You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Cannot overcome my Hazy IPA oxidation problem!!

- Thread starter tempestam83

- Start date

Help Support Homebrew Talk:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

Did you bottle condition this beer? Yes, there are obviously breweries making this style and getting it to last more then two weeks, but even they don't have nearly the shelf life of a more traditional IPA. The canned NEIPAs usually start to "fall off" around the three week mark (from canning date) in my opinion.

The problem as I see it is the process of bottling and/or bottle conditioning this style of beer in the manner we home brewers usually do. I've made beers of this style where I started with distilled water, added CaCl and gypsum to get to about 140 ppm each of Cl and SO4, used phosphoric acid to get the mash in the 5.3 to 5.4 range and brewed a wonderful beer, only to have that beer turn brown and relatively flavorless after two weeks of bottle conditioning. I have brewed the same beer in the same manner and kegged it instead, and it stays wonderful for a couple months.

It is quite clear to me that O2 exposure is the problem here, and this style is more susceptible than others. Anyone denying that or looking for another explanation is barking up the wrong tree.

Nobody disputes that lots of homebrewers are having O2 issues with the style. The "why" is the real question though.

tgmartin000

Well-Known Member

The brewing network has a near weekly rant on NE ipa's. A few months ago, they went into the shelf stability issues. Tasty's opinion was that these beers have more "spoilage matter" (my term ) in them. More proteins from yeast, things like that, which cause the beers to spoil quicker.

It was one of the session episodes from a few months back. Very interesting conversation, but I can't recall what episode.

It was one of the session episodes from a few months back. Very interesting conversation, but I can't recall what episode.

FruityHops

Well-Known Member

Nobody disputes that lots of homebrewers are having O2 issues with the style. The "why" is the real question though.

I completely agree. Finding out exactly why is the big question.

olotti, what was your malt bill for the DIPA?

It was 2 row, flaked oats and barley, white wheat, c10, carapils and I used 1/2lb of dextrose since I use 1318 in this I find it helps attenuation otherwise even mashing at 150 deg the projected fg is around 1.015-1.016 and since this was a 1.078 og beer I didn't want it to thick or sweet, fg ended up at 1.012.

$20.94

$29.99

The Brew Your Own Big Book of Clone Recipes: Featuring 300 Homebrew Recipes from Your Favorite Breweries

Amazon.com

$176.97

1pc Commercial Keg Manifold 2" Tri Clamp,Ball Lock Tapping Head,Pressure Gauge/Adjustable PRV for Kegging,Fermentation Control

hanhanbaihuoxiaoshoudian

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)

$6.95 ($17.38 / Ounce)

$7.47 ($18.68 / Ounce)

Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]

Hobby Homebrew

$53.24

1pc Hose Barb/MFL 1.5" Tri Clamp to Ball Lock Post Liquid Gas Homebrew Kegging Fermentation Parts Brewer Hardware SUS304(Gas MFL)

Guangshui Weilu You Trading Co., Ltd

$479.00

$559.00

EdgeStar KC1000SS Craft Brew Kegerator for 1/6 Barrel and Cornelius Kegs

Amazon.com

$76.92 ($2,179.04 / Ounce)

Brewing accessories 1.5" Tri Clamp to Ball Lock Post Liquid Gas Homebrew Kegging Fermentation Parts Brewer Hardware SUS304 Brewing accessories(Gas Hose Barb)

chuhanhandianzishangwu

$7.79 ($7.79 / Count)

Craft A Brew - LalBrew Voss™ - Kveik Ale Yeast - For Craft Lagers - Ingredients for Home Brewing - Beer Making Supplies - (1 Pack)

Craft a Brew

$44.99

$49.95

Craft A Brew - Mead Making Kit – Reusable Make Your Own Mead Kit – Yields 1 Gallon of Mead

Craft a Brew

$58.16

HUIZHUGS Brewing Equipment Keg Ball Lock Faucet 30cm Reinforced Silicone Hose Secondary Fermentation Homebrew Kegging Brewing Equipment

xiangshuizhenzhanglingfengshop

$22.00 ($623.23 / Ounce)

AMZLMPKNTW Ball Lock Sample Faucet 30cm Reinforced Silicone Hose Secondary Fermentation Homebrew Kegging joyful

无为中南商贸有限公司

$33.99 ($17.00 / Count)

$41.99 ($21.00 / Count)

