Could u send a link to build something like that. I like it vs the false bottom o have that while nice I lose mash efficiency leaving like 2gal under the fb. That looks like it’ll pick up all the wort when u mash. I batch sparge I’m assuming u do to

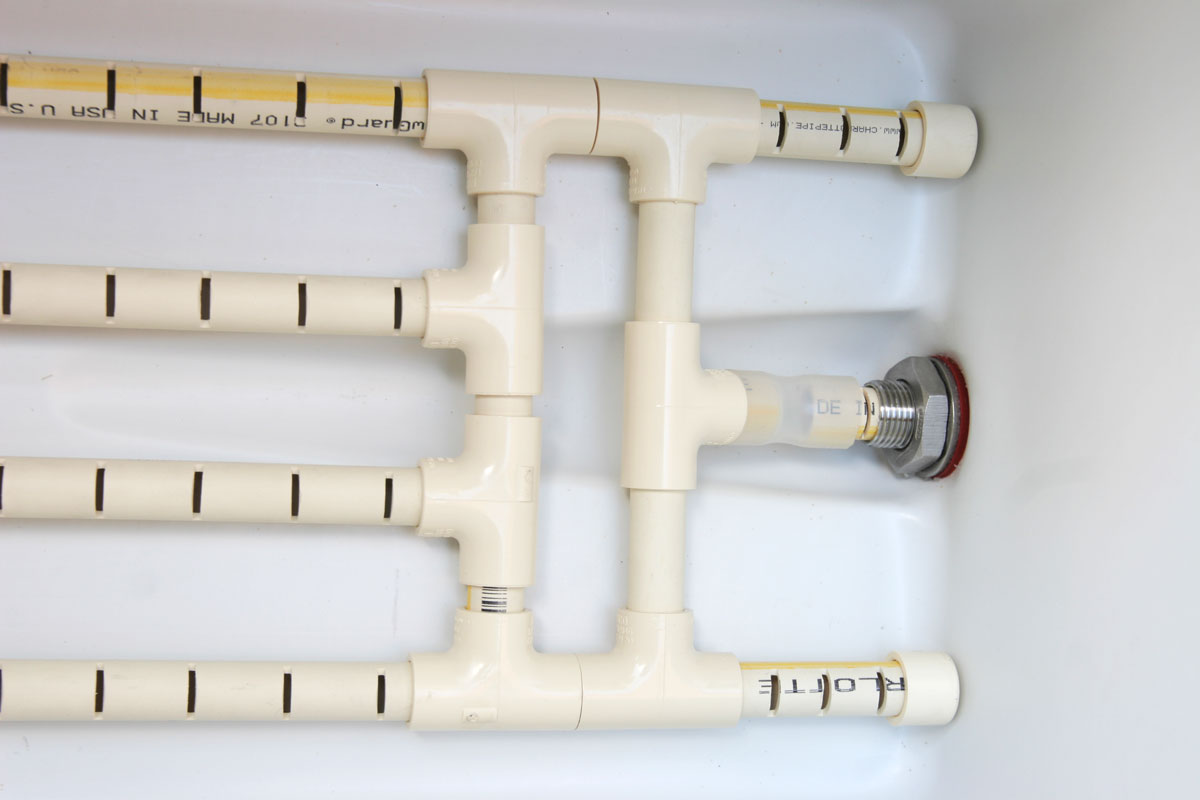

I got this CVPC manifold build and layout from another HBT post, back in 2013. It was for a larger, 70-some qt cooler/tun. I just scaled it down to fit mine. You want those capped ends fit snugly against the walls as those keep it together. It's all friction fit, there's no glue anywhere. I often need to look for the small pieces after dumping it out in the compost bin...

If the tun is larger, having a bit more floor space, the manifold could be improved with another T on each of the 2 outside legs, somewhere in or near that rectangular area where all the Ts connect, to give it a bit more sideways support/clamping power there to the long walls. Although mine has never come apart during the mash, just don't dig it up.

CPVC is really cheap, I think I paid under $10 for a bag of T's, some more (loose) Ts, endcaps and a 10' length of 1/2" CPVC.

Here's the detail of the bulkhead connection area, again, upside down:

I did end up siliconing the bulkhead connection, the flat rubber washer area, because I couldn't get it to seal by itself as the drain hole is not quite perpendicular to the wall.

There's also a plastic "reinforcement tube" siliconed inside the cooler's drain hole, through which the bulkhead runs. That way I can really tighten those nuts down, without squeezing/compressing the cooler wall itself.

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)

(and if it's just the dead space causing your losses, you wouldn't even need to cover the grain bed...if you're worried about to much volume in the BK)

(and if it's just the dead space causing your losses, you wouldn't even need to cover the grain bed...if you're worried about to much volume in the BK)