Agreed with the above suggestion to go PID/SSR from day one. The bonus feature is that you could use it as a temp controller at any point just by adding the thermocouple. Freddy's PWM + SSR is a neat geeky project for sure but at least with the PID, you get a fancy digital display out of the deal.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Controllerless electric boil keggle

- Thread starter conpewter

- Start date

Help Support Homebrew Talk:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

freddyb

Well-Known Member

- Joined

- Apr 1, 2008

- Messages

- 179

- Reaction score

- 7

Interesting; would a 12V DC power supply be needed to run this?

Yep. I already have a 12V wall wort in my control box so it works out well for me

GreenMonti

Well-Known Member

- Joined

- Nov 29, 2009

- Messages

- 1,268

- Reaction score

- 67

Nevermind.....

Did I manage to offend you in some way? Or is my lack of knowledge not worth your time?

whitescout

Well-Known Member

I have read countless posts on the best way to control electric elements. I looked into PWMs, and infinite control switches, etc... I believe that the most simple, cost effective way to control an element is with a PID, and SSR.

GreenMonti, I have read your posts concerning welding, and I believe that you are not lazy, and I think that you are wrong about the PID and SSR being too complicated.

If you think about the SSR being a contactor, and the PID being a switch to close the contactor, this probably the easiest way to think about it.

A bonus with the PID, is that you can manually control the output, or you can let the PID maintain output.

Just my .02

GreenMonti, I have read your posts concerning welding, and I believe that you are not lazy, and I think that you are wrong about the PID and SSR being too complicated.

If you think about the SSR being a contactor, and the PID being a switch to close the contactor, this probably the easiest way to think about it.

A bonus with the PID, is that you can manually control the output, or you can let the PID maintain output.

Just my .02

The Pol

Well-Known Member

- Joined

- Feb 12, 2007

- Messages

- 11,390

- Reaction score

- 120

Did I manage to offend you in some way? Or is my lack of knowledge not worth your time?

Ha ha no no... I wrote something else, I and I answered my own question.

Wade E

Beer Buster

The Ranco Controller and probably the Johnson are also 240v. but you might need a relay if you go over the amp range given.

$20.94

$29.99

The Brew Your Own Big Book of Clone Recipes: Featuring 300 Homebrew Recipes from Your Favorite Breweries

Amazon.com

$33.99 ($17.00 / Count)

$41.99 ($21.00 / Count)

2 Pack 1 Gallon Large Fermentation Jars with 3 Airlocks and 2 SCREW Lids(100% Airtight Heavy Duty Lid w Silicone) - Wide Mouth Glass Jars w Scale Mark - Pickle Jars for Sauerkraut, Sourdough Starter

Qianfenie Direct

$7.79 ($7.79 / Count)

Craft A Brew - LalBrew Voss™ - Kveik Ale Yeast - For Craft Lagers - Ingredients for Home Brewing - Beer Making Supplies - (1 Pack)

Craft a Brew

$39.22 ($39.22 / Count)

Brewer's Best Home Brew Beer Ingredient Kit - 5 Gallon (Mexican Cerveza)

Amazon.com

$53.24

1pc Hose Barb/MFL 1.5" Tri Clamp to Ball Lock Post Liquid Gas Homebrew Kegging Fermentation Parts Brewer Hardware SUS304(Gas MFL)

Guangshui Weilu You Trading Co., Ltd

$10.99 ($31.16 / Ounce)

Hornindal Kveik Yeast for Homebrewing - Mead, Cider, Wine, Beer - 10g Packet - Saccharomyces Cerevisiae - Sold by Shadowhive.com

Shadowhive

$53.24

1pc Hose Barb/MFL 1.5" Tri Clamp to Ball Lock Post Liquid Gas Homebrew Kegging Fermentation Parts Brewer Hardware SUS304(Gas MFL)

yunchengshiyanhuqucuichendianzishangwuyouxiangongsi

$176.97

1pc Commercial Keg Manifold 2" Tri Clamp,Ball Lock Tapping Head,Pressure Gauge/Adjustable PRV for Kegging,Fermentation Control

hanhanbaihuoxiaoshoudian

$22.00 ($623.23 / Ounce)

