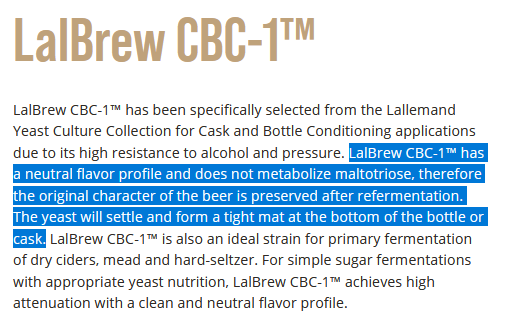

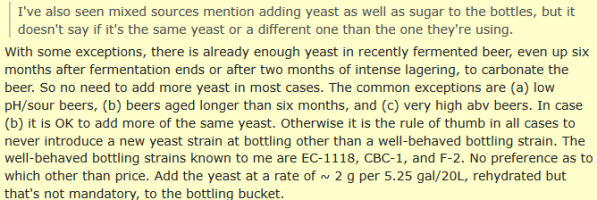

Can I Carbonate with dry yeast?

Normally brewers make yeast starter before bottling with liquid yeast.

But I don't have DME to feed yeast and even If I make the starter, I should carry yeast bottle to the brewing place(I don't brew in my house.)

So I just want to use dry yeast simply distributing yeast in my bottle and add priming sugar and beer.

Is this safe way to carbonate?

I want to listen to some tips, too.

Normally brewers make yeast starter before bottling with liquid yeast.

But I don't have DME to feed yeast and even If I make the starter, I should carry yeast bottle to the brewing place(I don't brew in my house.)

So I just want to use dry yeast simply distributing yeast in my bottle and add priming sugar and beer.

Is this safe way to carbonate?

I want to listen to some tips, too.

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)