diniz

Member

Hello Guys,

I finally finished to build my HERMS system.

I bought 2 Chugger Pumps and Cam Lock fittings on brewers hardware. Also, I bought a BCS-460 controller.

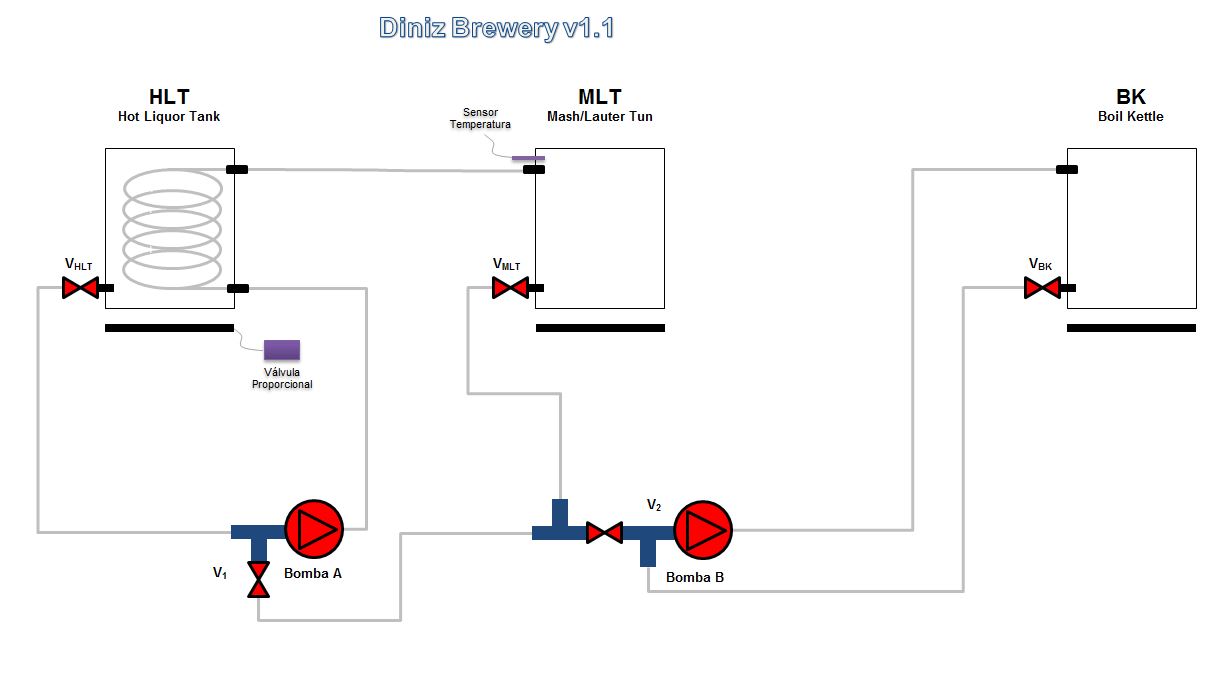

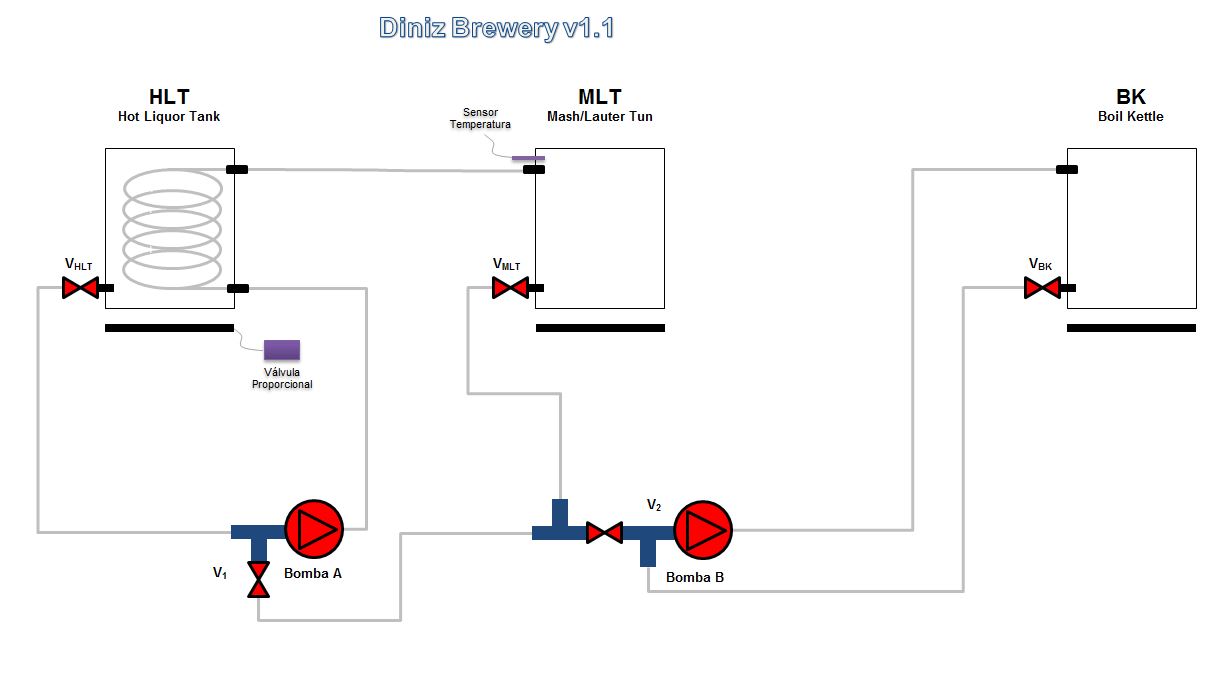

My system is presented on the pictures attached, as well as the project I built.

The system is:

* 3 kettles (Hot Liquor Tank, Mash Tun, Boil Kettle)

* The hoses are ID 3/4

* Cam Lock fittings on the kettles (High Flow)

* Barbed fittings on the pumps

But, it happens that one of the pumps is working really well, but the other one is not pumping. I'll give you more informations below:

* Pump on the left (let's call it PUMP A): It's working really well.

- There is a "Tee" with a ball valve on the inlet

* Pump on the right (let's call it PUMP B): It's not pumping

- There are two "Tee" and a ball valve on the inlet

- If I change only the housing of the pump, putting the housing of the PUMP A, it works well. If I put the impeller of the PUMP A on the housing of the PUMP B it doesn`t pump. But, if I use the impeller of the PUMP B on the housing of the PUMP A, the PUMP A still works really well.

- I am not running dry the system.

- The impeller is not broken

- I tried to remove all the "Tees" of the inlet, but still not pumping

I have no idea why this is happening.

Can you guys help me how can I fix the pump?