AMZLMPKNTW Ball Lock Sample Faucet 30cm Reinforced Silicone Hose Secondary Fermentation Homebrew Kegging joyful

无为中南商贸有限公司

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)

$6.95 ($17.38 / Ounce)

$7.47 ($18.68 / Ounce)

Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]

Hobby Homebrew

$479.00

$559.00

EdgeStar KC1000SS Craft Brew Kegerator for 1/6 Barrel and Cornelius Kegs

Amazon.com

$58.16

HUIZHUGS Brewing Equipment Keg Ball Lock Faucet 30cm Reinforced Silicone Hose Secondary Fermentation Homebrew Kegging Brewing Equipment

xiangshuizhenzhanglingfengshop

chefchris

Well-Known Member

i'm in the process of going all electric but know nothing about electricity. let me know if anyone wants to build me a PID - SSR thingy. I would gladly pay for it. The only thing that I'm waiting on is which elements to buy. I can't decide which size to get for my keggles and controling the output would be the solution.

You could get a single 5500W element and drive it with 240VAC until the boil starts. Then, use a SPDT switch to disconnect one leg of the 240VAC source and connect a neutral line in its place. You would then have 120VAC driving the element at 1375W.

I don't know if you could sustain a 15-20 gallon boil at 1375W, but a 5-10 gallon brew should be ok. I'm using 2750W to sustain a 17.5 gallon rolling boil on my rig.

I don't know if you could sustain a 15-20 gallon boil at 1375W, but a 5-10 gallon brew should be ok. I'm using 2750W to sustain a 17.5 gallon rolling boil on my rig.

chefchris

Well-Known Member

You could get a single 5500W element and drive it with 240VAC until the boil starts. Then, use a SPDT switch to disconnect one leg of the 240VAC source and connect a neutral line in its place. You would then have 120VAC driving the element at 1375W.

I don't know if you could sustain a 15-20 gallon boil at 1375W, but a 5-10 gallon brew should be ok. I'm using 2750W to sustain a 17.5 gallon rolling boil on my rig.

very interested in this. I will be doing 5-10 gallon batches.

can I pick one of these switches up at the hardware store? any kind of write up or tutorial showing this? sounds fairly easy.

GreenMonti

Well-Known Member

- Joined

- Nov 29, 2009

- Messages

- 1,268

- Reaction score

- 67

Ha ha no no... I wrote something else, I and I answered my own question.

What was the question Pol?

GreenMonti

Well-Known Member

- Joined

- Nov 29, 2009

- Messages

- 1,268

- Reaction score

- 67

I have read countless posts on the best way to control electric elements. I looked into PWMs, and infinite control switches, etc... I believe that the most simple, cost effective way to control an element is with a PID, and SSR.

GreenMonti, I have read your posts concerning welding, and I believe that you are not lazy, and I think that you are wrong about the PID and SSR being too complicated.

If you think about the SSR being a contactor, and the PID being a switch to close the contactor, this probably the easiest way to think about it.

A bonus with the PID, is that you can manually control the output, or you can let the PID maintain output.

Just my .02

For those seeking a automated or a semi automated system, a PID is essential.

Me, I want to be there and in it. I love mechanical things. I also love old school stuff. It always seems to be the stuff that just keeps going. There isn't a digital display to go funky or more connections to give grief due to corrosion. How about a bad crimp on the wires? Less is more in my eyes.

While I may be wrong about a PID and a SSR being complicated....I think that is because you understand it. I don't. I also don't see why you would want 2 devices to do the same thing that 1 device can do? This adds complexity to the system, and adds time to trouble shooting should something go crazy. Doesn't a PID require a temp sensor? How else would it know when to tell the SSR to fire? Yet another thing in the mix. When it comes to a simple boil kettle, a simple knob is all that is required.

