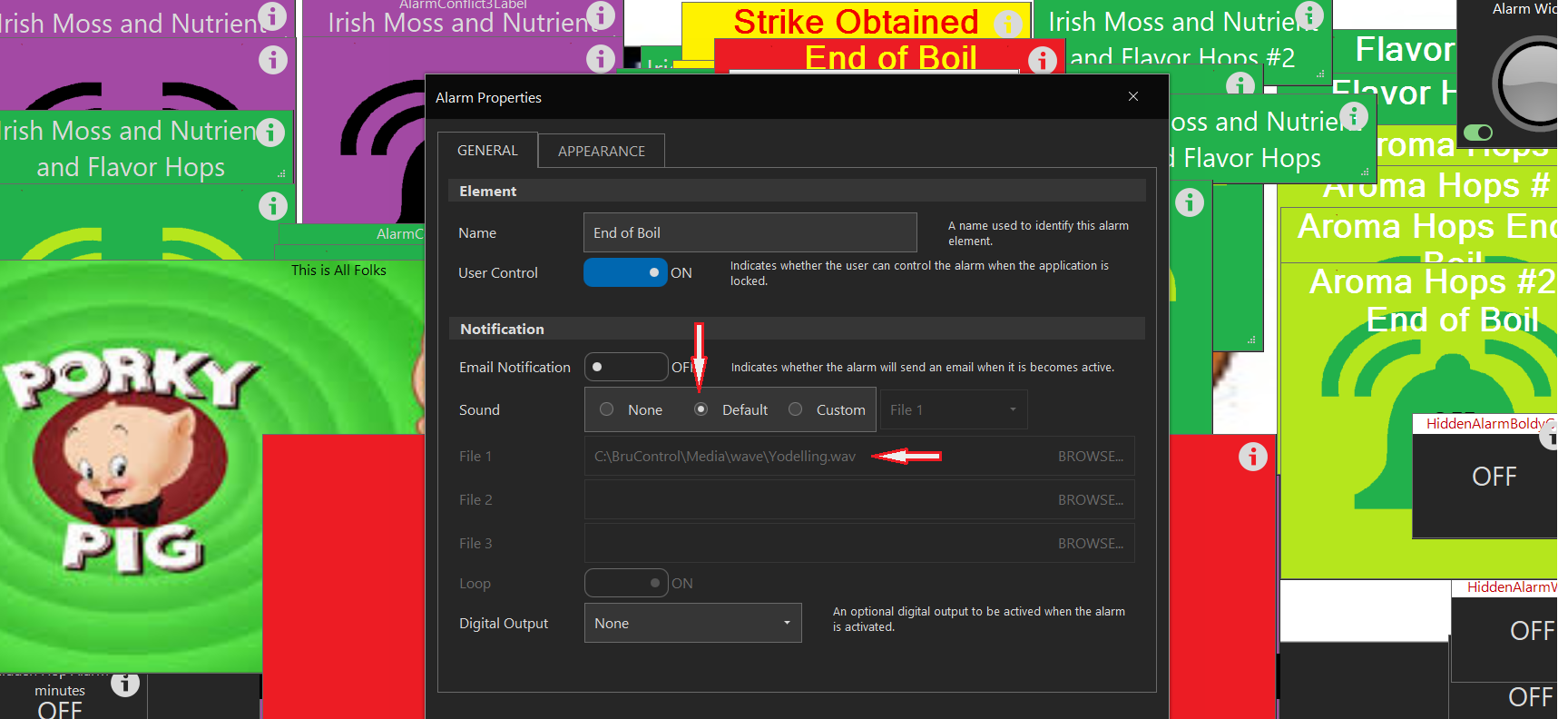

In Build 9, All of my Alarms are there and the wav file path is in the File 1 slot, but the radio button is set to "Default" causing the the alarm to be "Ding Dong" default sound rather than the selected file. An End User needs to go to each Alarm and set the Radio Button to "Custom" to have the Program play the custom file.

I have an Alarm Workspace with 30 Stacked Alarms, all with a unique wav file. I use "Text to Speech" to create the custom alarms for the most part. Since they are stacked, it will be a pain to do that and then re stack them. Since I can have only 3 choices of Alarm and Graphic, and the new Alias, I can likely reduce the number of Alarms to 11 or 12, or maybe even 10.

