Couple more questions:

1.) What is the "Integrated I/O" option when purchasing the Uniflex?

2.) What are the minimum computer requirements for BruControl? OS/Processor/RAM

3.) Does the Uniflex Dual Vessel Option control one vessel at a time? How is the active vessel output selected? A GUI element or a script variable, etc...?

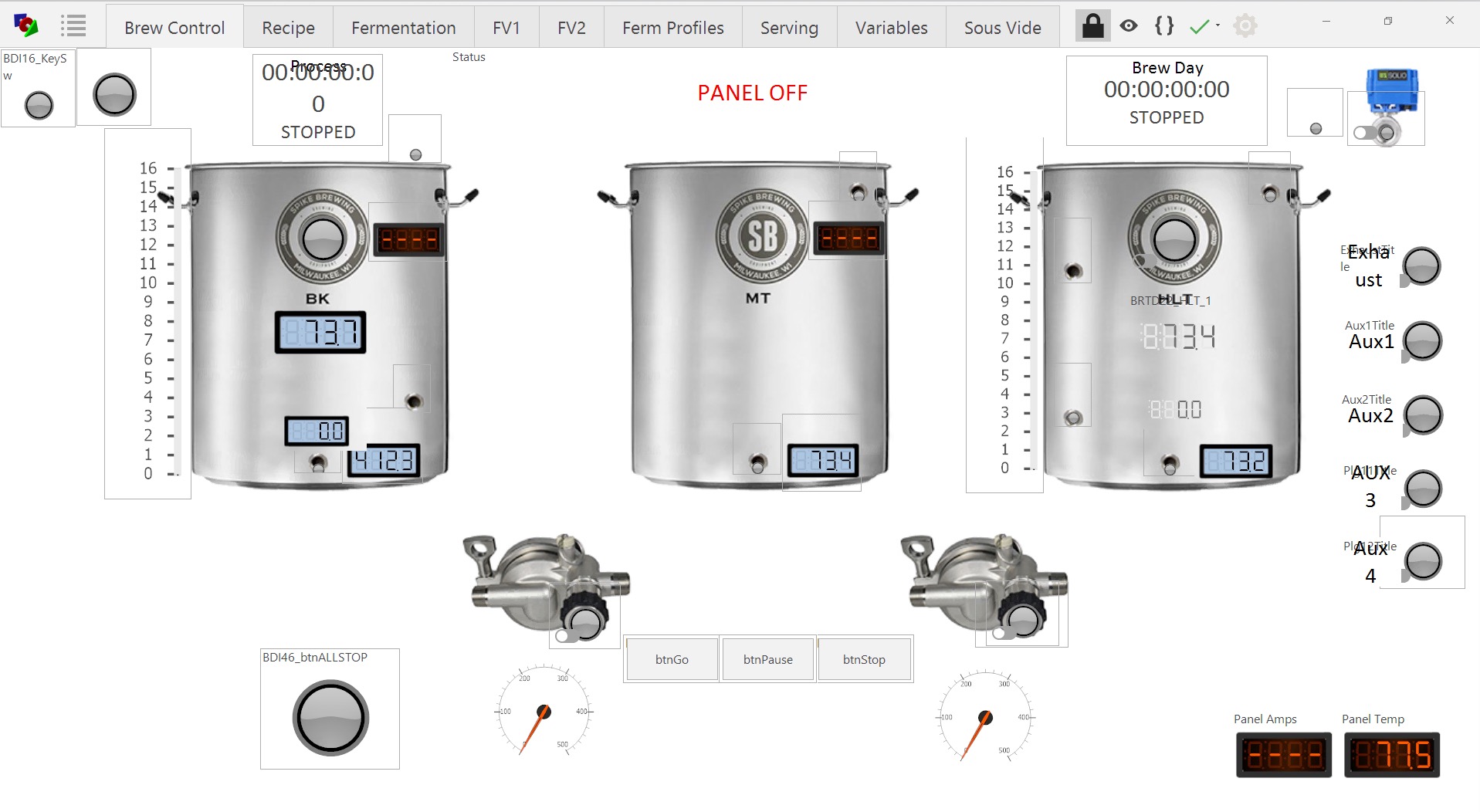

Took an hour and made a test - multi-step mash interface but haven't really pursued anything beyond this.