I do think of a SSR as bieing a contactor because that's all it is. I understand relays. I have used them for a great number of things automotive. I used to install car alarms and all the other goodies.

I thank you for saying that I am not lazy. That is very kind of you to say. Prost Friend.

McCuckerson

Well-Known Member

Could you do the same type of thing by putting the previously mentioned infinite switch onto 1 leg of the 5500W element. Then at full bore you would have 5500W and it would be adjustable from 2750W to 5500W for post boil control? Or would that mess with the GCFI?You could get a single 5500W element and drive it with 240VAC until the boil starts. Then, use a SPDT switch to disconnect one leg of the 240VAC source and connect a neutral line in its place. You would then have 120VAC driving the element at 1375W.

I don't know if you could sustain a 15-20 gallon boil at 1375W, but a 5-10 gallon brew should be ok. I'm using 2750W to sustain a 17.5 gallon rolling boil on my rig.

The Pol

Well-Known Member

- Joined

- Feb 12, 2007

- Messages

- 11,390

- Reaction score

- 120

Could you do the same type of thing by putting the previously mentioned infinite switch onto 1 leg of the 5500W element. Then at full bore you would have 5500W and it would be adjustable from 2750W to 5500W for post boil control? Or would that mess with the GCFI?

I would think that would mess with the GFCI trying to read the return current.

Interesting; would a 12V DC power supply be needed to run this?

would this power supply work?

http://www.dealextreme.com/p/ac-to-dc-12v-1a-power-adaptor-with-5-4mm-dc-plug-us-type-110-240v-15989

If you're interested I can post instructions.

Mine has a welded bung to thread the element into, but you could use weldless fittings to secure the element. I had it that way until I broke down and finally welded the bung in.

Mine has a welded bung to thread the element into, but you could use weldless fittings to secure the element. I had it that way until I broke down and finally welded the bung in.

beeton

Well-Known Member

I'd like to read your how-to.

Dave.

Dave.

conpewter

Well-Known Member

If you're interested I can post instructions.

Mine has a welded bung to thread the element into, but you could use weldless fittings to secure the element. I had it that way until I broke down and finally welded the bung in.

I'd really like to know where you got the 20amp infinite switch 240V. Still looking for a 25A one to handle a 5500W element... but could get by fine with a 4500W element.

pvtschultz

Well-Known Member

You could go with a pair of heating elements with one or both being controlled by an infinite switch. I looked around the net for a bit and couldn't come up with much above 15 amps. Two 15A switches might be more cost effective than a single 25 or 30 Amp version.

EarthBound

Well-Known Member

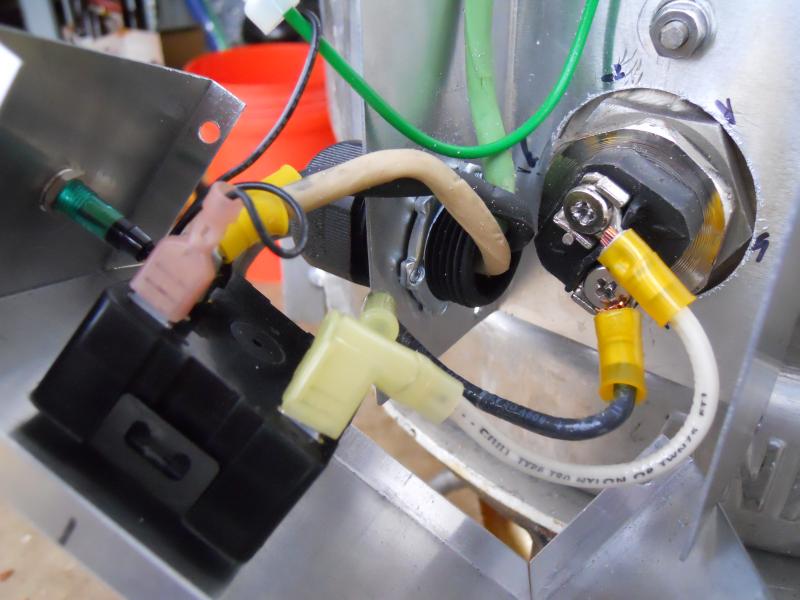

Here is my controller-less E-Keggle

20 amp infinite control with 4500 watt element

Please excuse the crud on my keggle.

