So I’ve been brewing with my converted round 10gal cooler for 6yrs now but lately I’ve noticed where my false bottom has scratched the sides of the cooler. Didn’t think anything of it till last brew I had a really bad back of tongue astringency that just wouldn’t go away even a month in the keg. initially thought it hop burn or creep so changed my process this time, wp at lower temp with less hops, fermenting cooler mid 60’s but let it free rise to 73 for diacety rest and tonight I took a gravity sample at day 9 and the sample had that same back tongue astringency and this is before the second dh. So when I cleaned my tun last batch I pushed on the bubbled area in my mlt and stanky ass wort came out of a now breach in where the plastic is scratched. I’m wondering if this is doing something with the mash causing this off flavor even after I boil thinking that would kill any bug that may be in the scratches in my mlt.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Can a Cooler mash tun with scratches contribute to an infection

- Thread starter olotti

- Start date

Help Support Homebrew Talk - Beer, Wine, Mead, & Cider Brewing Discussion Forum:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

AJinJacksonville

Well-Known Member

- Joined

- Dec 9, 2016

- Messages

- 684

- Reaction score

- 401

I also use a cooler mash tun, and it has some leftover funk sometimes between brews...even after I clean it out well. That being said, infection of any kind should be a non-issue coming from the mash tun. Like you said, the boil of 60-90 minutes would kill just about anything. I can't imagine that it could affect the taste that much, unless you had a bunch of old stinky wort from a previous batch (like half of your batch's worth).

bubbled area in my mlt and stanky ass wort came out of a now breach in where the plastic is scratched.

that sounds serious, does it taste like insulation?

AJinJacksonville

Well-Known Member

- Joined

- Dec 9, 2016

- Messages

- 684

- Reaction score

- 401

Hahaha...I might have misread that part of it! So it wasn't a scratch per se...it's a breach to the innards of the cooler?

AJinJacksonville

Well-Known Member

- Joined

- Dec 9, 2016

- Messages

- 684

- Reaction score

- 401

I wonder what percentage the alpha acids are at for insulation...haha.that sounds serious, does it taste like insulation?

Time to start batch sparging using a new cooler?

No need for a false bottom and great 80-85% mash efficiency. I've been using a 54 qt rectangular Coleman Xtreme for 7 years, still going as strong as the day I built it.

No need for a false bottom and great 80-85% mash efficiency. I've been using a 54 qt rectangular Coleman Xtreme for 7 years, still going as strong as the day I built it.

AJinJacksonville

Well-Known Member

- Joined

- Dec 9, 2016

- Messages

- 684

- Reaction score

- 401

^^ Exactly what I have...but a toddler cooler (only 4 years old)

No need for a false bottom

going to need something....

AJinJacksonville

Well-Known Member

- Joined

- Dec 9, 2016

- Messages

- 684

- Reaction score

- 401

A true bottom?

for me, no, lol....but i still need stainless braid, or my current bazooka tube......orthwise i'd be making porridge not beer.....

olotti

Well-Known Member

Hahaha...I might have misread that part of it! So it wasn't a scratch per se...it's a breach to the innards of the cooler?

I thought it was just scratching the interior but apparently it breached that and now mash was getting into the interior and god when I pitched in the bubbled scratched part of the cooler prob old wort oozed our and it stunk

AJinJacksonville

Well-Known Member

- Joined

- Dec 9, 2016

- Messages

- 684

- Reaction score

- 401

I'm pretty confident Island has that...or PVC...or copper...

AJinJacksonville

Well-Known Member

- Joined

- Dec 9, 2016

- Messages

- 684

- Reaction score

- 401

Now that that's clear...I'd probably sh*tcan that beer...and the cooler. Yucky!I thought it was just scratching the interior but apparently it breached that and now mash was getting into the interior and god when I pitched in the bubbled scratched part of the cooler prob old wort oozed our and it stunk

olotti

Well-Known Member

I'm pretty confident Island has that...or PVC...or copper...

I'm pretty confident Island has that...or PVC...or copper...

i'm sure he does....but batch sparging has nothing to do with it.....

olotti

Well-Known Member

I’ve also noticed a leak coming between the outer valve of the cooler as it drips down during mash rest and it stinks too like it’s just old mash water pushing out between the valve and the cooler. It smells like the coolers got an infection. Like one would with an abscess.

AJinJacksonville

Well-Known Member

- Joined

- Dec 9, 2016

- Messages

- 684

- Reaction score

- 401

Dude. Put it on the curb. Now...haha.I’ve also noticed a leak coming between the outer valve of the cooler as it drips down during mash rest and it stinks too like it’s just old mash water pushing out between the valve and the cooler. It smells like the coolers got an infection. Like one would with an abscess.