Thanks in advance.

Best regards,

I finally finished to build my HERMS system.

I bought 2 Chugger Pumps and Cam Lock fittings on brewers hardware. Also, I bought a BCS-460 controller.

My system is presented on the pictures attached, as well as the project I built.

The system is:

* 3 kettles (Hot Liquor Tank, Mash Tun, Boil Kettle)

* The hoses are ID 3/4

* Cam Lock fittings on the kettles (High Flow)

* Barbed fittings on the pumps

But, it happens that one of the pumps is working really well, but the other one is not pumping. I'll give you more informations below:

* Pump on the left (let's call it PUMP A): It's working really well.

- There is a "Tee" with a ball valve on the inlet

* Pump on the right (let's call it PUMP B): It's not pumping

- There are two "Tee" and a ball valve on the inlet

- If I change only the housing of the pump, putting the housing of the PUMP A, it works well. If I put the impeller of the PUMP A on the housing of the PUMP B it doesn`t pump. But, if I use the impeller of the PUMP B on the housing of the PUMP A, the PUMP A still works really well.

- I am not running dry the system.

- The impeller is not broken

- I tried to remove all the "Tees" of the inlet, but still not pumping

I have no idea why this is happening.

Can you guys help me how can I fix the pump?

Thanks in advance.

Best regards,