Any cheaper options than a March/Chugger for recirculating hot water in an eHLT? I can't seem to find anything with a high enough temp rating and a high flow. There are a number of high temp pumps on Amazon for sous vide cooking, but they either only go up to 80C or are like 1L/min.

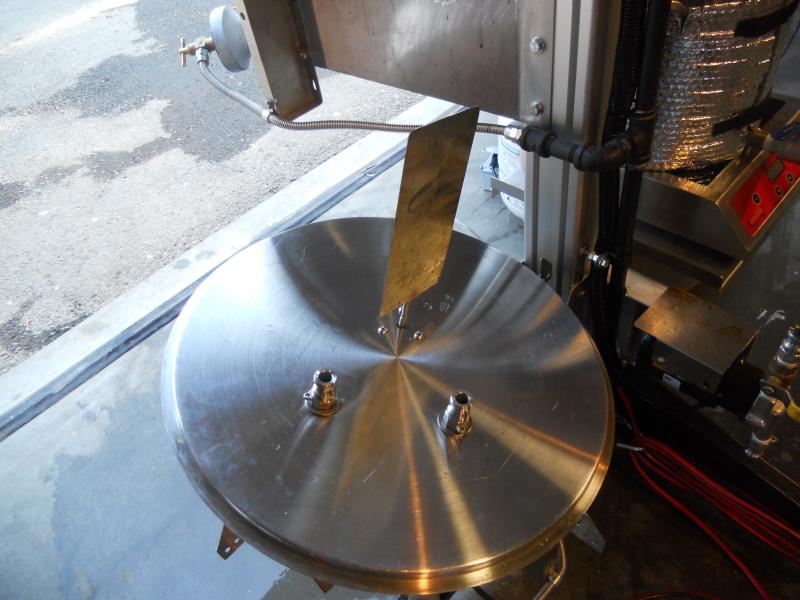

Those stirring pumps seem clumsy to me, and I like the idea of measuring the HLT water temperature at the outlet of a recirculation like Kal has done on his electric brewery.

Those stirring pumps seem clumsy to me, and I like the idea of measuring the HLT water temperature at the outlet of a recirculation like Kal has done on his electric brewery.