You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Cheap & Easy 10 Gallon Rubbermaid MLT Conversion

- Thread starter FlyGuy

- Start date

Help Support Homebrew Talk:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

cactusgarrett

Well-Known Member

Again, thanks to everyone who's contributed to this thread. Just wanted to throw in some info: I know the SS washers have been a pain to find. One word: Fastenal. If you have one in your area, that's where you should go for ANY sized washer. I walked in and out in 3min with everything i needed.

Again, thanks to everyone who's contributed to this thread. Just wanted to throw in some info: I know the SS washers have been a pain to find. One word: Fastenal. If you have one in your area, that's where you should go for ANY sized washer. I walked in and out in 3min with everything i needed.

yup...I've only posted the link with store locations, website ordering and the actual fastenal skew number for the washer 3 or 4 times in this thread...

Glas you found the washers

cactusgarrett

Well-Known Member

Just wanted to bring it to the forefront so suckas like me don't have to spend 1/2hour reading thru 23 pages of posts and getting turned around 12 times after changing plans, sizes, etc. blah blah blah.

Skrimpy

Well-Known Member

yup...I've only posted the link with store locations, website ordering and the actual fastenal skew number for the washer 3 or 4 times in this thread...

Glas you found the washers

Shoulda opened my eyes.

sku is...71225

Im gonna head over there before my next batch. its just up the road from me!

FEARDIZ

Well-Known Member

thanks for the Fastenal tip, I've been going to 3 different Ace, Home depot, lowes, and I'm about to punch somone if they don't give me a SS 5/8 fender washer

Lowes has steel / zinc washers, and 3/4 SS fender but not 5/8

Also my rectangle cooler needs a longer nipple, so I got the 2 inch and the 2.25 inch just to be sure something fits

I'll goto Fastenal tommorow, there are a few in the area

UGG !!!

Lowes has steel / zinc washers, and 3/4 SS fender but not 5/8

Also my rectangle cooler needs a longer nipple, so I got the 2 inch and the 2.25 inch just to be sure something fits

I'll goto Fastenal tommorow, there are a few in the area

UGG !!!

$20.94

$29.99

The Brew Your Own Big Book of Clone Recipes: Featuring 300 Homebrew Recipes from Your Favorite Breweries

Amazon.com

$53.24

1pc Hose Barb/MFL 1.5" Tri Clamp to Ball Lock Post Liquid Gas Homebrew Kegging Fermentation Parts Brewer Hardware SUS304(Gas MFL)

Guangshui Weilu You Trading Co., Ltd

$33.99 ($17.00 / Count)

$41.99 ($21.00 / Count)

2 Pack 1 Gallon Large Fermentation Jars with 3 Airlocks and 2 SCREW Lids(100% Airtight Heavy Duty Lid w Silicone) - Wide Mouth Glass Jars w Scale Mark - Pickle Jars for Sauerkraut, Sourdough Starter

Qianfenie Direct

$53.24

1pc Hose Barb/MFL 1.5" Tri Clamp to Ball Lock Post Liquid Gas Homebrew Kegging Fermentation Parts Brewer Hardware SUS304(Liquid Hose Barb)

yunchengshiyanhuqucuichendianzishangwuyouxiangongsi

$33.95

Five Star - 6022b_ - Star San - 32 Ounce - High Foaming Sanitizer

Bridgeview Beer and Wine Supply

$39.22 ($39.22 / Count)

Brewer's Best Home Brew Beer Ingredient Kit - 5 Gallon (Mexican Cerveza)

Amazon.com

$10.99 ($31.16 / Ounce)

Hornindal Kveik Yeast for Homebrewing - Mead, Cider, Wine, Beer - 10g Packet - Saccharomyces Cerevisiae - Sold by Shadowhive.com

Shadowhive

$58.16

HUIZHUGS Brewing Equipment Keg Ball Lock Faucet 30cm Reinforced Silicone Hose Secondary Fermentation Homebrew Kegging Brewing Equipment

xiangshuizhenzhanglingfengshop

$176.97

1pc Commercial Keg Manifold 2" Tri Clamp,Ball Lock Tapping Head,Pressure Gauge/Adjustable PRV for Kegging,Fermentation Control

hanhanbaihuoxiaoshoudian

$7.79 ($7.79 / Count)

Craft A Brew - LalBrew Voss™ - Kveik Ale Yeast - For Craft Lagers - Ingredients for Home Brewing - Beer Making Supplies - (1 Pack)

Craft a Brew

$22.00 ($623.23 / Ounce)

