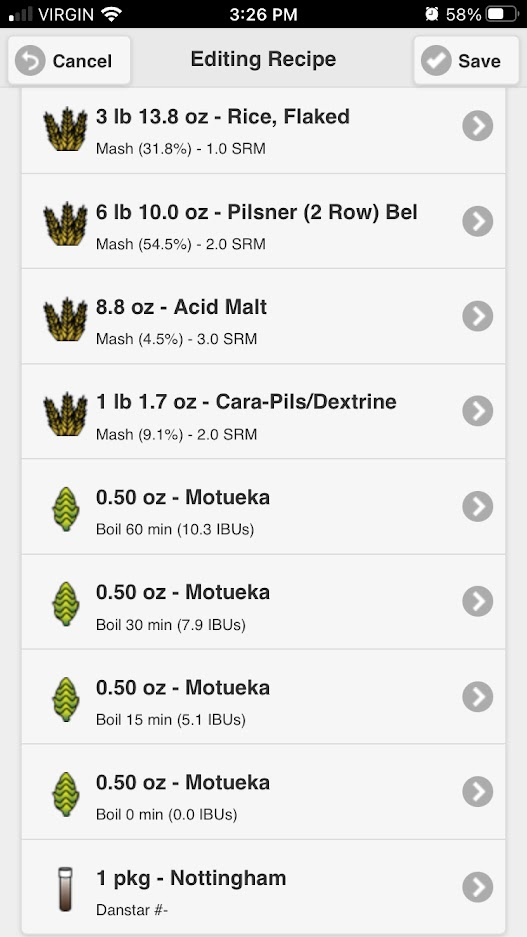

Everything was perfect during the brew day. Tasted when I checked FG and the beer tasted great, minimal O2 exposure. When I went to bottle, I tasted a slight buttery flavor, and a slickness to the tongue. I thought it may be the Motueka hops as it was my first time using it.

Cracked a bottle 1 week into carb to see if the flavor lingered, and I still noticed it.

I kept a temperature of 20C, may dip lower at night, but that was the set temperature.

Any thoughts?

Cracked a bottle 1 week into carb to see if the flavor lingered, and I still noticed it.

I kept a temperature of 20C, may dip lower at night, but that was the set temperature.

Any thoughts?

![Craft A Brew - Safale BE-256 Yeast - Fermentis - Belgian Ale Dry Yeast - For Belgian & Strong Ales - Ingredients for Home Brewing - Beer Making Supplies - [3 Pack]](https://m.media-amazon.com/images/I/51bcKEwQmWL._SL500_.jpg)