You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Chocolate mead anyone?

- Thread starter TacomaHomeBrew

- Start date

Help Support Homebrew Talk:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

bernardsmith

Well-Known Member

You want to look for the gravity the wine is at. If it is close to 1.000 then that means all the sugar has been converted to alcohol and CO2. If it is significantly above this then you want to see if the gravity is nevertheless dropping slowly or has stalled. If it is above 1.000 and it is stable then the yeast have stopped working. That may or may not be something you want to fix - If the gravity is at 1.010 or lower then this may be acceptably sweet. If the wine is too sweet then you will want to find a way to restart the fermentation. But you can cross that bridge if you come to it.

bernardsmith

Well-Known Member

I am currently making a gallon chocolate bouchet. I cooked 2 lbs of a local raw honey for about 3 hours in my slow cooker (did not want to burn the honey as that can result in bitter flavors) - long enough to turn the raw honey quite dark - and I added a bar of Lindt dark chocolate (65% cocoa) broken up into little pieces. The spring water I added to the honey in the slow cooker (about 3 pints ) became hot enough to melt the chocolate when I poured the water and honey mixture into my fermenting bucket. I then topped up the must with the remaining 5 pints of spring water. When the must was cool enough added 1 T of Fermaid O, rehydrated and pitched QA 23 yeast and placed the bucket in a warm water bath heated with an aquarium heater set at 78 F , then covered the bath with a thick towel to preserve the heat. It's been fermenting since 3/14. Hoping to bottle this in about a month or so with the addition of some vanilla extract I've made.

bernardsmith - that sounds good. Have you made this recipe/process before or are you just in the experiment and try it stage? Just curious if you have results to reference, or if I need to watch for your progress.

I'd like to try this myself when I have a spare jug to use (too many ideas I want to try and not enough 1 gal. jugs.)

I'd like to try this myself when I have a spare jug to use (too many ideas I want to try and not enough 1 gal. jugs.)

I'm doing something similar right now, a black forest cake bochet. I caramelized the honey for 30 min. in a pot, added water and 1 oz of unsweetened baker's chocolate then boiled for 20 min. Once that cooled I added black cherry juice and 71B yeast. That fermented for 5 days before hitting 1.01 and slowing down. Also going to add 2 vanilla beans in secondary.

$20.94

$29.99

The Brew Your Own Big Book of Clone Recipes: Featuring 300 Homebrew Recipes from Your Favorite Breweries

Amazon.com

$10.99 ($31.16 / Ounce)

Hornindal Kveik Yeast for Homebrewing - Mead, Cider, Wine, Beer - 10g Packet - Saccharomyces Cerevisiae - Sold by Shadowhive.com

Shadowhive

$44.99

$49.95

Craft A Brew - Mead Making Kit – Reusable Make Your Own Mead Kit – Yields 1 Gallon of Mead

Craft a Brew

$33.99 ($17.00 / Count)

$41.99 ($21.00 / Count)

2 Pack 1 Gallon Large Fermentation Jars with 3 Airlocks and 2 SCREW Lids(100% Airtight Heavy Duty Lid w Silicone) - Wide Mouth Glass Jars w Scale Mark - Pickle Jars for Sauerkraut, Sourdough Starter

Qianfenie Direct

$719.00

$799.00

EdgeStar KC2000TWIN Full Size Dual Tap Kegerator & Draft Beer Dispenser - Black

Amazon.com

$176.97

1pc Commercial Keg Manifold 2" Tri Clamp,Ball Lock Tapping Head,Pressure Gauge/Adjustable PRV for Kegging,Fermentation Control

hanhanbaihuoxiaoshoudian

$58.16

HUIZHUGS Brewing Equipment Keg Ball Lock Faucet 30cm Reinforced Silicone Hose Secondary Fermentation Homebrew Kegging Brewing Equipment

xiangshuizhenzhanglingfengshop

$76.92 ($2,179.04 / Ounce)

