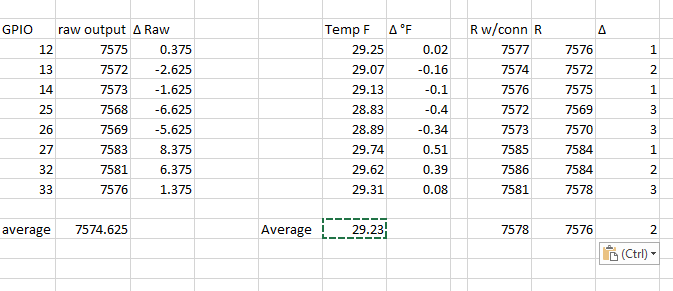

So on the RTD platforms, a few more observations.

1 - The ambient temp of the RTD Amp will raise the raw number about 1 for every increase in degrees F. (I brought a RTD box that was in 95 ambient into conditioned space that was about 80, and the average drop in the raw number was 13)

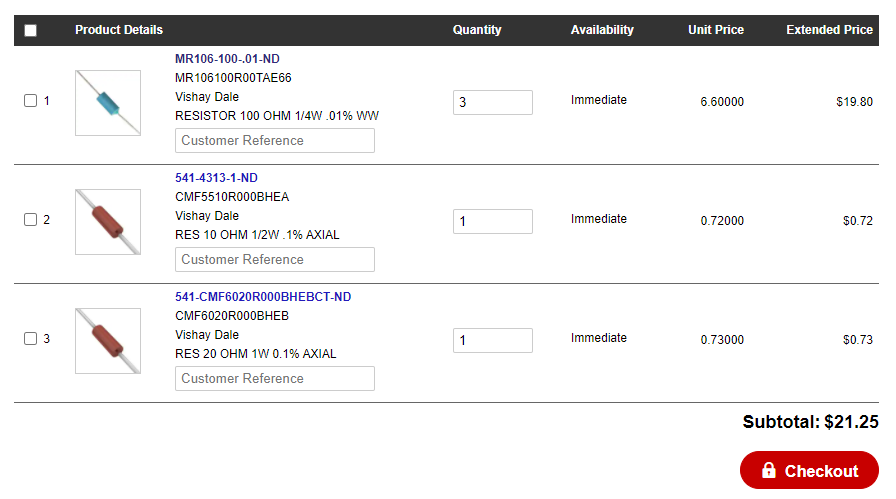

2 - Batches of RTD Amps seem to have more effect than the brand(assumed this before, but with 16, I can say it is true.. I suggest buying double what you ever think you will need from the same vendor (I got 8 for $24.66 from " All Electronics Trading Company " on aliexpress, and just ordered 8 more, hoping I get same batch). Previously, I ordered 2 Adafruit ones (12/2017) and 6 aliexpress (8/2019 same seller as above!), and they are all over the board. the std dev is *horrible*, just scratching my head... the 8 I just bought are fantastic in comparsion.

3 - I don't know if 4-wire RTD will have this same issue, I think it will, I do not know if thermistor boards will have this same issue, but I know that 1-wire will not, it is physically impossible... I would LOVE if they added a couple extra bits to the DS18B20, I know we could add 1 bit at the expense of speed, but the DS18B20 has been around at least since 1998, someone has to have made a 14-16bit 1-wire temp sensor...

4 - I will probably limit RTD to the few places I really need tenth-of-a-degree resolution, and return to 1-wire wherever possible, hoping that statically assigned addresses is implemented for 1-wire.

(chart is resistor plugs only, no actual probes.)

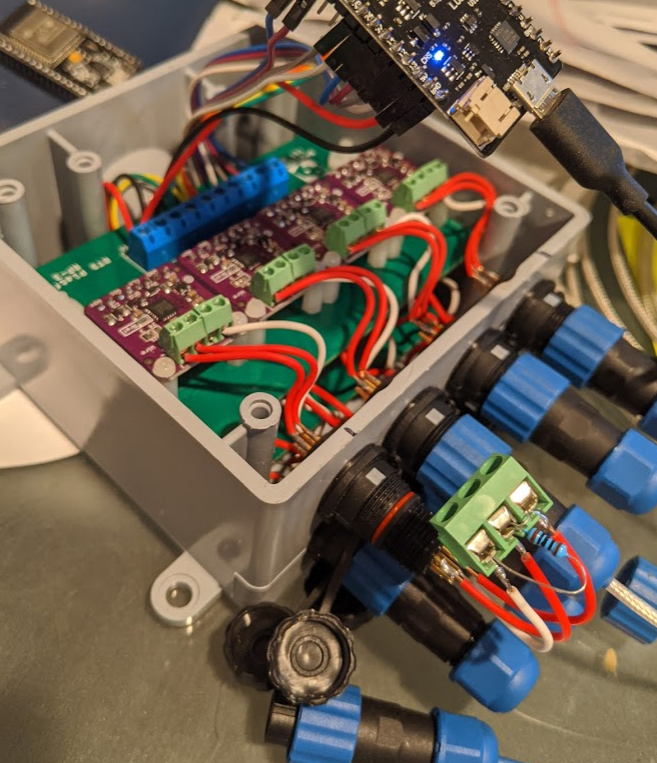

View attachment 701576

![Craft A Brew - Safale BE-256 Yeast - Fermentis - Belgian Ale Dry Yeast - For Belgian & Strong Ales - Ingredients for Home Brewing - Beer Making Supplies - [3 Pack]](https://m.media-amazon.com/images/I/51bcKEwQmWL._SL500_.jpg)