AMZLMPKNTW Ball Lock Sample Faucet 30cm Reinforced Silicone Hose Secondary Fermentation Homebrew Kegging joyful

无为中南商贸有限公司

Skrimpy

Well-Known Member

thanks for the Fastenal tip, I've been going to 3 different Ace, Home depot, lowes, and I'm about to punch somone if they don't give me a SS 5/8 fender washer

Lowes has steel / zinc washers, and 3/4 SS fender but not 5/8

Also my rectangle cooler needs a longer nipple, so I got the 2 inch and the 2.25 inch just to be sure something fits

I'll goto Fastenal tommorow, there are a few in the area

UGG !!!

punch someone is right! For the most part dudes just look and say "5/8", no way is ANYONE going to have one that big, I don't even think they are manufactured. What do you want to do and maybe I can find a substitute", and then when you say the words "food grade in conjunction with corrosion resistent", they just about lose their mind...and then forget about even speaking to them when find out you want to put it over a 5/8" OD copper nipple instead of a 5/8" bolt. They just look at you like you are crazy. Maybe we are.

Speaking of the MLT, I did my first AG batch with it and it went pretty well. I used a turkey fryer to do the boil but had to bring the boil up to 5 gallons because I didn't get enough out of the mash. I made EdWort Haus Pale Ale at the suggestion of another member. It's been in the primary for almost a week now and the krausen fell after day 3. Day 2 was interesting because the krausen came right through the airlock and the beer was an opaque YELLOW. None of my batches have been that color. It has turned a nice golden brown color since. I pulled the airlock, santized the top of it and left it sitting on top of the fermenter (twice). I guess I should have purchased a blow off tube. I didn't think the fermentation was going to be that vigerous. I'm racking to the 2ndary tomorrow (1 week). If this beer turns out good I may never make anything else (good God I love pale ale).

punch someone is right! For the most part dudes just look and say "5/8", no way is ANYONE going to have one that big, I don't even think they are manufactured. What do you want to do and maybe I can find a substitute", and then when you say the words "food grade in conjunction with corrosion resistent", they just about lose their mind...and then forget about even speaking to them when find out you want to put it over a 5/8" OD copper nipple instead of a 5/8" bolt. They just look at you like you are crazy. Maybe we are.

Speaking of the MLT, I did my first AG batch with it and it went pretty well. I used a turkey fryer to do the boil but had to bring the boil up to 5 gallons because I didn't get enough out of the mash. I made EdWort Haus Pale Ale at the suggestion of another member. It's been in the primary for almost a week now and the krausen fell after day 3. Day 2 was interesting because the krausen came right through the airlock and the beer was an opaque YELLOW. None of my batches have been that color. It has turned a nice golden brown color since. I pulled the airlock, santized the top of it and left it sitting on top of the fermenter (twice). I guess I should have purchased a blow off tube. I didn't think the fermentation was going to be that vigerous. I'm racking to the 2ndary tomorrow (1 week). If this beer turns out good I may never make anything else (good God I love pale ale).

I was lucky...the guy at home depot actually told me about Fastenal...never heard of it before...Lesson for the future, when you go to a big box store look for the oldest guy working there and ask HIM your question...1) he might actually know what you are talking about 2) he might be willing to think beyond his current task and be willing to help rather than get his job done, or get rid of the nagging customer so he can have a cigarette and 3) he might know a competitor who would carry something you are looking for and be willing to tell you about it.

Skrimpy

Well-Known Member

...look for the oldest guy working there and ask HIM your question...

Yeah. Look for the retired plumber that is working there to supplament his pension and get health insurance.

Philip1993

Well-Known Member

- Joined

- Jul 5, 2007

- Messages

- 1,644

- Reaction score

- 19

If it helps anyone, I DO NOT have any washers on my cooler (inside or out) and it doesn't leak. I bought a 1" nipple (iirc) and put a hose barb fitting on the inside. Pushed that through the rubber grommet that came with the cooler (5gal rubbermaid, round), and screwed the ball valve on the outside until it compressed the grommet from the outside.

Works like a champ for me. No washers, no silicone, and so far (1 - 24hr test, 2 pre-heats, 2 batches) not a drop leaked.

Works like a champ for me. No washers, no silicone, and so far (1 - 24hr test, 2 pre-heats, 2 batches) not a drop leaked.

If it helps anyone, I DO NOT have any washers on my cooler (inside or out) and it doesn't leak. I bought a 1" nipple (iirc) and put a hose barb fitting on the inside. Pushed that through the rubber grommet that came with the cooler (5gal rubbermaid, round), and screwed the ball valve on the outside until it compressed the grommet from the outside.

