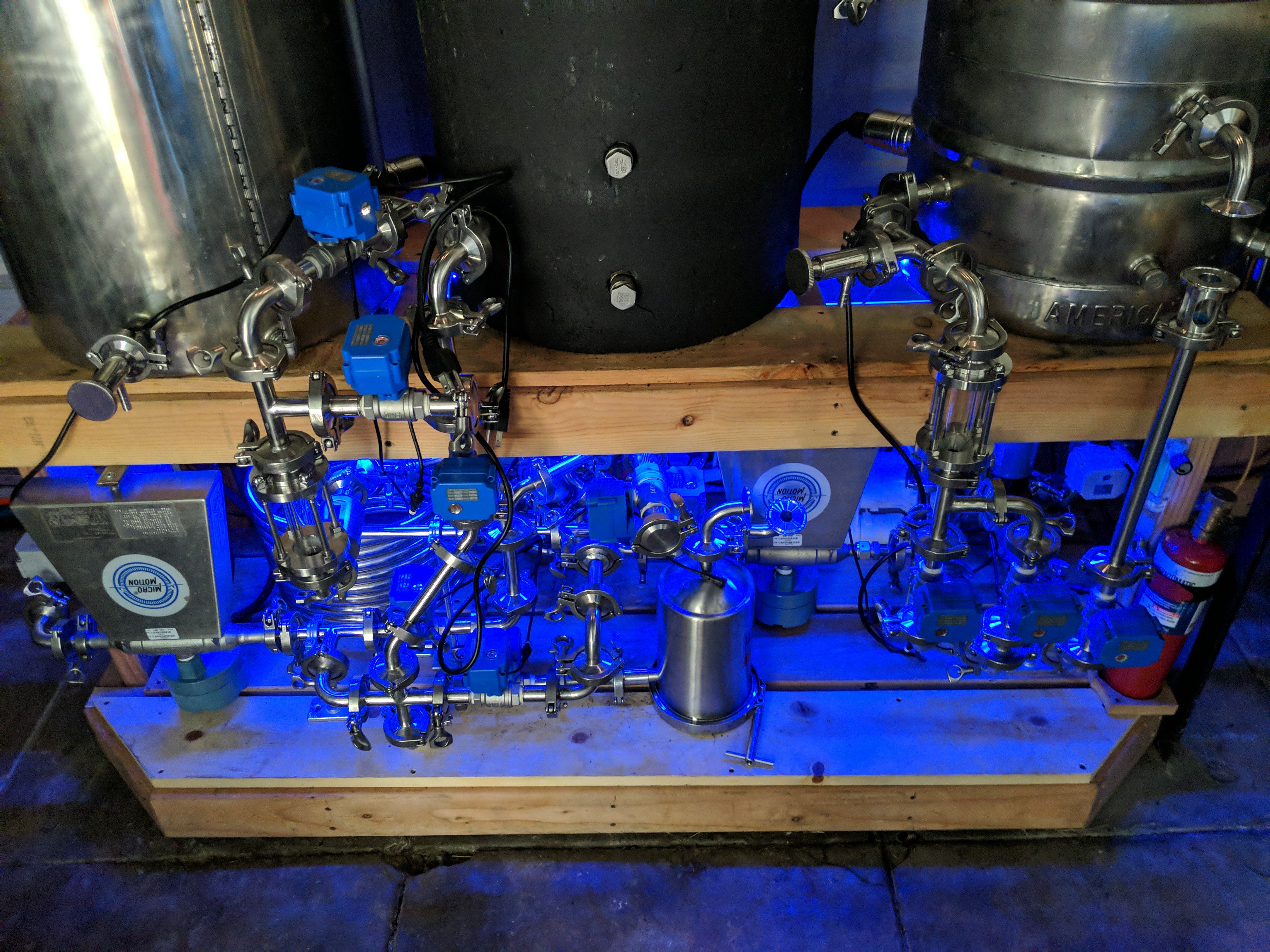

The second major revision of the plumbing is getting wrapped up. Here are the changes:

1. swapped out my paddle wheel flow meters with the IFMs.

2. added some valves to drain the MT and BK during CIP.

3. added the Hops Boss

4. added a path in the BK re-circulation loop to bypass the chiller.

