Unti now it was sufficient to measure very 5 seconds but maybe its good idea to have config parameter for that. The default would be 5 seconds. The temperature control depends on the selected control logic. But the good thing is that it's really easy to implement anew custom logic. In this custom logic its up to you how often you check the temperature.

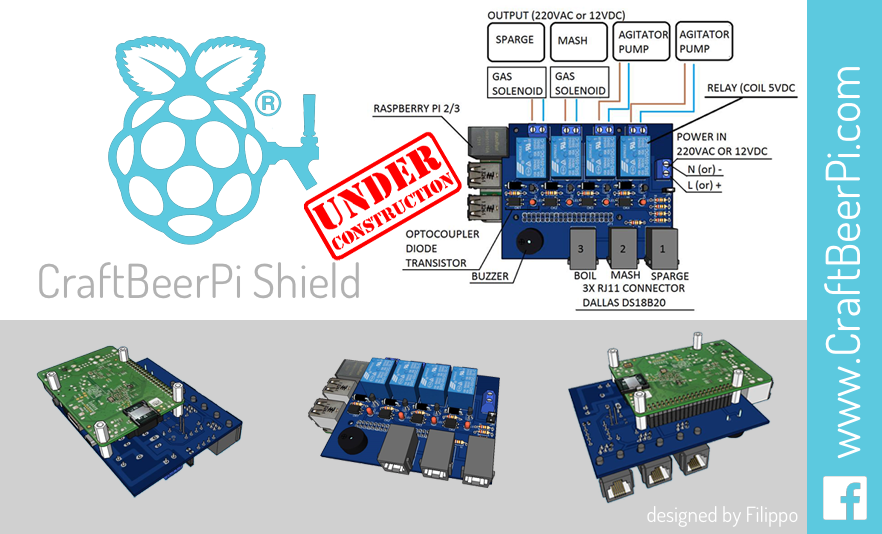

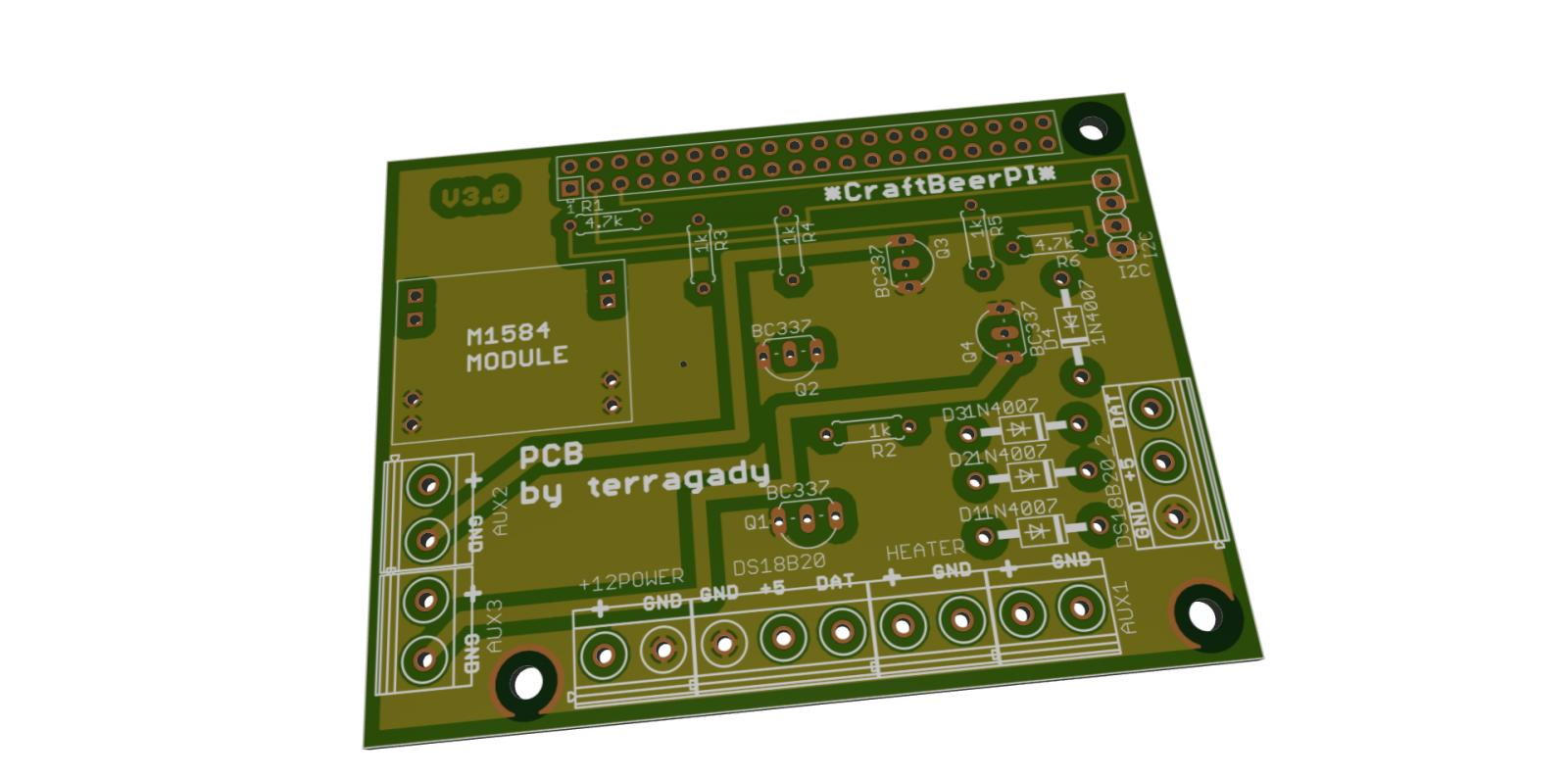

Yes, it's a good idea to place a transistor in between. Some people are asking for a custom PI shield. It would be more then welcome to get some support on this.

Yes, it's a good idea to place a transistor in between. Some people are asking for a custom PI shield. It would be more then welcome to get some support on this.

![Craft A Brew - Safale BE-256 Yeast - Fermentis - Belgian Ale Dry Yeast - For Belgian & Strong Ales - Ingredients for Home Brewing - Beer Making Supplies - [3 Pack]](https://m.media-amazon.com/images/I/51bcKEwQmWL._SL500_.jpg)