Works like a champ for me. No washers, no silicone, and so far (1 - 24hr test, 2 pre-heats, 2 batches) not a drop leaked.

This

Post

is

Useless

Without

Pictures!

Seriously I'd like ot see what you did.

Philip1993

Well-Known Member

- Joined

- Jul 5, 2007

- Messages

- 1,644

- Reaction score

- 19

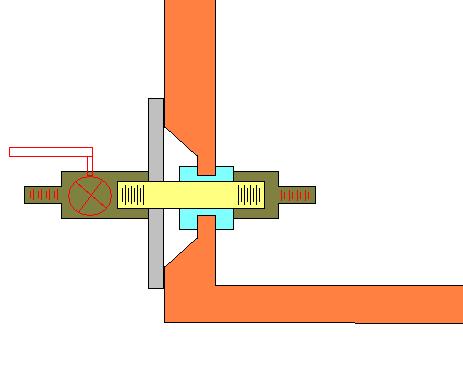

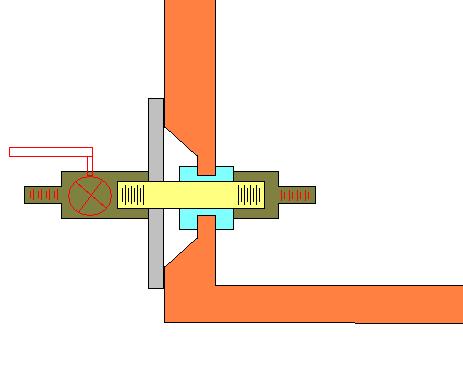

I'll try and get some later today. In the meantime, here's a really bad drawing.

One thing, I just pulled it out and I remembered that I did go back and put a 5/8" fender washer (non-SS from Lowes) on the outside (only). Not because it was leaking, but because you could twist the valve handle and rotate the spigot/ball valve inside the grommet. I was afraid over time this might allow the valve to wear out or tear the outer lip of the grommet. Since the grommet is not easily replaced, I added the washer to take the damage.

One thing, I just pulled it out and I remembered that I did go back and put a 5/8" fender washer (non-SS from Lowes) on the outside (only). Not because it was leaking, but because you could twist the valve handle and rotate the spigot/ball valve inside the grommet. I was afraid over time this might allow the valve to wear out or tear the outer lip of the grommet. Since the grommet is not easily replaced, I added the washer to take the damage.

FEARDIZ

Well-Known Member

I got to Fastenal and got my washers, part # 1171026

I have a few extras now, if anyone wants some let me know

I put everything together and no leaks yet. It's filled with 120 deg water, I'll wait an hour or so for any leaks and see how much heat loss I get.

so I waited over an hour no heat loss at 120 deg.. maybe a drip or two, nothing to worry about

going all grain this weekend

I have a few extras now, if anyone wants some let me know

I put everything together and no leaks yet. It's filled with 120 deg water, I'll wait an hour or so for any leaks and see how much heat loss I get.

so I waited over an hour no heat loss at 120 deg.. maybe a drip or two, nothing to worry about

going all grain this weekend

FEARDIZ

Well-Known Member

i just tried my MLT cooler ( 1st all grain ) the wort was not going thru the braid, it was a real PIA.. any suggestions?

Philip1993

Well-Known Member

- Joined

- Jul 5, 2007

- Messages

- 1,644

- Reaction score

- 19

Was it stainless and not plastic?

Ok, did it flow with plain hot water?

If both, it was your crush. That is called a stuck sparge.

Ok, did it flow with plain hot water?

If both, it was your crush. That is called a stuck sparge.

FEARDIZ

Well-Known Member

yes it worked with plain water, the braid is stainless

Try not opening the valve all the way. I haven't had a stuck sparge yet, but as a preventative measure I put the handle on my ball valve to about 45* (halfway). At full flow the same suction that makes a good grain "filter" can compact it.

Philip1993

Well-Known Member

- Joined

- Jul 5, 2007

- Messages

- 1,644

- Reaction score

- 19

yes it worked with plain water, the braid is stainless

Well, then it's not your equipment. Follow advice given and search on "stuck sparge"

TwoHeadsBrewing

Well-Known Member

yes it worked with plain water, the braid is stainless

This happened to me after 3 batches...the first 3 went fine, then got some sort of blockage. I could easily blow air back through the valve and SS braid, but hardly any wort would come out! I'm not 100% sure what the problem was, but I think the tubing was collapsing right where it joined the barbed connector.