Brewing accessories 1.5" Tri Clamp to Ball Lock Post Liquid Gas Homebrew Kegging Fermentation Parts Brewer Hardware SUS304 Brewing accessories(Gas Hose Barb)

chuhanhandianzishangwu

$479.00

$559.00

EdgeStar KC1000SS Craft Brew Kegerator for 1/6 Barrel and Cornelius Kegs

Amazon.com

$53.24

1pc Hose Barb/MFL 1.5" Tri Clamp to Ball Lock Post Liquid Gas Homebrew Kegging Fermentation Parts Brewer Hardware SUS304(Liquid Hose Barb)

yunchengshiyanhuqucuichendianzishangwuyouxiangongsi

$53.24

1pc Hose Barb/MFL 1.5" Tri Clamp to Ball Lock Post Liquid Gas Homebrew Kegging Fermentation Parts Brewer Hardware SUS304(Gas Hose Barb)

Guangshui Weilu You Trading Co., Ltd

$28.98

Five Star - 6022b_ - Star San - 32 Ounce - High Foaming Sanitizer

Great Fermentations of Indiana

$22.00 ($623.23 / Ounce)

AMZLMPKNTW Ball Lock Sample Faucet 30cm Reinforced Silicone Hose Secondary Fermentation Homebrew Kegging joyful

无为中南商贸有限公司

$172.35

2 Inch Tri Clamp Keg Manifold With Ball Lock Posts, Pressure Gauge, PRV (0-30 PSI) – Homebrew, Fermentation, Kegging System

wuhanshijiayangzhiyimaoyiyouxiangongsi

$159.99 ($26.66 / Count)

3M High Flow Series System BREW120-MS, 5616001, For Brewed Coffee and Hot Tea, Valve-in-Head Design

SpaceCityProviders

$7.79 ($7.79 / Count)

Craft A Brew - LalBrew Voss™ - Kveik Ale Yeast - For Craft Lagers - Ingredients for Home Brewing - Beer Making Supplies - (1 Pack)

Craft a Brew

I stumbled on this thread looking for ideas. I know it's old, but figured I'd share what I know about chocolate from the perspective of a chocolate maker.

First, powder is created by grinding the nibs to chocolate liquor (think, unsweetened baking chocolate) then thrown into a hydraulic press to press the cocoa butter out. This process is not perfect and even under the best industrial conditions, you'll be leaving approximately 10% behind. Cocoa powder strives to be solely the cocoa solids, which give chocolate its flavor.

Cocoa nibs are generally created by cracking and winnowing cocoa beans. The cocoa beans have a paper thin husk that is very bitter and not good to eat. So after roasting (or skipping the roasting step for raw) the beans are cracked. The winnowing process is separating the cocoa nibs from the now free husk pieces, leaving you with just the cocoa bean pieces. These are generally approximately 50% cocoa butter by weight, which is why using nibs in brewing tends to be difficult at best; unless used during a boil where the cb can be melted

If you're trying to use cocoa nibs so you can control the aromatics and flavor profile of the chocolate, you will be best to roast the nibs and grind them into a thick paste. This can be very hard on most equipment. Best things I've seen that do this well is the Champion Juicer, or a wet grinder. If you have a peanut butter grinder, that will work as well. What happens here is the cocoa butter liquefies due to the friction created by the grinding and will give you a very coarse cocoa liquor. If you have the ability to, you can grind this down to refine further. While in a liquid state, you can attempt to mix this into hot water. Hot, but not boiling; just needs to keep the cocoa butter from solidifying. Once thoroughly mixed, the cocoa butter oils will likely rise to the surface and solidify.

Something to note about commercial cocoa powders; these generally are ok for baking, but not the best beans to use for cocoa flavor as they're the rejected beans (generally speaking) from chocolate production. Cocoa butter is needed in most cases, and would then be extracted from these reject beans so as to waste little to nothing. A premium producer may seek out and make a premium grade cocoa powder from normal grade beans, but in most cases these tend to have much higher fat contents sometimes 20% or more.