2 Pack 1 Gallon Large Fermentation Jars with 3 Airlocks and 2 SCREW Lids(100% Airtight Heavy Duty Lid w Silicone) - Wide Mouth Glass Jars w Scale Mark - Pickle Jars for Sauerkraut, Sourdough Starter

Qianfenie Direct

$49.95 ($0.08 / Fl Oz)

$52.99 ($0.08 / Fl Oz)

Brewer's Best - 1073 - Home Brew Beer Ingredient Kit (5 gallon), (Blueberry Honey Ale) Golden

Amazon.com

$719.00

$799.00

EdgeStar KC2000TWIN Full Size Dual Tap Kegerator & Draft Beer Dispenser - Black

Amazon.com

$53.24

1pc Hose Barb/MFL 1.5" Tri Clamp to Ball Lock Post Liquid Gas Homebrew Kegging Fermentation Parts Brewer Hardware SUS304(Liquid Hose Barb)

yunchengshiyanhuqucuichendianzishangwuyouxiangongsi

JoshStrongarm

New Member

- Joined

- Jan 21, 2016

- Messages

- 4

- Reaction score

- 0

I found this thread after having a couple of NE IPA attempts go dark and manky within a week in the bottle.

I'm of the opinion the yeast is the problem, well some knock on effect of the yeast, probably the lack of flocculation in combination with the hops. I've made 4 recently, 2 with vermont ale/conan, one with WLP644 and one with US-05, as I wanted to see whether the haze was yeast and/or hop level related.

Process and equipment was the same for all and the recipes near identical, with all pale malt, all 0 minute additions only (200gr for 20L) and 200gr for 20L of dry hops. The 644 and US-05 have no issue and both the vermont had gone dark within a week in the bottle.

I'm of the opinion the yeast is the problem, well some knock on effect of the yeast, probably the lack of flocculation in combination with the hops. I've made 4 recently, 2 with vermont ale/conan, one with WLP644 and one with US-05, as I wanted to see whether the haze was yeast and/or hop level related.

Process and equipment was the same for all and the recipes near identical, with all pale malt, all 0 minute additions only (200gr for 20L) and 200gr for 20L of dry hops. The 644 and US-05 have no issue and both the vermont had gone dark within a week in the bottle.

FruityHops

Well-Known Member

I found this thread after having a couple of NE IPA attempts go dark and manky within a week in the bottle.

I'm of the opinion the yeast is the problem, well some knock on effect of the yeast, probably the lack of flocculation in combination with the hops. I've made 4 recently, 2 with vermont ale/conan, one with WLP644 and one with US-05, as I wanted to see whether the haze was yeast and/or hop level related.

Process and equipment was the same for all and the recipes near identical, with all pale malt, all 0 minute additions only (200gr for 20L) and 200gr for 20L of dry hops. The 644 and US-05 have no issue and both the vermont had gone dark within a week in the bottle.

I never made the connection before, but I'm wondering if you might be right. I do recall that the first NEIPA I ever brewed used 1318 and was bottle conditioned. That one never turned brown, but then I tried several batches bottle conditioned with Conan and they all turned brown. That is what caused me to switch to kegs.

Have anybody tried adding antioxidants (SMB, ascorbic acid etc.) at bottling time?

I like the Conan theory, which would indicate biotransformation of the dry hops, or something, not oxygen.

Maybe just something unique it Conan's DNA? In theory, if you leave a can of Heady topper at room temp for a few weeks, it would do the same thing. But, conversely, I bet alchemist has super tight o2 control.

I never made the connection before, but I'm wondering if you might be right. I do recall that the first NEIPA I ever brewed used 1318 and was bottle conditioned. That one never turned brown, but then I tried several batches bottle conditioned with Conan and they all turned brown. That is what caused me to switch to kegs.

I just realized I've done the same thing. I haven't used Conan in prob 6-8 months and prob never will again, I just like what 1318 adds to these beers. I still bottle condition and have never had an issue with oxidation since I switched yeasts. I'm trying one with 007 this week so guess I'll see how this holds up. Wonder what it is with Conan that causes this over other yeasts especially 1318 since that seems to hang in suspension even longer.

Cavpilot2000

Well-Known Member

I just realized I've done the same thing. I haven't used Conan in prob 6-8 months and prob never will again, I just like what 1318 adds to these beers. I still bottle condition and have never had an issue with oxidation since I switched yeasts. I'm trying one with 007 this week so guess I'll see how this holds up. Wonder what it is with Conan that causes this over other yeasts especially 1318 since that seems to hang in suspension even longer.

