First, my theoretical ideal system (since it doesn't really exist)

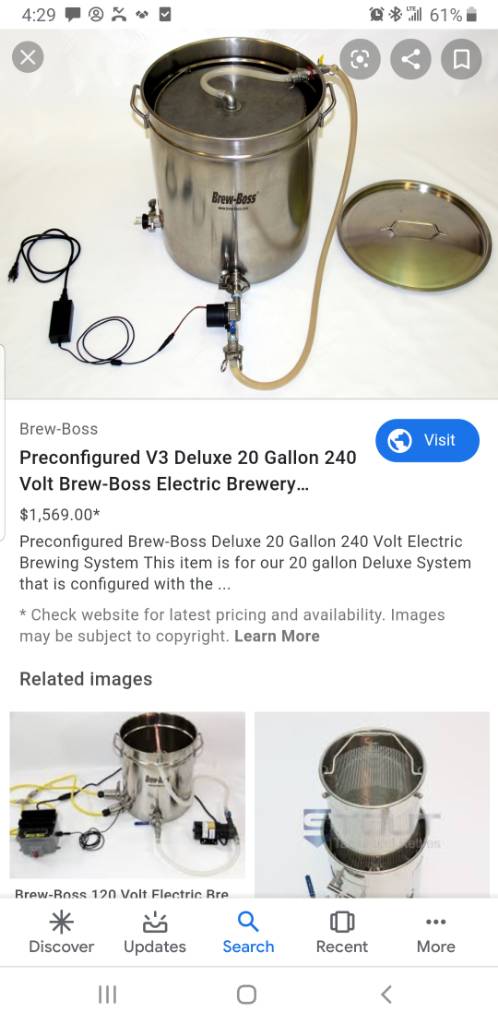

15G kettle with welded fittings for drain, recirculation return and whirlpool & lid with welded fitting for steam slayer

240V induction burner controllable with a PID

SS Basket with minimal deadspace at the bottom

Why I want this:

- 15G kettle is a nice size to do everything from 10G low gravity beers to 5G high gravity stuff.

- Welded fittings because I don't want to deal with potential leaks...I think it's a better solution

- Steam slayer so that I can brew indoors without worrying about ventilation

- Induction burner so that I don't have the large space at the bottom with no grain. With a heating unit in the kettle, it forces longer legs on a basket and intriduces "dead space" below the basket. Recirculation will ensure that wort gets equal contact with the grains, but the dead space imposes limitations for very low and very high gravity brews.

- 240V for fast heating.

- PID compatible for step mashing

- SS basket (vs bag) because I like clear wort.

The issue with this rig is that most induction burners have built in temp settings and, when initially powered up are not heating. Since PIDs work by cycling power, the burner is never in output mode. I've seen one 208v system for overseas that I think people have adapted somehow.

I'd like to see a purpose built induction burner for brewing.

So, take the same concepts and, instead, use a traditional heating coil immersed in the wort. For this I'd go with an SS Brewtech system. I like that their controller works by varying voltage instead of cycling power off/on. It's a welded kettle and the trub dam is pretty cool. They're supposed to come out with a dedicated single vessel brewing system, but they've been saying soon (like next couple months) since last winter.

With that rig, I'd add one other kettle with a false bottom (I'd just use the one I have now) so that I could do kettle rims for really high gravity beers.

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)