I’ve also noticed a leak coming between the outer valve of the cooler as it drips down during mash rest and it stinks too like it’s just old mash water pushing out between the valve and the cooler.

you gotta take the valve off and clean it once in a while! but sounds like you need a new cooler....

edit personally, i'm used to drinking this type of swill. but most people here have self respect!

AJinJacksonville

Well-Known Member

- Joined

- Dec 9, 2016

- Messages

- 684

- Reaction score

- 401

Yeah...probably the Chinese foam breaking down from the hot wort...barf!!

It’s not hip burn it’s a back tongue vomiting inducing astringency

something like wet dog smell? that's the way my MT smells when i don't dump the grain the same day i brew.....

I'm pretty confident Island has that...or PVC...or copper...

Yup!

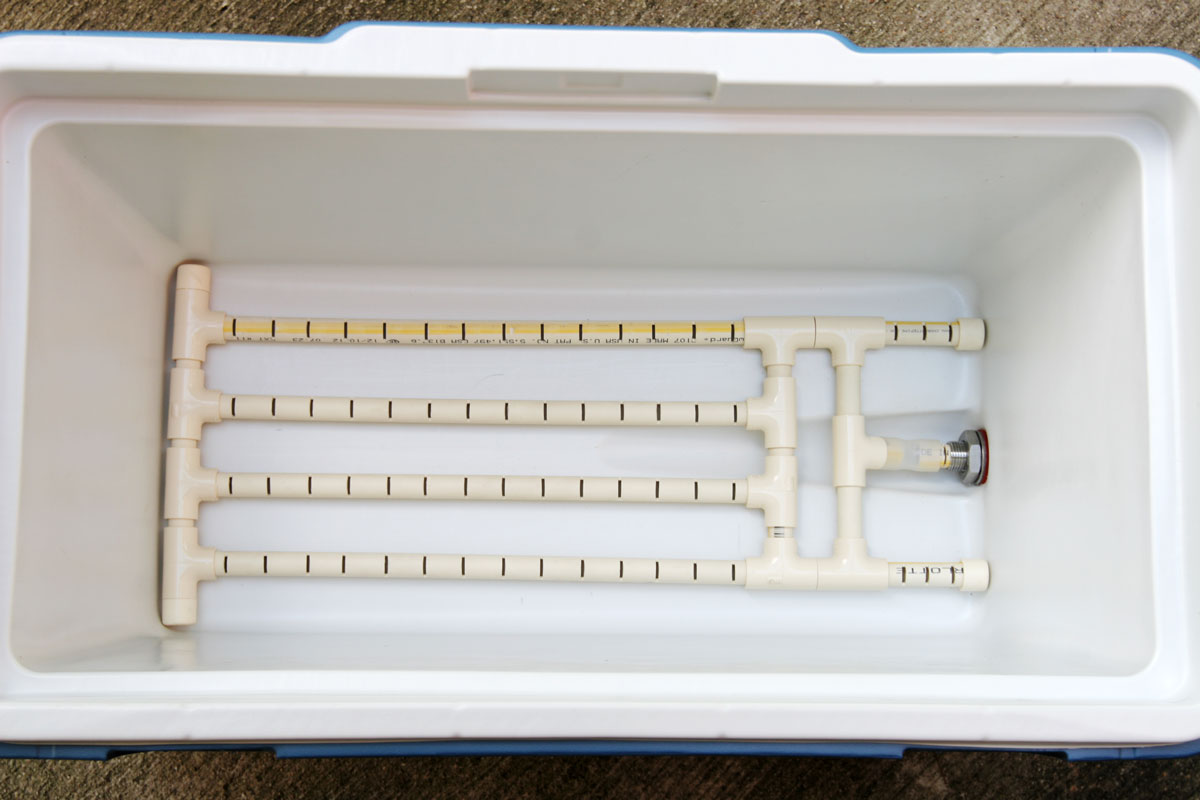

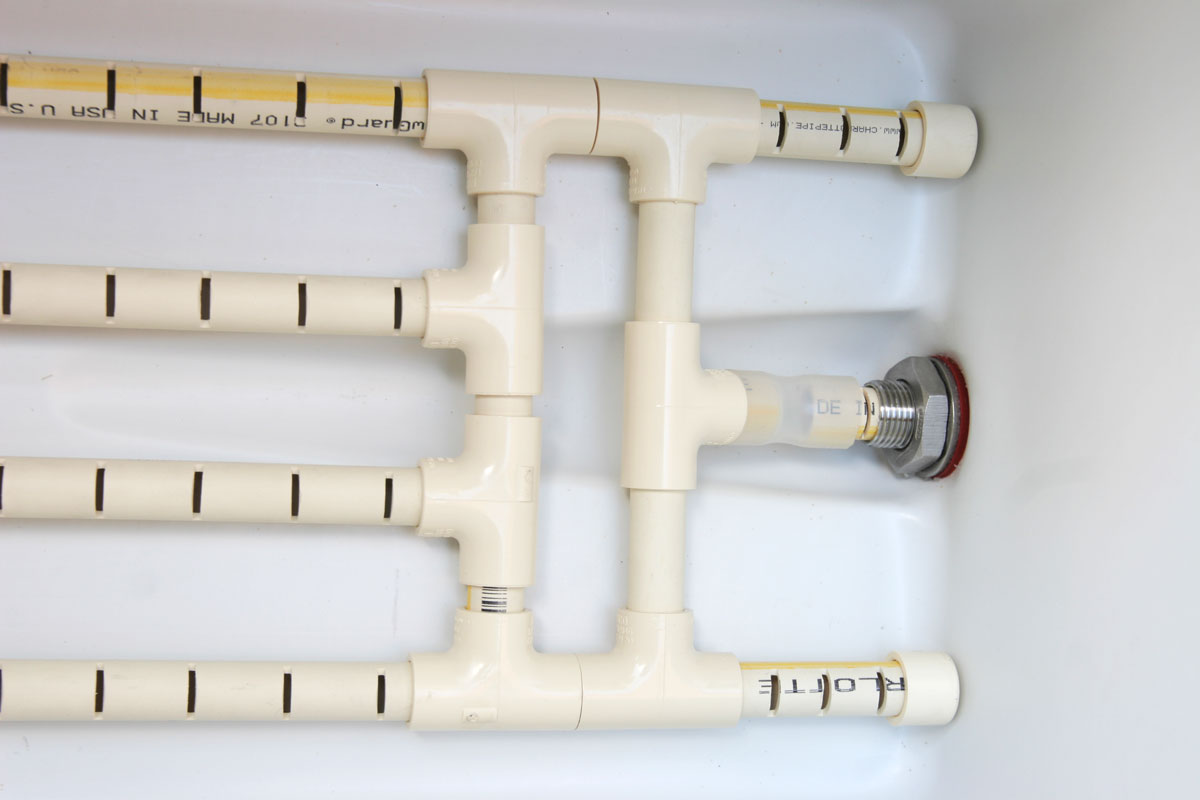

CPVC manifold. Shown upside down.

Everything on the inside has some surface scratches now and has taken on a (light) brown patina.

AJinJacksonville

Well-Known Member

- Joined

- Dec 9, 2016

- Messages

- 684

- Reaction score

- 401

Your post just reminded me that I've got spent grains in my mlt from last week...hahahaha.something like wet dog smell? that's the way my MT smells when i don't dump the grain the same day i brew.....

Dammit man. I got to building rain barrels and refinishing furniture this week...totally forgot.

AJinJacksonville

Well-Known Member

- Joined

- Dec 9, 2016

- Messages

- 684

- Reaction score

- 401

Ya know...I've been thinking about building mine out of PVC...the braided line is starting to show some signs of worn-ness. Did you cut those slots yourself? Do you have some sort of filter before it hits the spigot? Do you like it better than the braided line? More efficient? Trying to come up with some ideas.Yup!

CPVC manifold. Shown upside down.

Everything on the inside has some surface scratches now and has taken on a (light) brown patina.

