I just picked up a new Brewer's Edge Mash & Boil (No, I haven't actually brewed with it yet), but since I knew I'd need some form of insulation, I experimented with a few different kinds of insulation. Even though I used the Brewer's Edge as the test bed, the results should apply to any mash tun / electric kettle.

The quick and dirty results are the following from best to worst, out of the methods I tried:

1. Stock

2. Cotton based water heater insulation

3. 3 layers of Reflectix

4. Sleeping bag

Yes, the least high tech, ended up being the best.

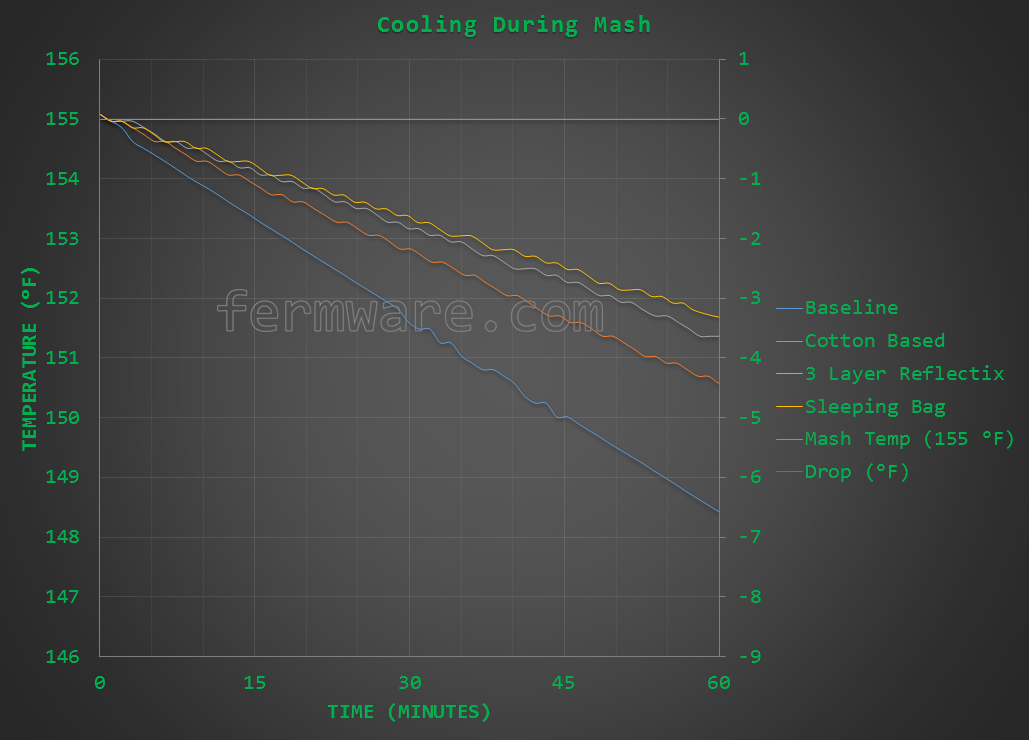

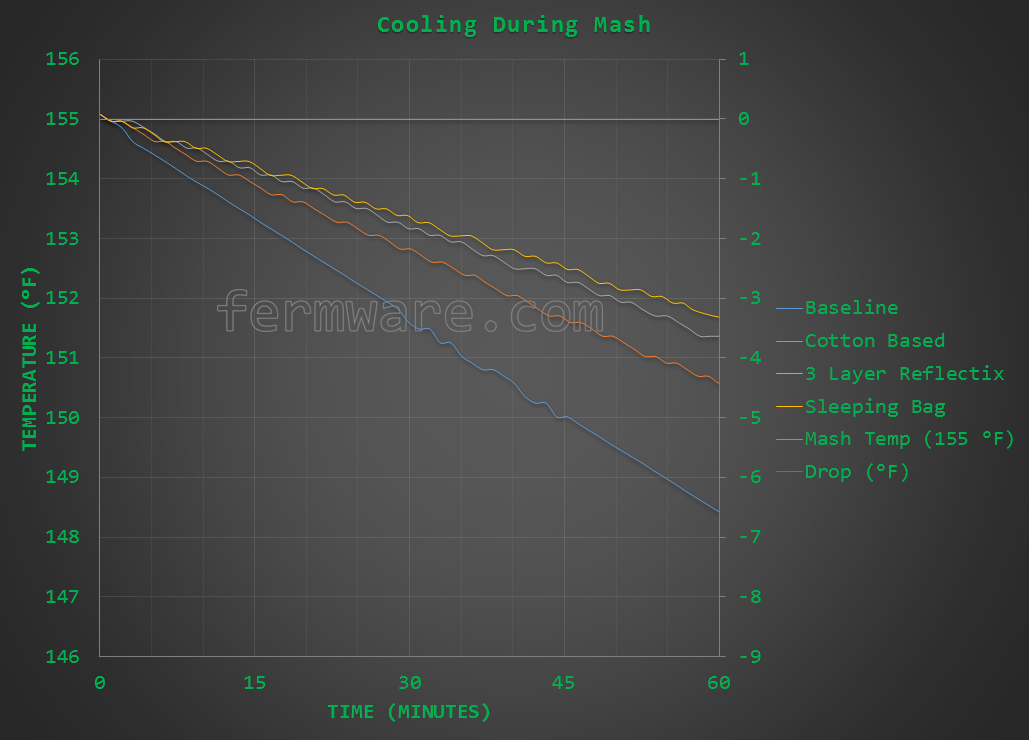

Here is a graph of temps through a simulated mash range (water only).

If you want the full run down and more graphs and info, check out the post:

http://fermware.com/mash-tun-insulation-comparisons/

The quick and dirty results are the following from best to worst, out of the methods I tried:

1. Stock

2. Cotton based water heater insulation

3. 3 layers of Reflectix

4. Sleeping bag

Yes, the least high tech, ended up being the best.

Here is a graph of temps through a simulated mash range (water only).

If you want the full run down and more graphs and info, check out the post:

http://fermware.com/mash-tun-insulation-comparisons/

![Craft A Brew - Safale BE-256 Yeast - Fermentis - Belgian Ale Dry Yeast - For Belgian & Strong Ales - Ingredients for Home Brewing - Beer Making Supplies - [3 Pack]](https://m.media-amazon.com/images/I/51bcKEwQmWL._SL500_.jpg)