Maybe it's both oxygen and yeast. Or more specifically, still oxygen, but in theory, if a yeast stayed in suspension longer, it could still be scavenging oxygen longer, and thereby providing anti-oxidative protection for the hops in suspension.

Scturo

Well-Known Member

- Joined

- Jan 31, 2016

- Messages

- 2,553

- Reaction score

- 2,857

I love these hazy IPAs and I've had trouble bottling them too. So now I keg all my IPAs and bottle all my dark beers. No more issues.

But I plan on making a DIPA for a friend of mine and I'm worried about the oxidation factor. I made an IPA last year for a buddy's 40th, which was one of my best (Simcoe, Citra & Mosaic - how could it be bad)... then it oxidized after 6 weeks after bottling! I think I've tightened up my process and technique since then but I'm sweating over the fact that I have to bottle a DIPA for a friend who wants a DIPA, loves DIPAs but doesn't know it could turn after a month or so. Someone unfamiliar to homebrewing doesn't get it and then I sound like I don't want to make it. So I have to conquer this task.

I plan on buying a new auto siphon just in case mine current one has any cracks and I'm going to over fill my 22 oz bottles for min O2 space... I don't cold crash, I have a single keg kegerator. Does anyone else have any tips or tricks they want to share?

But I plan on making a DIPA for a friend of mine and I'm worried about the oxidation factor. I made an IPA last year for a buddy's 40th, which was one of my best (Simcoe, Citra & Mosaic - how could it be bad)... then it oxidized after 6 weeks after bottling! I think I've tightened up my process and technique since then but I'm sweating over the fact that I have to bottle a DIPA for a friend who wants a DIPA, loves DIPAs but doesn't know it could turn after a month or so. Someone unfamiliar to homebrewing doesn't get it and then I sound like I don't want to make it. So I have to conquer this task.

I plan on buying a new auto siphon just in case mine current one has any cracks and I'm going to over fill my 22 oz bottles for min O2 space... I don't cold crash, I have a single keg kegerator. Does anyone else have any tips or tricks they want to share?

duelerx

Well-Known Member

- Joined

- Nov 5, 2015

- Messages

- 258

- Reaction score

- 93

Interesting results thanks for posting!.

Did you bottle condition with carbonation drops or with priming sugar?

Looking forward if we would get the same results using purged bottles with a beer gun and oxygen scavenging caps, or test again using a different yeast.

Scturo

Well-Known Member

- Joined

- Jan 31, 2016

- Messages

- 2,553

- Reaction score

- 2,857

Interesting results thanks for posting!.

Did you bottle condition with carbonation drops or with priming sugar?

Looking forward if we would get the same results using purged bottles with a beer gun and oxygen scavenging caps, or test again using a different yeast.

I used priming sugar to carb the bottles. One thing for sure is that since I've started kegging my beers. They have improved in color and taste. No more astringent after taste.

tempestam83

Well-Known Member

Have anybody tried adding antioxidants (SMB, ascorbic acid etc.) at bottling time?

I started adding half 1/8 tsp of SMB with my priming sugar solution at bottling for three gallon batches. My last batch seemed to last a little longer, but still eventually turned brown.

I bottle and have complained on this thread before about off flavors, perhaps oxidation. I switched to 1318 from Conan and early reports look good. No off flavors so far. This was a partial mash with more extract than usual, I dry hopped 3 times, removing the first two dry hops after a few days. So there were other changes I made that could account for my problem rather than Conan and will take more experimenting... I bet its not leaving hops in too long or the excessive amounts of hops, but either Conan, or in my case, my all grain approach might be leaving me more susceptible to problems as opposed to a more extract heavy batch.

dwankmuller

New Member

- Joined

- May 19, 2017

- Messages

- 3

- Reaction score

- 2

Somewhat new brewer here, but I wanted to share my experience with anyone in case it shed light on this problem. A few weeks ago I brewed a NEIPA (all grain, Wyeast 1318 London Ale III), and split it into two fermenters so I could dry hop them differently and see the result. Since I just started, I'm only brewing 1 gallon batches to get a feel for different ingredients/brewing techniques.

One fermenter was dry hopped once at day 7.

One fermenter was dry dopped twice, once at high krausen, once at day 7.

