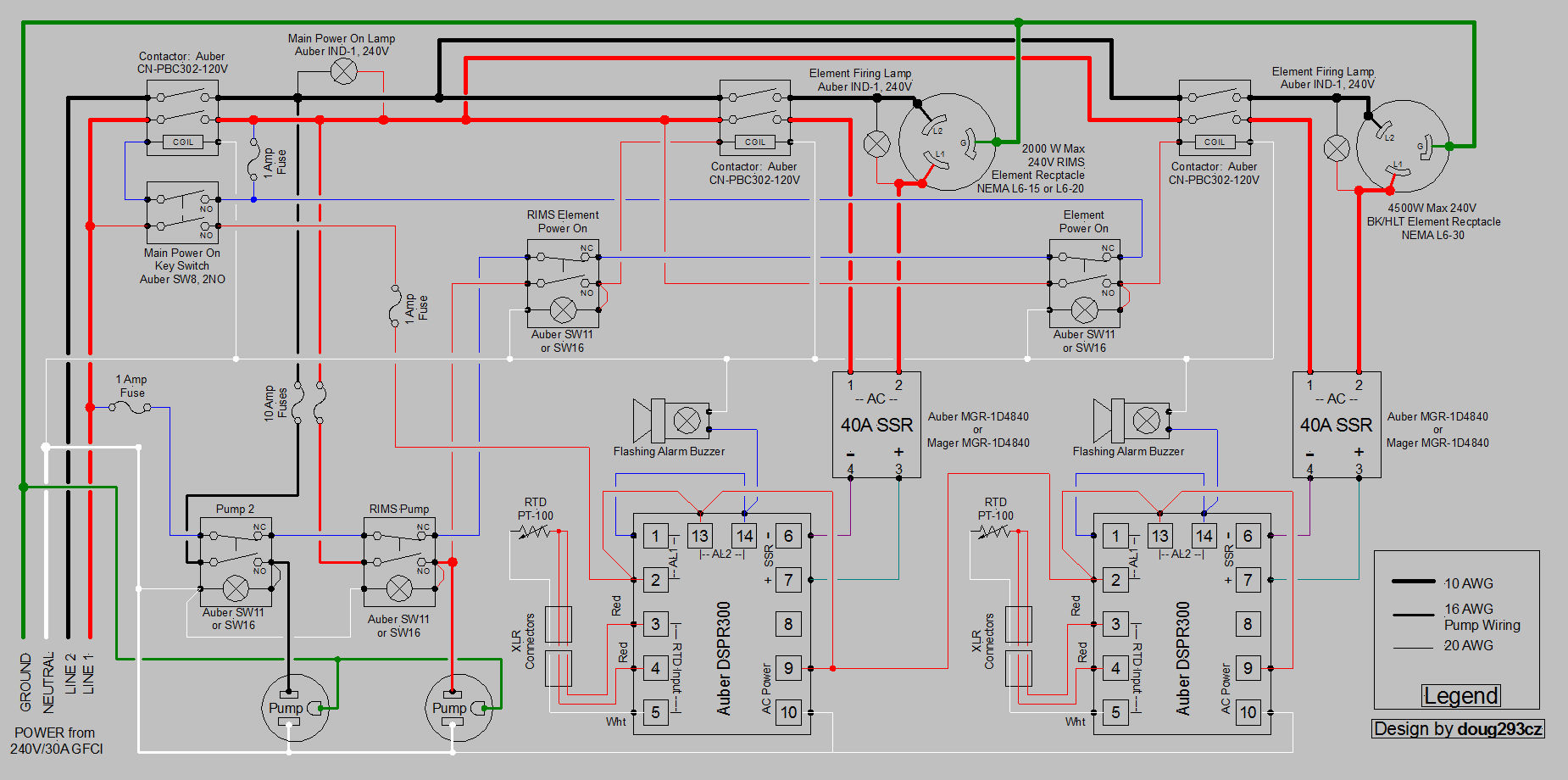

I've been doing some searching and am interested in the idea of possibly getting into a RIMS setup and also converting my boil kettle to electric. However, I don't see any prebuilt controllers available that have the ability to run both the RIMS element and a boil kettle element. This will allow the mash to run and recirculate with the RIMS element but also to heat up sparge water while the mash is running.

Does anyone have a setup like this? My current setup is 3 vessels with one propane burner. I like the idea of electric to not have to fill propane tanks and worry about the CO in the garage. Plus the temp control of RIMS is interesting.

Does anyone have a setup like this? My current setup is 3 vessels with one propane burner. I like the idea of electric to not have to fill propane tanks and worry about the CO in the garage. Plus the temp control of RIMS is interesting.

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)