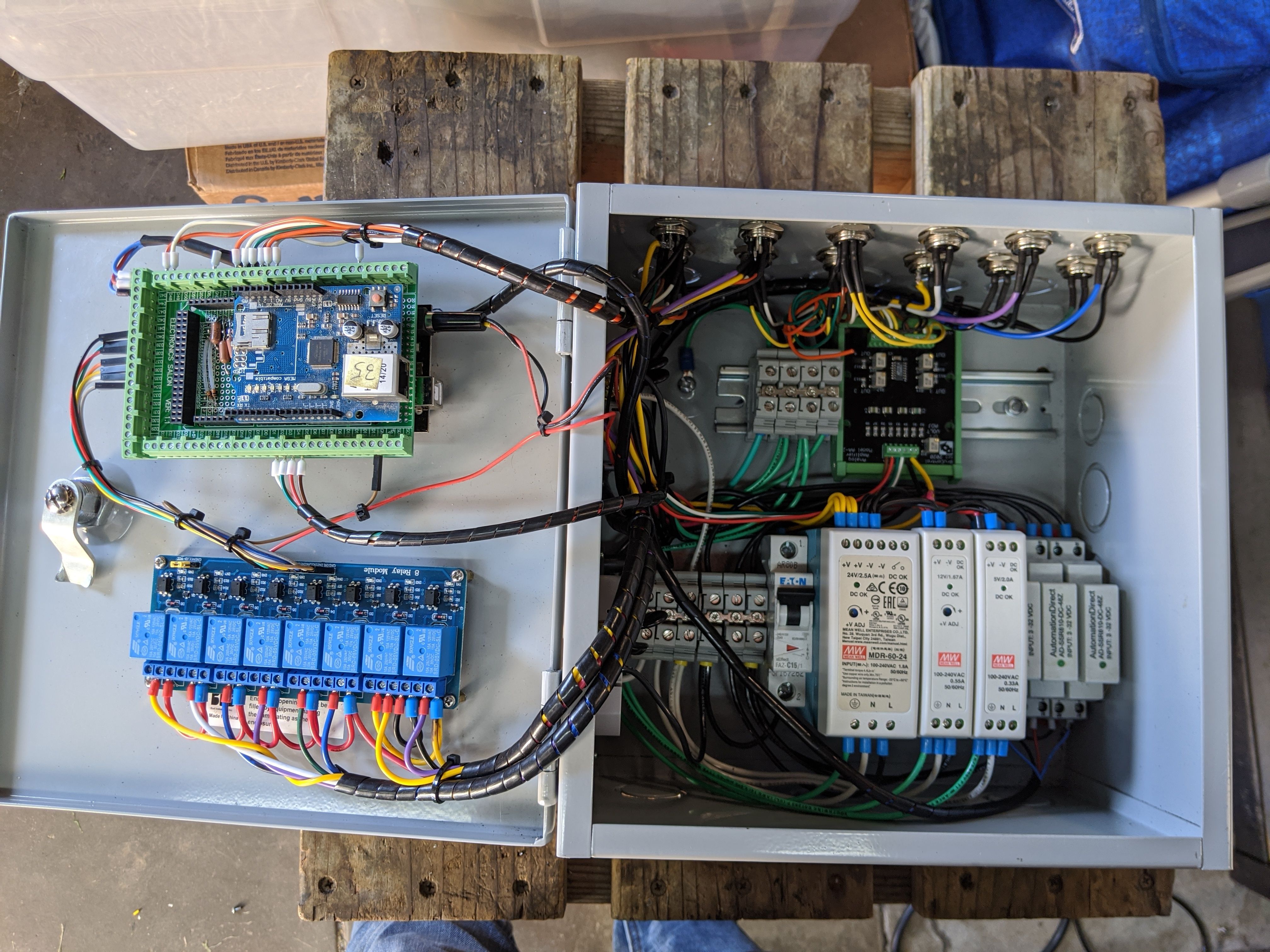

5. swapped out my DC pumps for AC pumps and added proportional valves for control flow.

I was not happy with the performance and control-ability of DC pumps. For example, when I am sparging the wort from the MT flows into the bottom of my BK, not the re-circulation return port. At the beginning of sparging the height difference between the MT and BK results in too high of a flow rate with the pump turned off. So I needed something else to restrict the flow rate.

Additionally, I found that the DC pumps had minimum duty cycle limits for the PWM outputs. However, the duty cycle necessary to get the pump spinning again is quite a bit higher. Without restricting the output of the valve, the resulting minimum flow rates were higher than I wanted.

From the testing I have done so far, these issues have been addressed with the AC pumps and proportional valves. The deadband flow control scripts I have, are working very well at quickly responding to target flow changes, as well as accurately maintaining the target flow once its there.

Finally, I thought it was inconsequential to leave a gap in the boards on the brew stand. There are over a dozen TC gaskets chilling under there now, and will stay there until I move this beast.

![Craft A Brew - Safale BE-256 Yeast - Fermentis - Belgian Ale Dry Yeast - For Belgian & Strong Ales - Ingredients for Home Brewing - Beer Making Supplies - [3 Pack]](https://m.media-amazon.com/images/I/51bcKEwQmWL._SL500_.jpg)