Out of the fermenter I used a auto-siphon and a spring top bottle filler. (All equipment was cleaned and sanitized with PBW and Starsan) Note that the spring filler cloged up with the NEIPA, so I had some difficulty at the beginning transferring from the fermenter to the bottles. At any rate, I filled my bottles and left about 1" of headspace, added carbonation tablets and capped the beers. I use "EZ-Cap" bottles, so I do not use the typical bottle capper. Bottles were kept in my closet, temperatures in my house did not go above 72F during conditioning.

Since I brew such a small amount, I had a little beer left over from each fermentor, so I combined them and put them in one bottle, that was a little over half full with beer. Note that this bottle was open to the atmosphere the longest, since I added beer from both fermenters. It also probably had the most yeast, since it was the "leftovers" from the end of each fermenter. More on this later...

Since I was excited to try my first NEIPA, I put the bottles of the single hopped NEIPA in the refrigerator after 10 days. I let the bottle chill 24 hours, and opened it the next day. It the beautiful golden NEIPA color that I was going for. (I would post pictures, but havent figured out how to do that yet).

On day 14, I decided to put the rest of the bottles in the refrigerator (including the half filled bottle).

On day 18 I wanted to try the bottle that had a mixture of both beers, so I opened it and the beer was very dark brown/black. It still had a slight hop aroma, but the taste was definitely off. I am not 100% how I would describe it, the bitterness had dulled, but it still tasted like beer, just one that had been sitting around too long.

This made me concerned that the other beer (the beer that was dryhopped 2x) was also ruined. On day 20 I opened the 2x dryhopped beer, and it was the perfect golden NEIPA color as well. Aroma was stronger than the 1x dryhopped beer, and was absolutely delish.

The interesting thing about this, is that I have brewed "normal" IPAs, IBU's in the 50-60 range, with aggressive dryhopping, and filled my conditioning bottle halfway, and have never had a taste/color change.

I read though the entire thread the other night when I opened up my brown beer, and tend to agree that it has something to do with the oxygen in the headspace (in my case, about 1/3 of the bottle was headspace/air) and the interaction with the hop oils and/or yeast that is in suspension in the NEIPA. In my "normal" IPA batches, I used Irish moss, and the yeast settled like a rock.

Feel free to ask questions if anything wasnt clear, just wanted to share my NEIPA experience. I have another batch that I am bottling this weekend, I will not be using my spring filler, since it was such a pain last time, and I will be filling the bottles as close to the top as possible to reduce any possibly oxidation. I will report back in a few weeks...

One fermenter was dry hopped once at day 7.

One fermenter was dry dopped twice, once at high krausen, once at day 7.

Out of the fermenter I used a auto-siphon and a spring top bottle filler. (All equipment was cleaned and sanitized with PBW and Starsan) Note that the spring filler cloged up with the NEIPA, so I had some difficulty at the beginning transferring from the fermenter to the bottles. At any rate, I filled my bottles and left about 1" of headspace, added carbonation tablets and capped the beers. I use "EZ-Cap" bottles, so I do not use the typical bottle capper. Bottles were kept in my closet, temperatures in my house did not go above 72F during conditioning.

Since I brew such a small amount, I had a little beer left over from each fermentor, so I combined them and put them in one bottle, that was a little over half full with beer. Note that this bottle was open to the atmosphere the longest, since I added beer from both fermenters. It also probably had the most yeast, since it was the "leftovers" from the end of each fermenter. More on this later...

Since I was excited to try my first NEIPA, I put the bottles of the single hopped NEIPA in the refrigerator after 10 days. I let the bottle chill 24 hours, and opened it the next day. It the beautiful golden NEIPA color that I was going for. (I would post pictures, but havent figured out how to do that yet).

On day 14, I decided to put the rest of the bottles in the refrigerator (including the half filled bottle).

On day 18 I wanted to try the bottle that had a mixture of both beers, so I opened it and the beer was very dark brown/black. It still had a slight hop aroma, but the taste was definitely off. I am not 100% how I would describe it, the bitterness had dulled, but it still tasted like beer, just one that had been sitting around too long.

This made me concerned that the other beer (the beer that was dryhopped 2x) was also ruined. On day 20 I opened the 2x dryhopped beer, and it was the perfect golden NEIPA color as well. Aroma was stronger than the 1x dryhopped beer, and was absolutely delish.

The interesting thing about this, is that I have brewed "normal" IPAs, IBU's in the 50-60 range, with aggressive dryhopping, and filled my conditioning bottle halfway, and have never had a taste/color change.