Boiling or getting hot water to mix cocoa powder or an unsweetened baking chocolate would be ideal. Cocoa solids because they are dried out, are quite hygroscopic, which is why it's sometimes difficult to fully soak the cocoa powder making it a messy endeavor. The solids will grab onto water and hold onto it, making a lot of the surrouding particles clump together. Breaking these clumps up, or breaking through so that the powder does more than just sit on top takes some coaxing and mixing to get done right.

Chocolate bars should only be used if you know and really trust the maker of the bars. Some premium bars can be had with 100% cocoa content (refined chocolate liquor) or 2-ingredient bars with just sugar and cocoa beans. All other ingredients that you'll want to watch for that can taint the mead or lend flavors you're not trying for include milk, butter, vanilla beans, emulsifiers (lecithin, pbpr, etc) and in some cases various spices. I almost forgot to mention, alkalizers. Dutch process cocoa powder and a lot of milk chocolates, and even some dark chocolates tend to be processed with alkalizers to neutralize the acids in the cocoa. Most commonly this is baking soda (sodium bicarbonate) Which may or may not be desired in your mead.

To figure out how much you would need, you need to keep in mind that ~50% of the nibs by weight are cocoa butter and ~10% of Hershey's natural cocoa powder is cocoa butter. So if a recipe such as the one posted earlier on this thread asks for 16oz of cocoa powder, you would need to count on needing 32oz of cocoa nibs or baking chocolate.

If you're using a chocolate bar, you should only be using a dark chocolate which will have a percentage rating. That percentage is the amount of cocoa product that's there. Because of the way labeling is, that does not mean that's the amount of cocoa solids, there can and usually is added cocoa butter to make the chocolate easier to work with. Some companies will tell you what that ratio is, some wont. Assuming it's a 2-ingredient bar, the remainder of the percentage is going to be sugar. So, using a finished chocolate bar is going to be more confusing and will be trial and error from manufacturer to manufacturer. But as a starting point, you'll again, need to at least double the cocoa solid content to what is called for in powder. So a 2oz bar that is 70% chocolate would require 22.85 bars or 48.7oz to approximate 16 oz of powder.

I'll likely be trying this using some fresh nibs, right out of the roaster and refined into a fine paste, then put into some hot water, where the chocolate liquor and water will make up the must. I'll keep you informed of how that goes if you're interested.

I hope this helps someone

First, powder is created by grinding the nibs to chocolate liquor (think, unsweetened baking chocolate) then thrown into a hydraulic press to press the cocoa butter out. This process is not perfect and even under the best industrial conditions, you'll be leaving approximately 10% behind. Cocoa powder strives to be solely the cocoa solids, which give chocolate its flavor.

Cocoa nibs are generally created by cracking and winnowing cocoa beans. The cocoa beans have a paper thin husk that is very bitter and not good to eat. So after roasting (or skipping the roasting step for raw) the beans are cracked. The winnowing process is separating the cocoa nibs from the now free husk pieces, leaving you with just the cocoa bean pieces. These are generally approximately 50% cocoa butter by weight, which is why using nibs in brewing tends to be difficult at best; unless used during a boil where the cb can be melted

If you're trying to use cocoa nibs so you can control the aromatics and flavor profile of the chocolate, you will be best to roast the nibs and grind them into a thick paste. This can be very hard on most equipment. Best things I've seen that do this well is the Champion Juicer, or a wet grinder. If you have a peanut butter grinder, that will work as well. What happens here is the cocoa butter liquefies due to the friction created by the grinding and will give you a very coarse cocoa liquor. If you have the ability to, you can grind this down to refine further. While in a liquid state, you can attempt to mix this into hot water. Hot, but not boiling; just needs to keep the cocoa butter from solidifying. Once thoroughly mixed, the cocoa butter oils will likely rise to the surface and solidify.