I fixed this by getting 1 foot of 1/2" copper tubing, and a couple 45 degree elbows. Now I have the copper tubing equivalent of the SS braid...and works great so far! I think the copper parts ran me all of 5 bucks...1/16" drill bit was $2.39 for two bits. Come to think of it, this option might actually be cheaper than the SS braid system

FEARDIZ

Well-Known Member

This happened to me after 3 batches...the first 3 went fine, then got some sort of blockage. I could easily blow air back through the valve and SS braid, but hardly any wort would come out! I'm not 100% sure what the problem was, but I think the tubing was collapsing right where it joined the barbed connector.

I fixed this by getting 1 foot of 1/2" copper tubing, and a couple 45 degree elbows. Now I have the copper tubing equivalent of the SS braid...and works great so far! I think the copper parts ran me all of 5 bucks...1/16" drill bit was $2.39 for two bits. Come to think of it, this option might actually be cheaper than the SS braid system.

yep same issue, I could blow back into the braid, and it would clear it up for a sec or two, then nothing again. I used my spoon to clear the grain away from the braid, and it still was not working. I ended up cutting the baid off to get the wort out

TwoHeadsBrewing

Well-Known Member

yep same issue, I could blow back into the braid, and it would clear it up for a sec or two, then nothing again. I used my spoon to clear the grain away from the braid, and it still was not working. I ended up cutting the baid off to get the wort out

HAHA, I don't feel so bad now...I did the exact same thing! I figure that the tubing I was using was just getting fatigued over time...and by that fourth batch, it just collapsed under the weight of the mash. I toyed with the idea of getting a thicker tubing (same ID, bigger OD), or some nylon reinforced stuff...but the copper was cheap, so I went that route.

Medo

Well-Known Member

Ahoy hoy,

This thread sure came in handy last night. My normal cooler mashtun had a flaw and it finally failed last night. Needless to say I was in shock, and high and dry. It had always been my intention to move up in size so i could do 10 gallon batches, as the 48 qt cooler i used was really maxed out doing anything close. So, using Fly Boys plans as a base guide, I "modified" them to work with a coleman extreme 60qt cooler. The hole size was 3/4" so I compensated for that, and put together a deal that let me use my stickless sparge manifold in this new cooler. Its the same width as the old one, just a big longer. so it worked fine.

(FYI my sparge manifold is made out of 7/8" diameter stainless steel screen hose, ie bazooka hose. I have it connected together with cpvc fittings and it is a beast that never plugs.) At this point, the only weakpoint is that even with the manifold sitting flush on the bottom, when all is said and done about 1 1/2 qts of water remain after full drain, due to the larger sq inch size of the bottom of the cooler. I can deal with that.

But, it was Fly Boys pictures and ideas that led me to be able to slap it together with such ease, with minor tweaks.

So thanks flyboy, and, to folks who have larger coleman coolers at your disposal,(10 gallon rubbermaids are few and far between up here in interior Alaska ) they work pretty freakin good if you take the time to set them up. and the extreme model holds heat like cast iron.

I bid you all a great day. Brew on.....

This thread sure came in handy last night. My normal cooler mashtun had a flaw and it finally failed last night. Needless to say I was in shock, and high and dry. It had always been my intention to move up in size so i could do 10 gallon batches, as the 48 qt cooler i used was really maxed out doing anything close. So, using Fly Boys plans as a base guide, I "modified" them to work with a coleman extreme 60qt cooler. The hole size was 3/4" so I compensated for that, and put together a deal that let me use my stickless sparge manifold in this new cooler. Its the same width as the old one, just a big longer. so it worked fine.

(FYI my sparge manifold is made out of 7/8" diameter stainless steel screen hose, ie bazooka hose. I have it connected together with cpvc fittings and it is a beast that never plugs.) At this point, the only weakpoint is that even with the manifold sitting flush on the bottom, when all is said and done about 1 1/2 qts of water remain after full drain, due to the larger sq inch size of the bottom of the cooler. I can deal with that.

But, it was Fly Boys pictures and ideas that led me to be able to slap it together with such ease, with minor tweaks.

So thanks flyboy, and, to folks who have larger coleman coolers at your disposal,(10 gallon rubbermaids are few and far between up here in interior Alaska ) they work pretty freakin good if you take the time to set them up. and the extreme model holds heat like cast iron.