I read though the entire thread the other night when I opened up my brown beer, and tend to agree that it has something to do with the oxygen in the headspace (in my case, about 1/3 of the bottle was headspace/air) and the interaction with the hop oils and/or yeast that is in suspension in the NEIPA. In my "normal" IPA batches, I used Irish moss, and the yeast settled like a rock.

Feel free to ask questions if anything wasnt clear, just wanted to share my NEIPA experience. I have another batch that I am bottling this weekend, I will not be using my spring filler, since it was such a pain last time, and I will be filling the bottles as close to the top as possible to reduce any possibly oxidation. I will report back in a few weeks...

One fermenter was dry hopped once at day 7.

One fermenter was dry dopped twice, once at high krausen, once at day 7.

did you hop the same amount in total, or is the 2X beer actually hopped with twice the amount as the other? Also, since it's been a few days, are both beers still holding the flavor and color?

dwankmuller

New Member

- Joined

- May 19, 2017

- Messages

- 3

- Reaction score

- 2

TheHairyHop - The same amount of hops in both (just divided into two additions for the 2x beer).

I bottled my 2nd batch of NEIPA last weekend(5/21). I will place them in the refrigerator after 10 days of bottle conditioning at 70F (5/31). I again had some left over, and was unable to fill a 16oz bottle completely, so there is about ~4 inches of headspace in my bottle (will take photos). Next weekend (6/2) I will open the headspace bottle and see what it looks like.

The rest of the bottles (completely filled) will be opened the weekend of the 6/10. Fingers crossed the flavor/color holds. I will report back, wish me luck.

I bottled my 2nd batch of NEIPA last weekend(5/21). I will place them in the refrigerator after 10 days of bottle conditioning at 70F (5/31). I again had some left over, and was unable to fill a 16oz bottle completely, so there is about ~4 inches of headspace in my bottle (will take photos). Next weekend (6/2) I will open the headspace bottle and see what it looks like.

The rest of the bottles (completely filled) will be opened the weekend of the 6/10. Fingers crossed the flavor/color holds. I will report back, wish me luck.

Another data point -

I think finished beer ph may be playing a role. I has some slight oxidation and darkening in the keg and decided to measure the ph. It was 4.7. I measured as saison in the next keg and it was 4.2. I read up a little and it looks like dry hopping is associated with less of a ph drop in the fermenter. Anyone have some NEIPA sitting around that can take a ph reading. (remember to degas) Higher finished ph is known to make beer much less shelf stable and accelerates darkening. It's also associated with beer not clearing.

For my next batch, I think I'm going to try adjusting the ph down a bit after the kettle.

I think finished beer ph may be playing a role. I has some slight oxidation and darkening in the keg and decided to measure the ph. It was 4.7. I measured as saison in the next keg and it was 4.2. I read up a little and it looks like dry hopping is associated with less of a ph drop in the fermenter. Anyone have some NEIPA sitting around that can take a ph reading. (remember to degas) Higher finished ph is known to make beer much less shelf stable and accelerates darkening. It's also associated with beer not clearing.

For my next batch, I think I'm going to try adjusting the ph down a bit after the kettle.

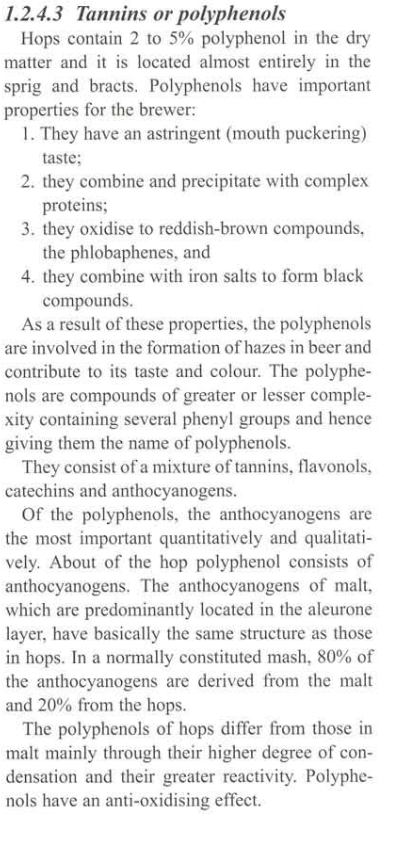

Polyphenol oxidase-enzymatic browning

Care to elaborate?

I've bottled another batch after switching to 1318 from Conan and my off flavor and browning have gone away.

