JoeyChopps

Well-Known Member

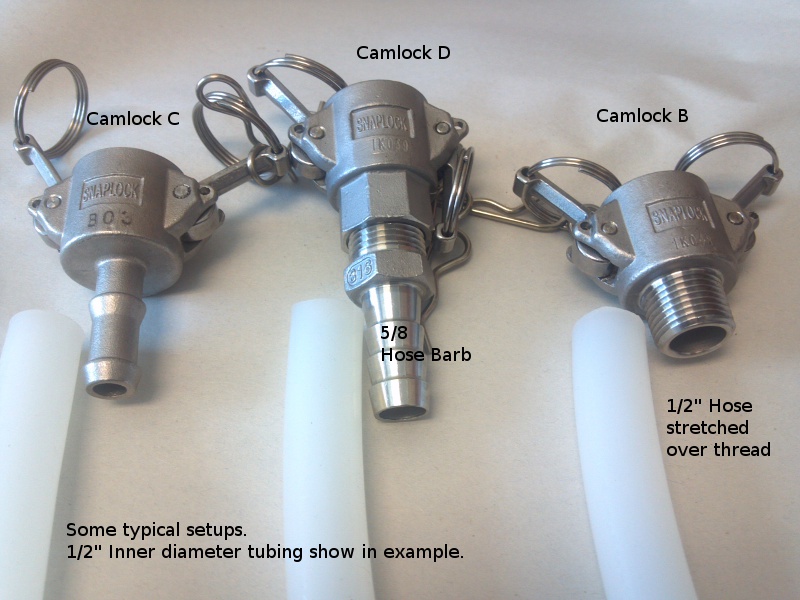

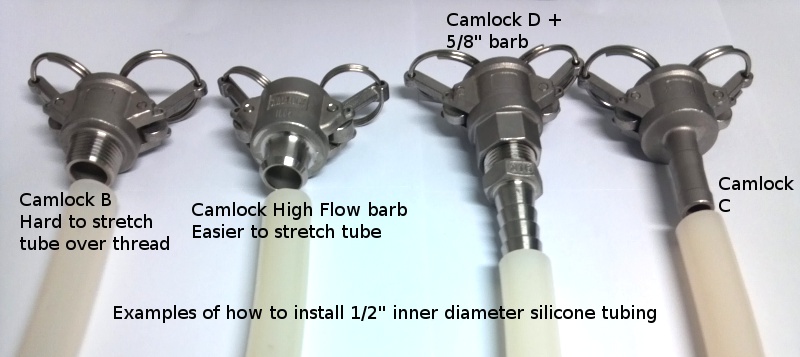

So I got some of the camlocks that are an awesome deal on Austin's . Anyways the opening on the female is smaller than 1/2 in nipple I had on everything. So my question can I drill out the camlock? Are there any issues other than it being hard as hell because its ss?