A couple things I've noticed is the laggy interface and intermittent "lock-up" or stalling of the script at times. Perhaps I need to upgrade to Win10 (as BruControl appears to written against WPF vs. WinForms) and get actual hardware, like a PID or the Uniflex, etc... The scripting language takes a bit to get used and isn't as "full blown" as a normal programming language but the manual helps some. Being able to lasso multiple controls and move then in a group would be useful (more accustom to the Visual Studio editor). Documentation could be a bit more expansive but most things can be learned or gathered from what's available. All in all I can envision creating a dual vessel BIABasket system with this.

View attachment 686762

Code:

[initialize mash]

new value sound_alarm 0

new value mash_temperature 0

new time t 00:00:00:00

new bool MT1 false

new bool MT2 false

new bool MT3 false

new bool MT4 false

new bool MT5 false

new bool MT6 false

new time MT1T 00:00:00:00

MT1T = "Mash Timer 1" value

new time MT2T 00:00:00:00

MT2T = "Mash Timer 2" value

new time MT3T 00:00:00:00

MT3T = "Mash Timer 3" value

new time MT4T 00:00:00:00

MT4T = "Mash Timer 4" value

new time MT5T 00:00:00:00

MT5T = "Mash Timer 5" value

new time MT6T 00:00:00:00

MT6T = "Mash Timer 6" value

[mash]

if "Mash Timer 1" value > t

MT1 = true

mash_temperature = "Mash Temperature 1" value

start "Mash Timer 1"

else

if "Mash Timer 2" value > t

MT2 = true

mash_temperature = "Mash Temperature 2" value

start "Mash Timer 2"

else

if "Mash Timer 3" value > t

MT3 = true

mash_temperature = "Mash Temperature 3" value

start "Mash Timer 3"

else

if "Mash Timer 4" value > t

MT4 = true

mash_temperature = "Mash Temperature 4" value

start "Mash Timer 4"

else

if "Mash Timer 5" value > t

MT5 = true

mash_temperature = "Mash Temperature 5" value

start "Mash Timer 5"

else

if "Mash Timer 6" value > t

MT6 = true

mash_temperature = "Mash Temperature 6" value

start "Mash Timer 6"

endif

endif

endif

endif

endif

endif

if MT1 == true

if "Mash Timer 1" value <= t

MT1 = false

stop "Mash Timer 1"

if MT1T > 00:00:00:00

sound_alarm = 5

"Mash Alarm" Active = true

endif

endif

endif

if MT2 == true

if "Mash Timer 2" value <= t

MT2 = false

stop "Mash Timer 2"

if MT2T > 00:00:00:00

sound_alarm = 5

"Mash Alarm" Active = true

endif

endif

endif

if MT3 == true

if "Mash Timer 3" value <= t

MT3 = false

stop "Mash Timer 3"

if MT3T > 00:00:00:00

sound_alarm = 5

"Mash Alarm" Active = true

endif

endif

endif

if MT4 == true

if "Mash Timer 4" value <= t

MT4 = false

stop "Mash Timer 4"

if MT4T > 00:00:00:00

sound_alarm = 5

"Mash Alarm" Active = true

endif

endif

endif

if MT5 == true

if "Mash Timer 5" value <= t

MT5 = false

stop "Mash Timer 5"

if MT5T > 00:00:00:00

sound_alarm = 5

"Mash Alarm" Active = true

endif

endif

endif

if MT6 == true

if "Mash Timer 6" value <= t

MT6 = false

stop "Mash Timer 6"

if MT6T > 00:00:00:00

sound_alarm = 5

"Mash Alarm" Active = true

endif

endif

endif

print mash_temperature

// set PID target to mash_temperature here

sleep 1000

sound_alarm -= 1

if sound_alarm < 0

"Mash Alarm" Active = false

sound_alarm = 0

if MT1 == false

if MT2 == false

if MT3 == false

if MT4 == false

if MT5 == false

if MT6 == false

reset "Mash Timer 1"

reset "Mash Timer 2"

reset "Mash Timer 3"

reset "Mash Timer 4"

reset "Mash Timer 5"

reset "Mash Timer 6"

stop "Mash Control"

endif

endif

endif

endif

endif

endif

endif

goto "mash"

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)