DoubleHaulBrewing

Well-Known Member

Understood. Thank you for that.

So, I'm tackling the data exchange design on my build and have the basic hang of it using Node-Red and watching Bryan's Youtube several times. I'm having trouble with time. BeerSmith seems to use minutes for it's time related values. I'm looking for help getting the change node (Beer Parameters node in Bryan's example) properly formatted for acceptance into BruControl. If anyone has tackled this I would love some suggestions.

Thanks,

Mike

if(msg.BoilTime < 60){BoilTime = "00:"+msg.BoilTime}

if(msg.BoilTime >= 60){

msg.remainder = msg.BoilTime - 60

BoilTime = "01:"+msg.remainder

}BoilHrs = 0;

BoilTime = msg.BoilTime;

while(BoilTime >= 60){

BoilTime -= 60;

BoilHrs ++;

}

BoilTime = BoilHrs + ":" + BoilTime;

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)

@Die_Beerery what software are you using to create your backgrounds, they look great!Initial look at the dual-vessel Workspace for the UniFlex. Need to add an alarm and maybe an I/O bank... plus the colors are a little cartoony but it needs to be clear and easy, so this is basic start. Suggestions appreciated!

We would provide to users to get started, then they can modify as they see fit. Sincere thanks to @DieDie_Beerery_Beerery for the background graphic!

View attachment 683402!

PostBoilVolume = (BatchSize+KettleLoss)*1.04

PreBoilGravity = (((((PostBoilGravity-1)*1000)*(BatchSize+KettleLoss))/BoilVolume)/1000)+1What's that magic factor '1.04' ? Spillage? Samples? Quarts to liters?Correct, for some reason it is not part of the BeerXML standard, so we have to calculate it based on other data that is included.

In the function block, add these two lines.

Code:PostBoilVolume = (BatchSize+KettleLoss)*1.04 PreBoilGravity = (((((PostBoilGravity-1)*1000)*(BatchSize+KettleLoss))/BoilVolume)/1000)+1

Obviously, make sure you are bringing in PostBoilGravity, BatchSize, KettleLoss and BoilVolume from the BeerXML.

Cheers,

Joe

Question on AREF, if I am going to power the TF-4 with a separate 5VDC supply, should AREF be tied to that supply rather than the 5V pin on the MEGA?

Thanks

My experience with the RTD amplifier boards is similar to @clearwaterbrewer in the fact that I suspect SPI bus or general chip power issues can also cause these spikes. I built a panel to use 4 amplifier boards and soldered up some headers on a perf board to mount the amplifier boards. I also had a local LCD display on this panel. When I powered all the 5V components from the mega's onboard LDO I would get similar temp spikes when I enabled and wrote to the display. I got similar spikes when one of my fridges would turn on/off in the garage. I changed the power for the amplifiers to a separate 5V supply and that fixed the LCD issue, but not the fridge spikes.

My main brew panel that is also mounted in my garage does not have any of these issues, but I use thermistors in that panel. I have found that as long as you use a 1% or better 10K reference resistor and some caps for filtering that thermistors are accurate within their 1% specification without having to individually calibrate each sensor/circuit. The biggest bitch is calculating the steinheart coefficients, but I found a small script in the interwebs that will calculate those for you from the resistance/temp table in the thermistor's datasheet.

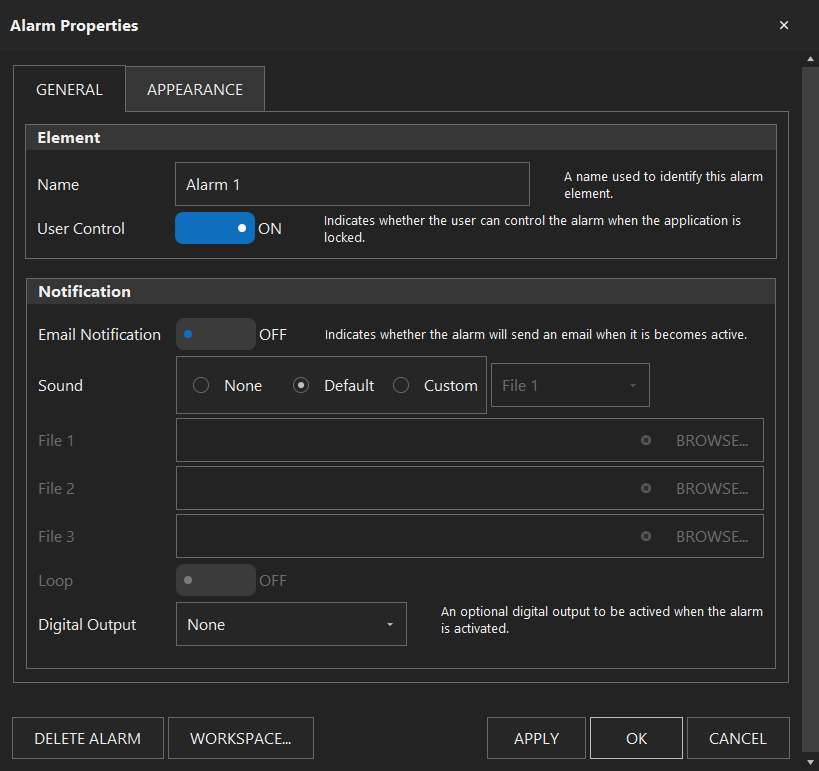

Looks great. Would still be great to have a Path that could be a script property:

It would make the program much better if you had unlimited sound or image files via a local path rather than the three limit. You would only need to add the script property for File1 or Background1.

