Lalo_uy

Well-Known Member

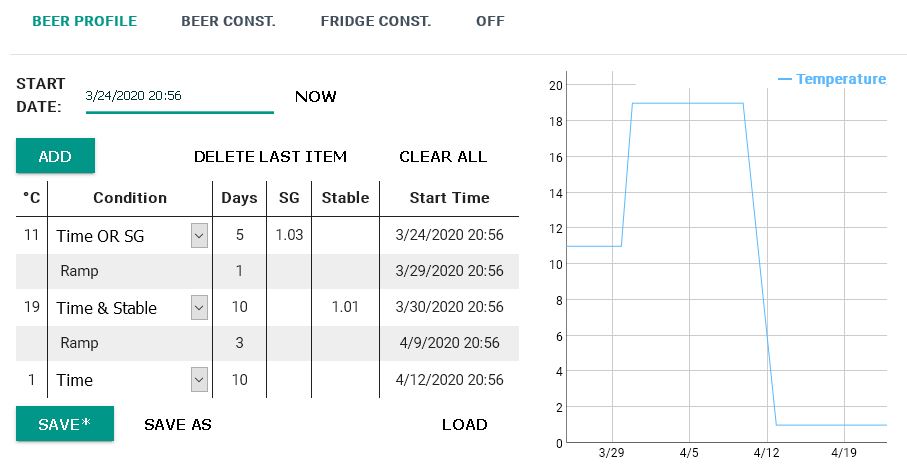

I would like to try to create a plugin for Fermentation Controller so that the target beer temperature changes with the gravity change provided by iSpindel or Tilt. I haven't done any programming in a very long time, I don't know python but I am willing to learn (steep learning curve but not much stuff to do now with the Corona thing).

Looking at the "Extended CraftBeerPi" page there are a few sections about Custom Kettle Controller and Custom Brew Step but nothing about Fermentation Controller so can somebody confirm that it's possible to create this plug-in and can you give me a hint or two where to start?

More than a Fermentation Controller, you need a Fermentation Step, that instead of looking for the temp, go looking for the gravity.

But the Fermentation Steps are into the fermenter module, and there is no prevision for having different ones, as in Brewing.

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)