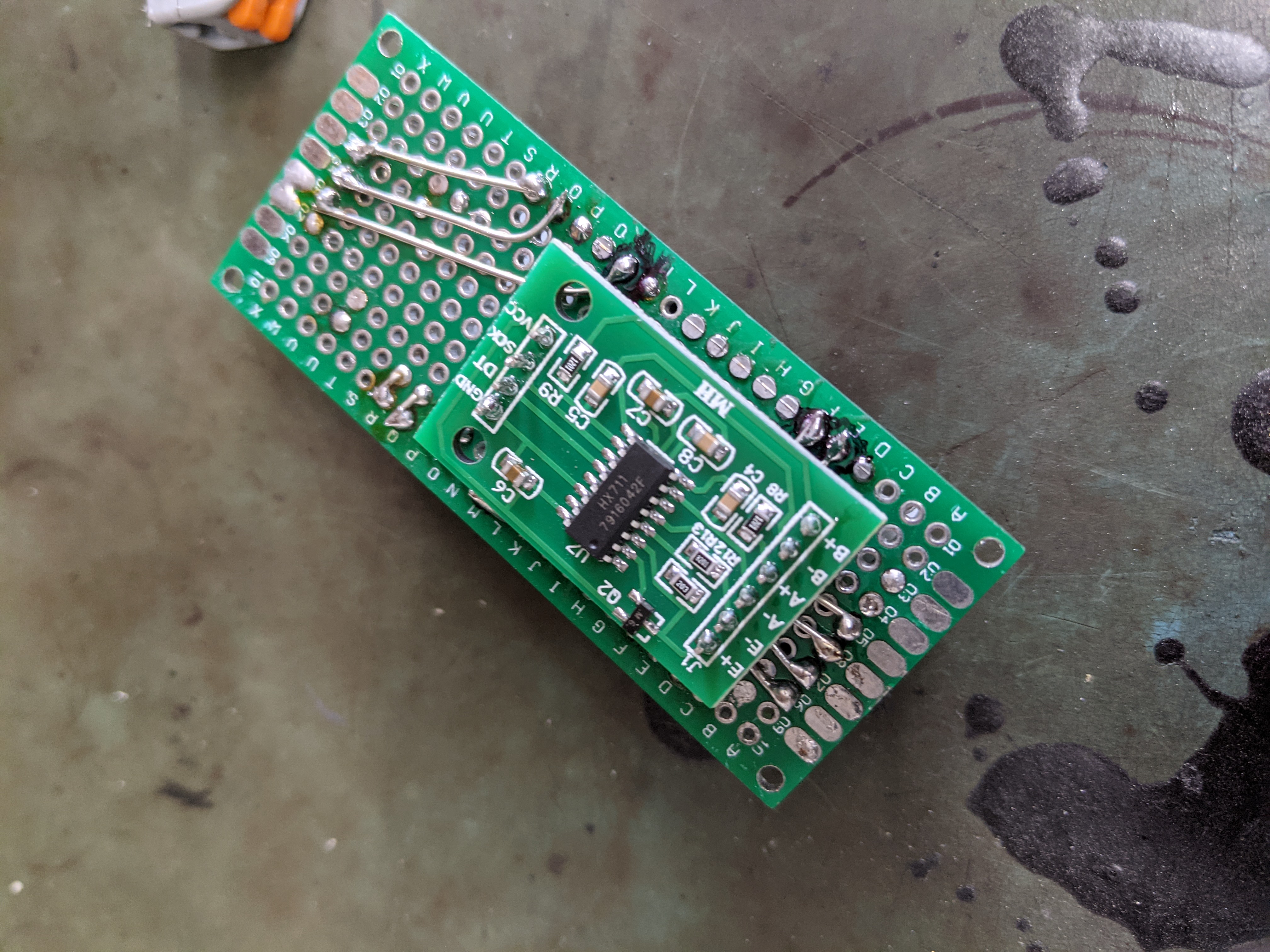

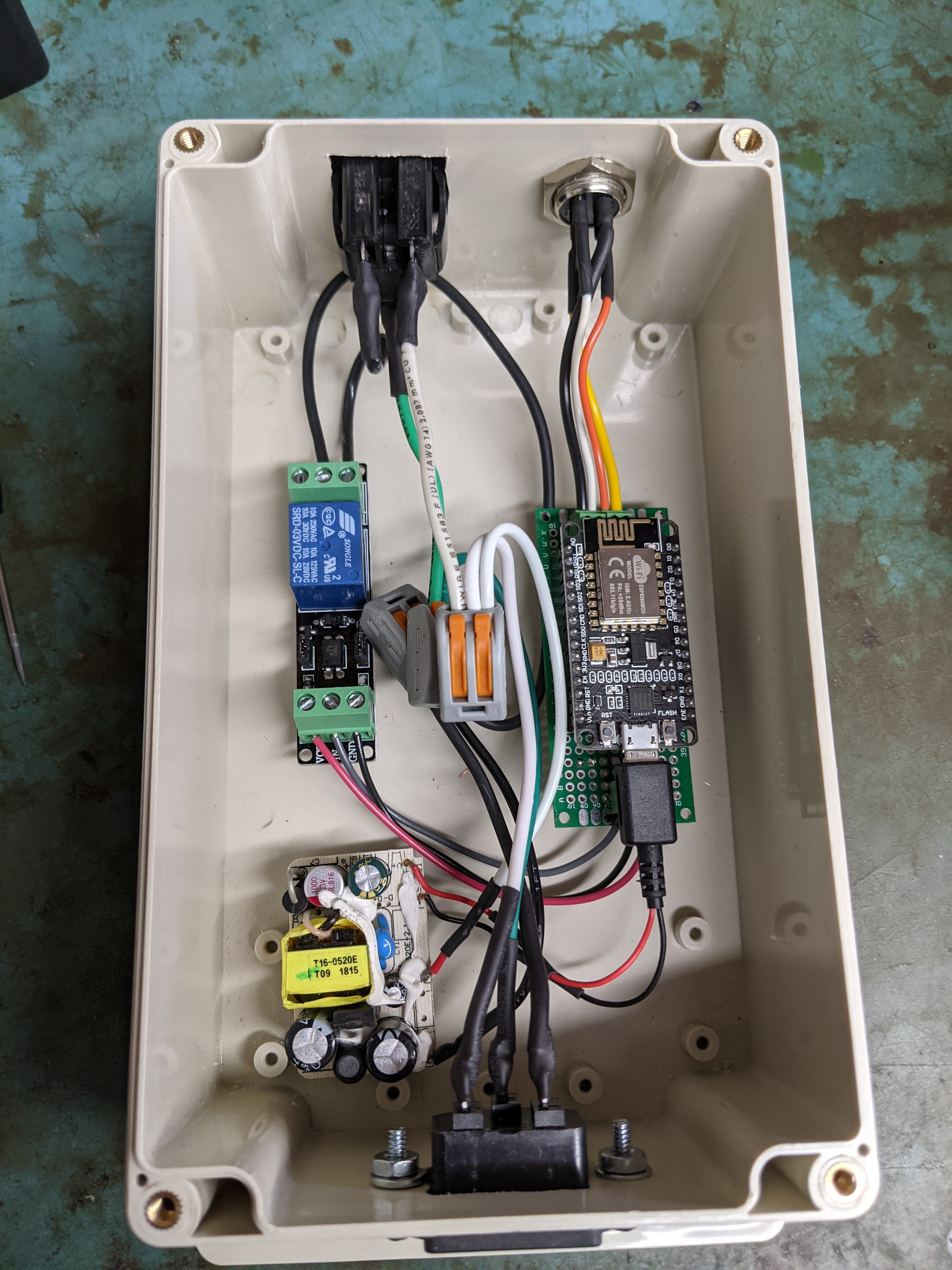

I assume you bench tested it first?!?

Wow, do you actually make beer as well?

Amazing stuff and heres me panicking about making a brewpiless or brewpi remix. I have taken a chill pill after seeing this.

Insane. I'd rather weigh one grain count and multiply to work out my grain weight than tackle your project.

Do please keep posting it's fascinating.

Yes I do have a BIAB setup that I have been brewing on while I have been working on building the automated rig.

I’d be interested in the MFM setup if there is one…

DM sentHow about the hop boss? Available?

does he have the Coriolis flow meters?DM sent

No, never got thosedoes he have the Coriolis flow meters?