My NEIPA was brewed with WY 1318. Look at the color after 5 Days In the bottle.. Taste/smell cherry-ish. Look and Taste was perfect on bottling Day (picture with the glass).

7oz of dry hop for approx 5G. 5oz at Whirlpool at approx 73F

2 Row

Oats flaked

Dextrine

Oats malted

Cold crashed for 48hrs (but avg temp was 50-55 F)

Used an auto-siphon and bottling bucket.

I've Never checked the PH.. next time i'll try to keep the mash at 5.2

7oz of dry hop for approx 5G. 5oz at Whirlpool at approx 73F

2 Row

Oats flaked

Dextrine

Oats malted

Cold crashed for 48hrs (but avg temp was 50-55 F)

Used an auto-siphon and bottling bucket.

I've Never checked the PH.. next time i'll try to keep the mash at 5.2

Care to elaborate?

I've bottled another batch after switching to 1318 from Conan and my off flavor and browning have gone away.

Excerpt from Technology Brewing and Malting by Wolfgang Kunz

That last sentence confuses the eff out of me

When something gets oxidized, it's effectively an antioxidant with respect to the other, less reactive, chemicals.

Is an oxidized polyphenol still a polyphenol? Point 3 implies otherwise.

If a polyphenol can be oxidized it's awkward to state it's an antioxidant...

Cheers!

If a polyphenol can be oxidized it's awkward to state it's an antioxidant...

Cheers!

Care to elaborate?

I've bottled another batch after switching to 1318 from Conan and my off flavor and browning have gone away.

Polyphenol oxidase (PPO) is the enzyme responsible for turning an apple brown after its cut. It is present in most plant tissue. It requires oxygen and polyphenols to create the browning effect. This reaction takes place much faster than yeast cells can take up the oxygen present in the bottle. While the presence of polyphenol oxidase can be attributed to hops, why don't my heavily hopped San Diego IPAs turn brown? Fungi are prolific producers of this enzyme. Most PO available for research has been isolated from fungi. It will soon be shown that Conan, Vermont etc is a heavy producer. Why doesn't my kegged version get brown. The only way to stop this reaction is low temps, anti oxidants (vitamin C, meta bisulfite) low pH, or low oxygen. kegged versions are cooled immediately. Temps below 40F slow the reaction considerably . Bottle carbonation requires elevated temp. Kimmich fears two things O2 and heat. Mash pH is required to be at the very low end at 5.1 producing a lower pH wort and beer. CO2 push all transfers to remove O2 contamination. 1318 doesn't produce the enzyme in as great amount.

Had to get to my computer. Couldn't type on my phone.

Is an oxidized polyphenol still a polyphenol? Point 3 implies otherwise.

If a polyphenol can be oxidized it's awkward to state it's an antioxidant...

Cheers!

Oxidize just means that something chemically bonds with a free oxygen molecule. The definition of an antioxidant is a compound that oxygen will prefer to bind with and become chemically inert before anything else, thereby preventing it from oxidizing something less desirable. All antioxidants are oxidized to prevent oxygen from being available in solution.

I highly doubt this is a yeast product though. It likely has more to do with the early and massive dry hopping technique causing more of the hop polyphenols to be introduced while there is a higher level of residual oxygen in solution.

Try dry hopping a day later and see if it happens.

Is there actually a flavor change? Or is all this just about the color?

ftea and madking this is great information! Is there a chance that this oxidizing process with Conan also contributes to why Heady Topper is not as hazy as Trillium, Tree House, and Hill Farmstead beers?

ftea and madking this is great information! Is there a chance that this oxidizing process with Conan also contributes to why Heady Topper is not as hazy as Trillium, Tree House, and Hill Farmstead beers?

I really couldn't tell you with any reasonable certainty. It could be any of 100 variables really, but I strongly suspect that a reaction between the massive early dry-hopping, the yeast, and oxygen is causing all of this issue.

My theory is that the yeast is metabolizing some compound present in hops and causing excessive levels of polyphenols to be released/produced which are then oxidized by free oxygen, or even more weakly bound oxygen still in solution, near the beginning of fermentation.

My organic chemistry was never great, so someone with a much higher level of knowledge than me would need to work out if that's even possible. There are likely a number of compounds in hops that could be converted to polyphenols by yeast activity, but I'm just guessing really.

I'm pretty sure that Heady Topper doesn't use Conan anymore in the recipe

Similar threads

- Replies

- 83

- Views

- 2K

- Replies

- 3

- Views

- 283