Something to note about commercial cocoa powders; these generally are ok for baking, but not the best beans to use for cocoa flavor as they're the rejected beans (generally speaking) from chocolate production. Cocoa butter is needed in most cases, and would then be extracted from these reject beans so as to waste little to nothing. A premium producer may seek out and make a premium grade cocoa powder from normal grade beans, but in most cases these tend to have much higher fat contents sometimes 20% or more.

Boiling or getting hot water to mix cocoa powder or an unsweetened baking chocolate would be ideal. Cocoa solids because they are dried out, are quite hygroscopic, which is why it's sometimes difficult to fully soak the cocoa powder making it a messy endeavor. The solids will grab onto water and hold onto it, making a lot of the surrouding particles clump together. Breaking these clumps up, or breaking through so that the powder does more than just sit on top takes some coaxing and mixing to get done right.

Chocolate bars should only be used if you know and really trust the maker of the bars. Some premium bars can be had with 100% cocoa content (refined chocolate liquor) or 2-ingredient bars with just sugar and cocoa beans. All other ingredients that you'll want to watch for that can taint the mead or lend flavors you're not trying for include milk, butter, vanilla beans, emulsifiers (lecithin, pbpr, etc) and in some cases various spices. I almost forgot to mention, alkalizers. Dutch process cocoa powder and a lot of milk chocolates, and even some dark chocolates tend to be processed with alkalizers to neutralize the acids in the cocoa. Most commonly this is baking soda (sodium bicarbonate) Which may or may not be desired in your mead.

To figure out how much you would need, you need to keep in mind that ~50% of the nibs by weight are cocoa butter and ~10% of Hershey's natural cocoa powder is cocoa butter. So if a recipe such as the one posted earlier on this thread asks for 16oz of cocoa powder, you would need to count on needing 32oz of cocoa nibs or baking chocolate.

If you're using a chocolate bar, you should only be using a dark chocolate which will have a percentage rating. That percentage is the amount of cocoa product that's there. Because of the way labeling is, that does not mean that's the amount of cocoa solids, there can and usually is added cocoa butter to make the chocolate easier to work with. Some companies will tell you what that ratio is, some wont. Assuming it's a 2-ingredient bar, the remainder of the percentage is going to be sugar. So, using a finished chocolate bar is going to be more confusing and will be trial and error from manufacturer to manufacturer. But as a starting point, you'll again, need to at least double the cocoa solid content to what is called for in powder. So a 2oz bar that is 70% chocolate would require 22.85 bars or 48.7oz to approximate 16 oz of powder.

I'll likely be trying this using some fresh nibs, right out of the roaster and refined into a fine paste, then put into some hot water, where the chocolate liquor and water will make up the must. I'll keep you informed of how that goes if you're interested.

I hope this helps someone

Reviving an old thread, has anyone tried Cholaca in a mead? I know it’s used by many breweries in their beers containing chocolate.

I will say I am not a fan of cocoa powder.

Eric Carman

New Member

- Joined

- May 11, 2020

- Messages

- 1

- Reaction score

- 0

Would u be able to shoot me that recipe for the 5 gallon also have u tried to back sweeten this before aging so long to kill the bitternessWhat is the recipe?

well it looks like this thread has been around for about 8 years and occasionally it gets bumped back up with a newb like me, or a new question.