View attachment 693013

olotti

Well-Known Member

Yup!

CPVC manifold. Shown upside down.

Everything on the inside has some surface scratches now and has taken on a (light) brown patina.

View attachment 693013

Could u send a link to build something like that. I like it vs the false bottom o have that while nice I lose mash efficiency leaving like 2gal under the fb. That looks like it’ll pick up all the wort when u mash. I batch sparge I’m assuming u do to

Not doubting your badly leeching mash tun may have something to do with off flavors or noticeable astringency. But over-sparging or high sparge pH (runoff should remain under pH 5.8) can also cause astringency.[...] till last brew I had a really bad back of tongue astringency [...]

gravity sample at day 9 and the sample had that same back tongue astringency

Maybe your water composition has changed?

And if your brewing water is municipal or otherwise chlorinated, definitely treat all of it with Campden to remove chlorine or chloramines.

something like this great for me....

https://www.morebeer.com/products/kettle-tube-screen-stainless-steel.html

in my round cooler i don't need that much drainage length.....

https://www.morebeer.com/products/kettle-tube-screen-stainless-steel.html

in my round cooler i don't need that much drainage length.....

I used a thin kerf paneling blade on my "table saw" (inverted circular saw), the cuts were very smooth and clean.Ya know...I've been thinking about building mine out of PVC...the braided line is starting to show some signs of worn-ness. Did you cut those slots yourself? Do you have some sort of filter before it hits the spigot? Do you like it better than the braided line? More efficient? Trying to come up with some ideas.

A hack saw blade may be a better choice for making the slots. Or a router.

They're a little less than half way through.

I don't use a filter, just Vorlauf 2-3 times until it runs clear.