If I had a Script Command like "wavpath1" that allowed me to change the string value of Sound File 1 for the Alarm Sound, and another Script Command like "backpath1" that allowed me to change the background Image 1, it would allow me to move the alarms to my main Switchboard and get rid of my "Alarm" Workspace as I could have One or Two Alarms.

Example where I could have a single Alarm Element. It would certainly make it much easier for me.

"MyAlarm" wavpath1 = "C:\BruControl\Media\Wav\FlavorHop.wav"

"MyAlarm" backpath1 = "C:\BruControl\Media\Image\FlavorHop.jpg"

"MyAlarm" displayname = "Drop Flavor Hops"

"MyAlarm" active = True

Since I can have unlimited displaynames, I am reducing the number of Timers.

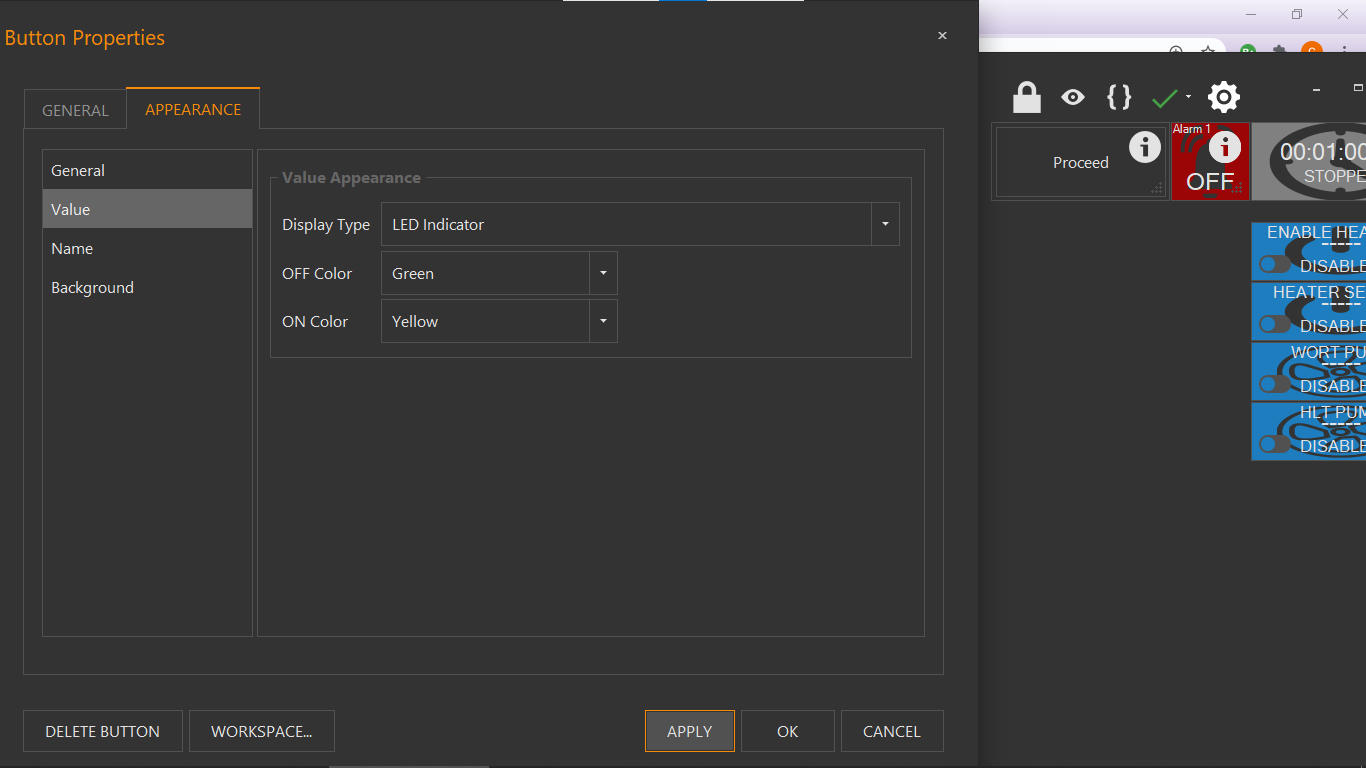

View attachment 689507

![Craft A Brew - Safale BE-256 Yeast - Fermentis - Belgian Ale Dry Yeast - For Belgian & Strong Ales - Ingredients for Home Brewing - Beer Making Supplies - [3 Pack]](https://m.media-amazon.com/images/I/51bcKEwQmWL._SL500_.jpg)