I bid you all a great day. Brew on.....

peppermintoj

New Member

- Joined

- Jul 30, 2008

- Messages

- 2

- Reaction score

- 0

Hey flyguy you seem pretty handy. have you done anything for a sparge arm? and also how about your wort chiller? my friend and i are bouncing back and forth on a normal wort chiller and also a counter fed one.

I got my 10 gal. cooler at Sportsmans warehouse $39.95 over the weekend.

Same for me -- same price at the local Sportsmans Warehouse. I decided that I'm going to give the all grain thing a try. Before I can do this, I need to acquire a few things and decided to start with this. Hopefully sometime this fall I'll be ready to give it a whirl. Thanks FlyGuy for the very useful instructions and to everyone else for the useful comments and advice!

theforrest

New Member

- Joined

- Jul 31, 2008

- Messages

- 2

- Reaction score

- 0

So from what I've gleened from the previous posts, using the SS braid will usually work but may wear down after a few batches? Would you all recommend just making a copper manifold then?

TwoHeadsBrewing

Well-Known Member

I can only speak for myself, but the tubing I used did in fact wear down after 4-5 batches. I'm not sure if I used the wrong kind of tubing, but it just collapsed after a few uses. If you used nylon reinforced tubing, or thick-walled tubing you might not have this problem. My opinion is to go with a simple copper tube with holes in it.

I built my 10 Gallon MLT following the directions above, but I used Oetiker stainless steel clamps on the hose ends and another 3/8" nipple with a plug in the end for weight on the free side of the hose.

Looking forward to trying this MLT out.

Looking forward to trying this MLT out.

SilverKing

Well-Known Member

I'm brand new here and the DIY forum really has me hooked. Many interesting projects in here.

I just brewed my first AG batch last weekend. Everything went quite smoothly, thanks in part to my MLT. It's nearly identical to the original poster, but I wrapped the SS braid back around. I'm sure that's been mentioned already in this monster thread.

couple pics just because:

I just brewed my first AG batch last weekend. Everything went quite smoothly, thanks in part to my MLT. It's nearly identical to the original poster, but I wrapped the SS braid back around. I'm sure that's been mentioned already in this monster thread.

couple pics just because:

FlyGuy

Well-Known Member

No sparge arm yet -- I have only used the MLT for batch sparging. I am too lazy to learn continuous sparging now! But I may try in the future. When I do, I probably won't bother with a sparge arm -- I will just make a circular manifold out of copper tubing, drill some holes in it, and set it on the top of the grainbed.Hey flyguy you seem pretty handy. have you done anything for a sparge arm? and also how about your wort chiller? my friend and i are bouncing back and forth on a normal wort chiller and also a counter fed one.

I am really not sure why there are people having the braid fail on them. I have made three of these MLTs, and used the cheapest ($3) dollar braid I could find, and after many, many batches, I have yet to have a braid collapse. My guess is that people are using nylon/plastic braids instead of stainless. They look identical, but don't perform the same at all.So from what I've gleened from the previous posts, using the SS braid will usually work but may wear down after a few batches? Would you all recommend just making a copper manifold then?

- Joined

- Jun 2, 2008

- Messages

- 64,955

- Reaction score

- 16,524

Well after trips to both home depot and lowe's, I'm still short the 10-gallon cooler and the SS washers. I'll hit ACE this afternoon -- or it's off to the internet. Thanks for the great write up FlyGuy!

p.s. Lowe's didn't have a threaded ball valve, so I bought the unthreaded one on accident. oops. But Home Depot had the threaded one.

p.s.s. I'm pretty excited to be going all-grain and am no longer "afraid" of terms like strike water, mash, sparge, lauter, dough in, vorlauf, mash efficiency, sparge efficiency, and Bobby_M's N.M.O.D.B.S.

p.s. Lowe's didn't have a threaded ball valve, so I bought the unthreaded one on accident. oops. But Home Depot had the threaded one.

p.s.s. I'm pretty excited to be going all-grain and am no longer "afraid" of terms like strike water, mash, sparge, lauter, dough in, vorlauf, mash efficiency, sparge efficiency, and Bobby_M's N.M.O.D.B.S.

Similar threads

- Replies

- 3

- Views

- 474

Colorado

Nano Homebrew System (10-15 Gallons)

- Replies

- 0

- Views

- 2K

- Replies

- 0

- Views

- 1K

![Craft A Brew - Safale BE-256 Yeast - Fermentis - Belgian Ale Dry Yeast - For Belgian & Strong Ales - Ingredients for Home Brewing - Beer Making Supplies - [3 Pack]](https://m.media-amazon.com/images/I/51bcKEwQmWL._SL500_.jpg)