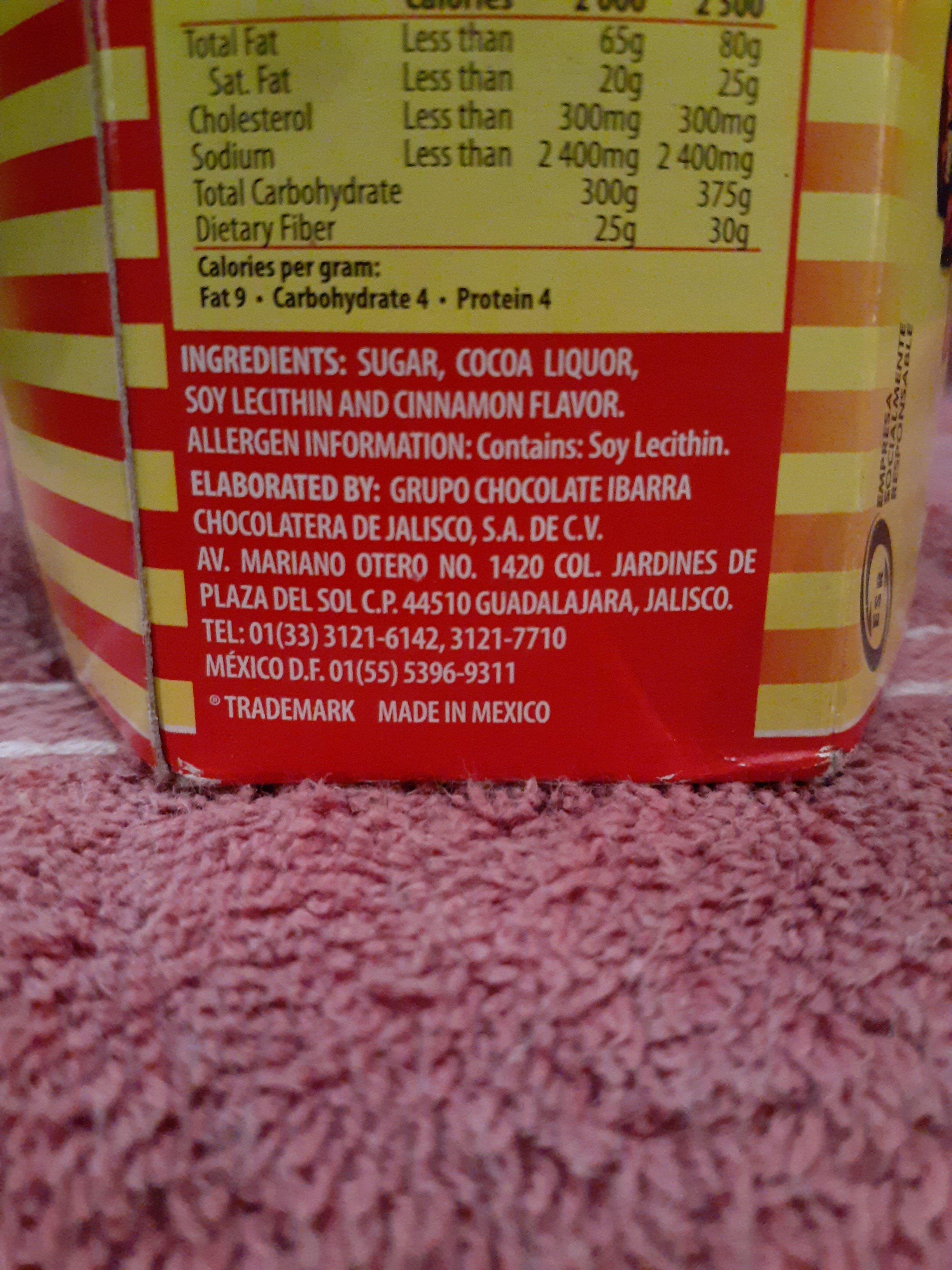

I've read through the entire thread, and I was particularly interested in the gentleman who offered his thoughts from the perspective of a Chocolate Maker. so I thought I'd bring it around once again, and see if anyone has any thoughts on this... Has anyone ever tried using Ibarra Mexican Chocolate bars for making hot chocolate drinks ?

It has 4 ingredients : Sugar, Cocoa Liquor, Soy Lecithin, and cinnamon flavor.

I'm just wondering if this might be an easy way to make a Chocolate Mead ?

and if so,

How would those experienced in making Chocolate Meads go about using this ?

I've read through the entire thread, and I was particularly interested in the gentleman who offered his thoughts from the perspective of a Chocolate Maker. so I thought I'd bring it around once again, and see if anyone has any thoughts on this... Has anyone ever tried using Ibarra Mexican Chocolate bars for making hot chocolate drinks ?

