JunkCatsOnThePorch

Well-Known Member

- Joined

- Jul 11, 2015

- Messages

- 64

- Reaction score

- 6

Ok so I've looked around on here and could only find one person mentioning it once. So Ill ask experienced keggers, as I've been mostly bottle conditioning for a few years.

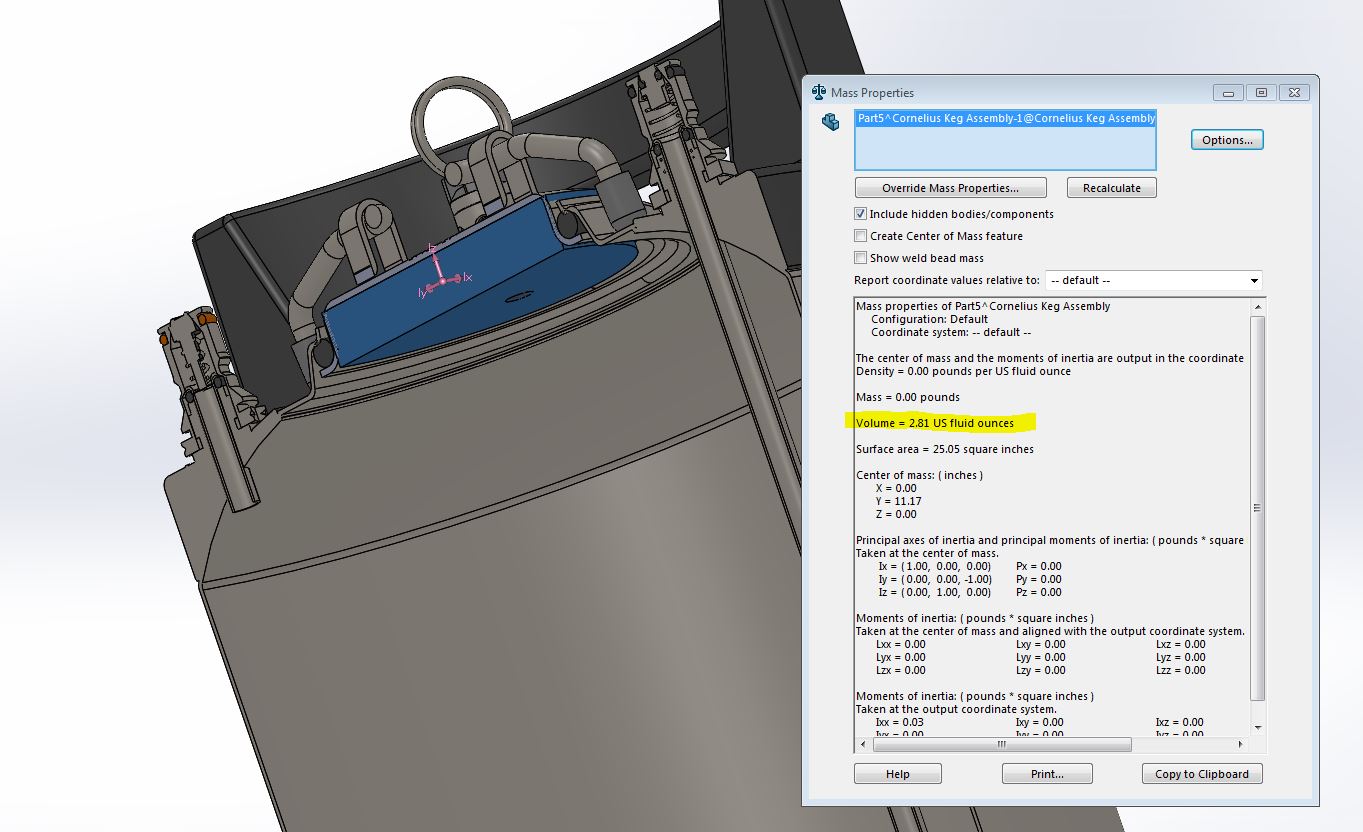

I have heard that if the beer level hits the c02 dip tube, it will not carbonate.

Last time I kegged, I believe it was at or a notch above the 5 gallon mark.

30psi for 3 days did absolutely nothing to it. I pulled off a pint, hit it with 30 psi for 3 days again and got the desired effect.

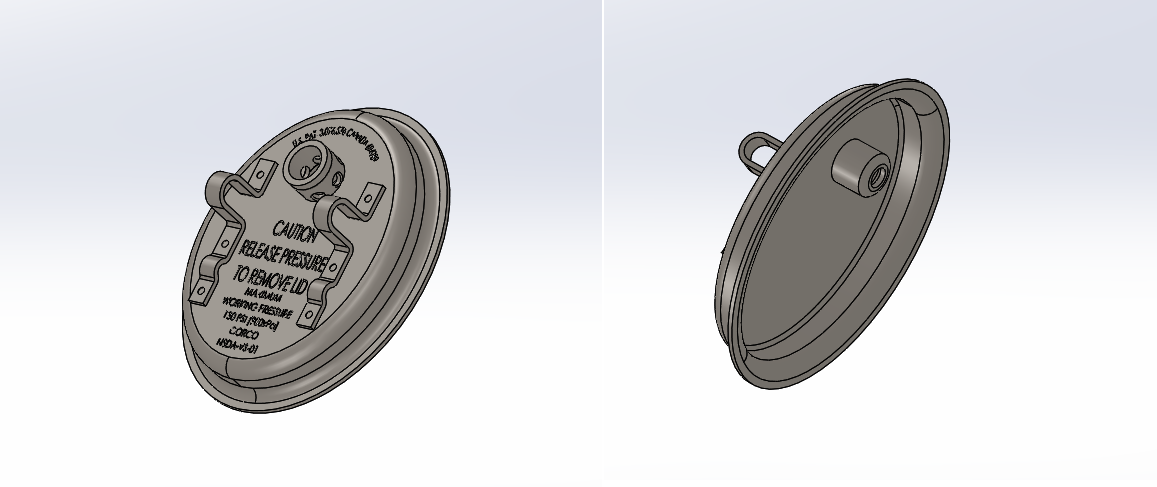

Cant I just cut the dang c02 dip tube a bit? or is it long for a reason? Ive got my keg disassembled with a hack saw ready to go and I am debating.

Standard pin lock keg and the tube is 1 1/4 inches long.

I have heard that if the beer level hits the c02 dip tube, it will not carbonate.

Last time I kegged, I believe it was at or a notch above the 5 gallon mark.

30psi for 3 days did absolutely nothing to it. I pulled off a pint, hit it with 30 psi for 3 days again and got the desired effect.

Cant I just cut the dang c02 dip tube a bit? or is it long for a reason? Ive got my keg disassembled with a hack saw ready to go and I am debating.

Standard pin lock keg and the tube is 1 1/4 inches long.

![Craft A Brew - Safale BE-256 Yeast - Fermentis - Belgian Ale Dry Yeast - For Belgian & Strong Ales - Ingredients for Home Brewing - Beer Making Supplies - [3 Pack]](https://m.media-amazon.com/images/I/51bcKEwQmWL._SL500_.jpg)