The slots could/should be a little narrower than that. Main reason is, I always pick up some grain bits in the first Vorlauf. I Vorlauf about a 1/2 - 3/4 gallon twice (into a 3.5 gallon bucket) before collecting wort for the boil. Sometimes I return the first gallon of the runnings if it's still too cloudy. It's usually fine after that.

The Vorlauf is returned on top of a layer of perforated aluminum foil (ya-ya, I know... maybe I'll use mylar someday) that a) helps keep the heat in during the mash and b) reduces turbulence when returning the Vorlauf since the grain bed (for 5-6 gallon 1.060 batches) is fairly shallow.

Last year picked up another mash tun (came with a deal) that has a braid. I haven't had the opportunity used it yet, so can't compare.

Last year picked up another mash tun (came with a deal) that has a braid. I haven't had the opportunity used it yet, so can't compare

mine lasted a good few years, but ended up getting squished, and not working anymore......

olotti

Well-Known Member

Not doubting your badly leeching mash tun may have something to do with off flavors or noticeable astringency. But over-sparging or high sparge pH (runoff should remain under pH 5.8) can also cause astringency.

Maybe your water composition has changed?

And if your brewing water is municipal or otherwise chlorinated, definitely treat all of it with Campden to remove chlorine or chloramines.

It was a 14lb grist and I mashed in with 7gal distilled water I bought from local grocery store. So I mash in on a 14lb grist with 7 gal then single batch sparge with 4 gal heated to 197 to get the grain bed to 168-170. Let it sit then vorlouf and come t my final running’s. I used to use ro water that you could fill at the stores but those are all shut down but ro and distilled seem to be one in the same. So I use distilled and add my minerals to bru’n water guide to a mash ph of 5.4

Or 5.3

I got this CVPC manifold build and layout from another HBT post, back in 2013. It was for a larger, 70-some qt cooler/tun. I just scaled it down to fit mine. You want those capped ends fit snugly against the walls as those keep it together. It's all friction fit, there's no glue anywhere. I often need to look for the small pieces after dumping it out in the compost bin...Could u send a link to build something like that. I like it vs the false bottom o have that while nice I lose mash efficiency leaving like 2gal under the fb. That looks like it’ll pick up all the wort when u mash. I batch sparge I’m assuming u do to

If the tun is larger, having a bit more floor space, the manifold could be improved with another T on each of the 2 outside legs, somewhere in or near that rectangular area where all the Ts connect, to give it a bit more sideways support/clamping power there to the long walls. Although mine has never come apart during the mash, just don't dig it up.

CPVC is really cheap, I think I paid under $10 for a bag of T's, some more (loose) Ts, endcaps and a 10' length of 1/2" CPVC.

Here's the detail of the bulkhead connection area, again, upside down:

I did end up siliconing the bulkhead connection, the flat rubber washer area, because I couldn't get it to seal by itself as the drain hole is not quite perpendicular to the wall.

There's also a plastic "reinforcement tube" siliconed inside the cooler's drain hole, through which the bulkhead runs. That way I can really tighten those nuts down, without squeezing/compressing the cooler wall itself.

What are you using now?mine lasted a good few years, but ended up getting squished, and not working anymore......

i mill about as fine as the BIAB'rs......

edit: i don't think it'd work for your rectangular cooler though.....fits perfectly in 10 gallon round one though.....

jrgtr42

Well-Known Member

I built something like that for my MLT (48-qt cooler) whenever it was, and it's still running like a champ. I got a length of copper tubing, a handful of connecters, and a tube cutter.

I used my Dremel with a cutoff disk to cut the slots, and a quick sanding just to get the rough edges off.

It's upside down from usual - the slots face down for use. I haven't yet had an issue with parts falling off in use.

I built something like that for my MLT (48-qt cooler) whenever it was, and it's still running like a champ. I got a length of copper tubing, a handful of connecters, and a tube cutter.

I used my Dremel with a cutoff disk to cut the slots, and a quick sanding just to get the rough edges off.

It's upside down from usual - the slots face down for use. I haven't yet had an issue with parts falling off in use.

View attachment 693037

i just gotta ask, why do you guys with the slot ports, always post pics of it upside down?

edit: and damn, i can't even keep my coffee pot as clean as you guy's mash tuns!!!

When buying a new cooler, make sure the drain is flat with the bottom or better yet, recessed into the bottom, or the deadspace might kill you (well, your mash efficiency that is, but when brewing it comes down to almost the same).

Some modern coolers look good, but the drain is 3 inches up from the bottom.

Some modern coolers look good, but the drain is 3 inches up from the bottom.

Similar threads

- Replies

- 13

- Views

- 1K

- Replies

- 4

- Views

- 891

- Replies

- 5

- Views

- 644

- Replies

- 10

- Views

- 547

- Replies

- 5

- Views

- 414