Nice work, man! I'd like to see a write-up, too.

Actually, I think the switch is rated for 15 amps. My bad.

I could have sworn it was 20 amps but I have been known to be wrong. The specs on the switch are no longer legible.

I'm drawing 18 amps from my element.

Yeah, I'm pushing it, but I've brewed over a dozen times with this setup and no problems as of yet.

I can get 10 gallons boiling in about 50 to 60 minutes

7 1/2 gallons in 40 minutes

I could have sworn it was 20 amps but I have been known to be wrong. The specs on the switch are no longer legible.

I'm drawing 18 amps from my element.

Yeah, I'm pushing it, but I've brewed over a dozen times with this setup and no problems as of yet.

I can get 10 gallons boiling in about 50 to 60 minutes

7 1/2 gallons in 40 minutes

ScubaSteve

Well-Known Member

- Joined

- May 21, 2007

- Messages

- 3,673

- Reaction score

- 91

Is that 18 amps from your element at max, or just in general? Not sure exactly how the infinite switch works, but if it's like a PWM, you could probably stick a cheap 40A SSR in that box with room to spare....and your overcurrent worries are over!

How does it do with being stuck to the side of a 200F keg?

How does it do with being stuck to the side of a 200F keg?

conpewter

Well-Known Member

I'd gladly use a infinite switch and SSR, but I don't think it would work since most SSRs take a DC input to turn on and off, and even the ones that take AC would not be able to take enough amperage to let the infinite switch work.

The switch works by heating up a bimetal strip that will disconnect the two sources as it gets too hot, then re-connect as it cools. If I remember right.

The switch works by heating up a bimetal strip that will disconnect the two sources as it gets too hot, then re-connect as it cools. If I remember right.

The 240v 15A infinite switch seems perfect as a cheap alternative. You can use a 3500W element and should be able maintain a boil on 12 gallons. I think I might actually like this better than a PID and SSR. It seems to give better control of the boil off rate. I might just be a little unsure how a PID is used to control the boil off rate. It seems a PID used for the BK is just trying to maintain 212F. Maybe someone with a better understanding could clear up the use of a PID on a BK.

Thanks for the idea on the infinite switch though!

Thanks for the idea on the infinite switch though!

conpewter

Well-Known Member

If you get the right PID it will work in temp control mode and manual mode. Manual mode will let you set the percentage that the element is on. I normally run around 55-60% during the boil with a 5500 Watt element and a 7 gal boil.

Just wish there was an infinite switch that could control the 5500W element, would be simpler on the boil kettle.

Just wish there was an infinite switch that could control the 5500W element, would be simpler on the boil kettle.

Check this out

http://www.robertshawtstats.com/spaw2/SiteContent/Files/FAQ/150-2160.pdf

this should clear things up for anyone interested

I also have a PDF of an electric kettle build using the infinite burner switch

http://www.robertshawtstats.com/spaw2/SiteContent/Files/FAQ/150-2160.pdf

this should clear things up for anyone interested

I also have a PDF of an electric kettle build using the infinite burner switch

conpewter

Well-Known Member

Check this out

http://www.robertshawtstats.com/spaw2/SiteContent/Files/FAQ/150-2160.pdf

this should clear things up for anyone interested

Cool, so yes a 15amp control. Do you have a GFCI on this circuit?

Similar threads

- Replies

- 8

- Views

- 646

- Replies

- 10

- Views

- 3K

- Replies

- 11

- Views

- 977

Latest posts

-

-

Pilsner Malt Comparison: Rahr vs. Weyermann vs. Great Western vs. Viking

- Latest: FranklinsBeerTower

-

-

-