It has 4 ingredients : Sugar, Cocoa Liquor, Soy Lecithin, and cinnamon flavor.

I'm just wondering if this might be an easy way to make a Chocolate Mead ?

and if so,

How would those experienced in making Chocolate Meads go about using this ?

bernardsmith

Well-Known Member

Couple of quick thoughts. Everything you add to a mead or wine must have a good reason. What would be the reason to add soy lecithin? My guess is that it is added in commercial products as an emulsifier and in a mead what would be the good sense of adding an emulsifier?

It's not easy to create a chocolate flavored mead or wine because the flavor of chocolate that we are all familiar with tends to involve cocoa butter and not simply cocoa and you really want to avoid adding any fats to a wine for two reasons. The first is that fats tend to coat your carboys and tubes and are a bitch to remove and the second is because fats tend to become rancid with age.

Now you can obtain a reasonably fair chocolate flavor using roasted cocoa nibs, but the flavor the nibs impart is not one I think of as perfectly desireable. I prefer to add chocolate barley malt (as in brewing). The heavily roasted malted grains provide no fermentable sugars (they are too cooked) but they do impart a very rich chocolate flavor (think- chocolate stouts). I think 2 oz per gallon of these cracked grains added to the secondary with nibs in the primary produce a delightful chocolate flavored mead. The use of cocoa powder, in my opinion, always tends to produce a drink that never clears.

One other option, which I have yet to try is to use Torani chocolate syrup. I do add this syrup to spirits to make chocolate liqueurs but that is another story.

It's not easy to create a chocolate flavored mead or wine because the flavor of chocolate that we are all familiar with tends to involve cocoa butter and not simply cocoa and you really want to avoid adding any fats to a wine for two reasons. The first is that fats tend to coat your carboys and tubes and are a bitch to remove and the second is because fats tend to become rancid with age.

Now you can obtain a reasonably fair chocolate flavor using roasted cocoa nibs, but the flavor the nibs impart is not one I think of as perfectly desireable. I prefer to add chocolate barley malt (as in brewing). The heavily roasted malted grains provide no fermentable sugars (they are too cooked) but they do impart a very rich chocolate flavor (think- chocolate stouts). I think 2 oz per gallon of these cracked grains added to the secondary with nibs in the primary produce a delightful chocolate flavored mead. The use of cocoa powder, in my opinion, always tends to produce a drink that never clears.

One other option, which I have yet to try is to use Torani chocolate syrup. I do add this syrup to spirits to make chocolate liqueurs but that is another story.

Bernardsmith,

Thank you very much for the reply.

I had not thought about how the Soy Lecithin could contaminate the fermentation or racking vessel.

I will try an experiment with the Torani syrup.

I love the idea of a chocolate flavored Mead, but would also like to find a way to do it without the 1 to 2 year wait.

Right now I am new to making Mead and want to see some quick results. I'm sure that as I get more into the finer aspects of crafting this wonderful drink, my patience will develop and I'll be more willing to wait on the finer methods that are already proven.

Thank you again for your thoughts and advice.

Cheers

Thank you very much for the reply.

I had not thought about how the Soy Lecithin could contaminate the fermentation or racking vessel.

I will try an experiment with the Torani syrup.

I love the idea of a chocolate flavored Mead, but would also like to find a way to do it without the 1 to 2 year wait.

Right now I am new to making Mead and want to see some quick results. I'm sure that as I get more into the finer aspects of crafting this wonderful drink, my patience will develop and I'll be more willing to wait on the finer methods that are already proven.

Thank you again for your thoughts and advice.

Cheers

bernardsmith

Well-Known Member

I may be a contrarian but in my opinion any wine or mead that is undrinkable for more than a year has been poorly made***. That all well-made wines improve dramatically as they age is not at all the same thing. But that change is what makes a good wine a great one, not a poor wine a barely acceptable one. If a recipe or those who make it say that you need to wait at least a year before the flavors become muted enough to enjoy then I would reject the protocol. In my opinion, a mead when made well, using good practices, can be enjoyed after even 3 months. After 6 months it might be transformed into a delicious drink and after 12 it should be incredible. But every mead (or wine) should be delightful shortly after it has cleared bright.

