I know there are several threads similar to this. I have spent hours reading threads trying to identify whats causing my infections. This last batch was my final attempt. I am out of ideas. I will detail my procedure/experiences....

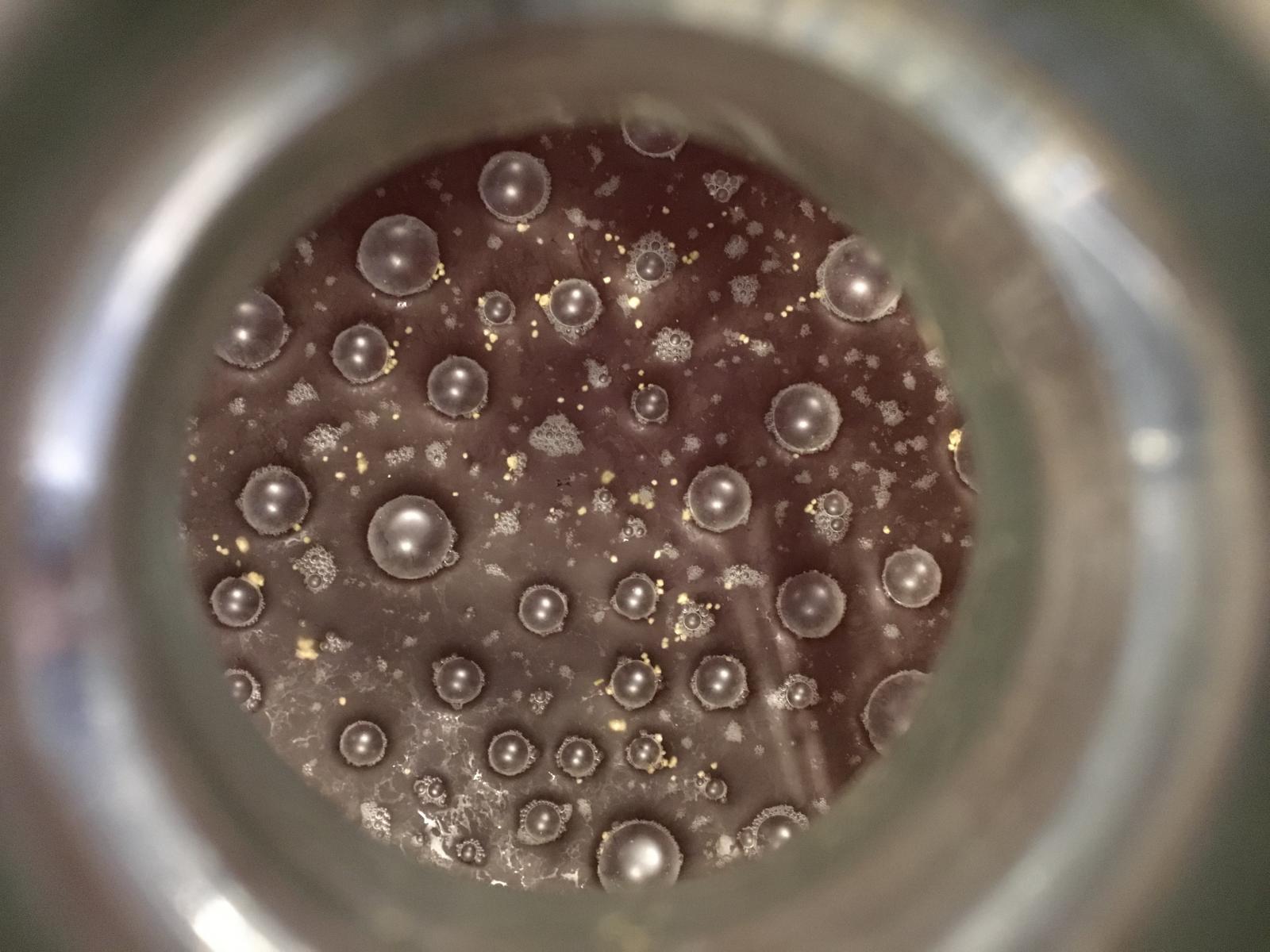

- Have now had 4 infected batches in a row. Fermentation has a normal smell for ~2-3 days and then turns into a vomit smell. FG will be near 1.000, even with S-05. A saison, cream ale, and NEIPA all end up smelling the same awful smell/taste.

- Fermented in existing bucket, glass carboy, and brand new bucket.

- I use starsan on brew day. Make a batch in the fermentation bucket. Soak my spoon, wort chiller, airlock, tubing ( I did not use tubing this past batch and drained straight from kettle to bucket). The bucket/lid gets several shakes and then emptied.

- Brewing in a brand new basement we moved into in November. Had 3-4 good batches before starting to get infection. Have an EBIAB.

- Before last batch, took off ball valve, soaked in oxiclean, and boiled.

- I grind grain in opposite side of basement in a different room

I cannot think of anything else the cooled wort touches on the way to the fermenter. This leads me to something airborne. I do have kombucha fermenting in the same room with just a t-shirt over the jar. What else could I be missing?!

- Have now had 4 infected batches in a row. Fermentation has a normal smell for ~2-3 days and then turns into a vomit smell. FG will be near 1.000, even with S-05. A saison, cream ale, and NEIPA all end up smelling the same awful smell/taste.

- Fermented in existing bucket, glass carboy, and brand new bucket.

- I use starsan on brew day. Make a batch in the fermentation bucket. Soak my spoon, wort chiller, airlock, tubing ( I did not use tubing this past batch and drained straight from kettle to bucket). The bucket/lid gets several shakes and then emptied.

- Brewing in a brand new basement we moved into in November. Had 3-4 good batches before starting to get infection. Have an EBIAB.

- Before last batch, took off ball valve, soaked in oxiclean, and boiled.

- I grind grain in opposite side of basement in a different room

I cannot think of anything else the cooled wort touches on the way to the fermenter. This leads me to something airborne. I do have kombucha fermenting in the same room with just a t-shirt over the jar. What else could I be missing?!

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)