*** The one exception might be where you are oaking the mead or wine in barrels. Commercial wineries using barrels to oak their wines may need years to extract the flavors, but most home wine amkers add oak cubes or spirals to their wines and the surface area of the wood in contact with the wine is magnitudes greater, so the time needed to extract the same amount of flavors is considerably less (which is not to claim that there are no significant advantages to the longer process, eg micro-oxidation).

*** The one exception might be where you are oaking the mead or wine in barrels. Commercial wineries using barrels to oak their wines may need years to extract the flavors, but most home wine amkers add oak cubes or spirals to their wines and the surface area of the wood in contact with the wine is magnitudes greater, so the time needed to extract the same amount of flavors is considerably less (which is not to claim that there are no significant advantages to the longer process, eg micro-oxidation).

jimidenooyer

New Member

- Joined

- Jan 8, 2021

- Messages

- 1

- Reaction score

- 0

Hi Rebecca, can I get your chocolate cherry mead recipe? It sounds delicious!I make a Chocolate Cherry mead that I get raves on, but my recipe is for a 5 gallon batch. There are quite a few people who make chocolate meads around here, so I'll let someone else post a tried and true one gallon recipe.

I just wanted to warn you that chocolate meads take a long time to age. One year before you even want to think about bottling and another 6 months (closer to two years) before it hits its stride. The oils take a long time to break down and it is gawd awful bitter in the meantime. When I made my first batch it took the whole first year for me to convince my DB that it was going to be great. Fact is, I even started to doubt it. Now it is one of our favorites and I try to make at lease one batch every year so we stop running out.

Good Luck.

Rebecca

Recognizing you're a new member here, heads-up, when you hover over Rebecca's avatar (or her member's name) you can see an information pop-up telling us she hasn't been on this forum since March 2017. So... don't hold your breath for an answer.Hi Rebecca, can I get your chocolate cherry mead recipe? It sounds delicious!

But on her subsequent post (#7) she did tell us how she used the chocolate.

@AkTom....It's been 3 long years, (almost to the day) how did your 1 gallon batch from 2017 come out? Just curious if it lasted this long

Funny you should ask. I still have it. I forget my process on it. It had dry cocoa... not very tasty. Took forever to clear.

It is still dropping Lee’s.

Looks nice. Thank for taking time to replyView attachment 714028

It is still dropping Lee’s.

There’s a 2 part chopandbrew episode with Steve Fletty…I know I'm kicking an old thread here but does anyone have any experience using cocoa nibs instead of the powder? I am trying to find information on using NIBS and I am having the hardest time finding anything

Hottwheels117

New Member

Would you be willing to share your recipe for the 5 gallon? If not I completely understandI make a Chocolate Cherry mead that I get raves on, but my recipe is for a 5 gallon batch. There are quite a few people who make chocolate meads around here, so I'll let someone else post a tried and true one gallon recipe.

I just wanted to warn you that chocolate meads take a long time to age. One year before you even want to think about bottling and another 6 months (closer to two years) before it hits its stride. The oils take a long time to break down and it is gawd awful bitter in the meantime. When I made my first batch it took the whole first year for me to convince my DB that it was going to be great. Fact is, I even started to doubt it. Now it is one of our favorites and I try to make at lease one batch every year so we stop running out.

Good Luck.

Rebecca

@Hottwheels117 This post is from 2012. Gamrchick was last on the forum in Feb. of this year. So it might be a long time before you get a reply.

![Craft A Brew - Safale BE-256 Yeast - Fermentis - Belgian Ale Dry Yeast - For Belgian & Strong Ales - Ingredients for Home Brewing - Beer Making Supplies - [3 Pack]](https://m.media-amazon.com/images/I/51bcKEwQmWL._SL500_.jpg)