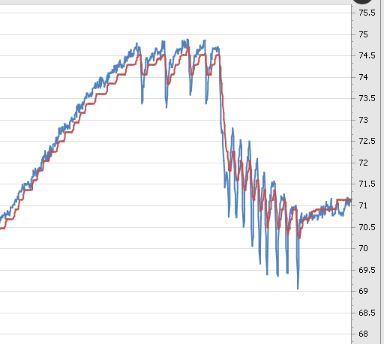

Here's a screen grab of my NTC and 1-wire sitting side-by-side......NTC is blue:While I am least a year away, I think it is start to plan. Since I am starting fresh, any comments on best temperature probes.

BCS 10K NTC Type

RTD 100

RTD 1000

One Wire

Pros and Cons:

I have been following the discussions regarding the RTD amps.

What type of sensor was this and what did you end up with for Kp, Ki, and Kd?While we are sharing graphs,I had to post this... doing a video for the UniFlex, I set up a test bed using a 5500W heater in a small vessel, with no recirculation. I noticed an interesting oscillation develop when using default PID parameters. This was likely due to a lag that occurred between the heated, rising water reaching the probe mid-vessel. Did some manual tuning, and after about 5 iterations dialed it in quite a bit. This required lowering the Kp and integral windup (Max Integral %), and increasing the Kd quite a bit.

I know there have been requests for auto-tuning, but since 1. we aren't flying aircraft or rockets, and 2. we have brains... my feeling is we should be able to manually tune most brewing applications. I'm going to try a deadband on this and see what happens.

View attachment 685778

While I am least a year away, I think it is start to plan. Since I am starting fresh, any comments on best temperature probes.

BCS 10K NTC Type

RTD 100

RTD 1000

One Wire

Pros and Cons:

I have been following the discussions regarding the RTD amps.

........

I can say that if they made a 1-wire with the resolution of the RTD, at a cost of less than double of a DS18B20, that worked with BruControl, I would throw all my sensors in the damn trash and completely switch out...... it looks like post 3989 says BruControl uses 11 bit on the 1-wire, whereas 12 bit is what my ESP32/MAX31865/RTD has I guess, so maybe it is good enough... I thought the difference was at least 2 bits.. how much overhead would giving the option for 12 bit give?

RTD's -

Pros: accurate

Cons: They are not (cannot be) calibrated from the factory, calibrating BruControl to them is more difficult that it seems like it should be. They have downward spikes that makes triggering difficult without writing intermediary scripts.

1-Wire -

Pros: Easy to implement multiple proves without additional hardware

Cons: Not accurate enough and lack address permanence and manual designation in BruControl.

Tilt Hydrometer:

Pros: work great inside a fermenter

Cons: The resolution is horrible and only does 1.0 degrees F. BruControl implementation is painfully slower than the Tilt App or TiltPi program that reads every second. BruControl has no method to smooth out erroneous readings, ideally, it would read and display the user's choice of either the instantaneous reading or the average of the last 10 readings, and graph every 15 minutes to save datapoint memory.

I can say that if they made a 1-wire with the resolution of the RTD, at a cost of less than double of a DS18B20, that worked with BruControl, I would throw all my sensors in the damn trash and completely switch out...... it looks like post 3989 says BruControl uses 11 bit on the 1-wire, whereas 12 bit is what my ESP32/MAX31865/RTD has I guess, so maybe it is good enough... I thought the difference was at least 2 bits.. how much overhead would giving the option for 12 bit give?

From what I understand it is the first bit that is dropped for 11-bit resolution.....that is the 2^-4 bit. Accuracy is +- 0.5C (0.9F) so it doesn't seem that resolving out to -4 vs -3 would make much difference. Our critical temperature measurement is mash temp in brewing so I guess the question is, is +- 0.9F accurate enough?

RTD's are around 0.1C (0.2F) and I guess the challenge is to properly calibrate it so the precision is correct.

A 1% NTC provides +- 0.5C from 0 - 40 and +- 1.0 from -40 to 80. So in the mash temp range, NTC's are probably the least desirable.

no, I have not looked at lookup tables... manually editing tens or hundreds of values for each thermometer probe sounds daunting...Not sure what you mean calibrating is more difficult than they should be? Have you ever used the Lookup Table? Also spikes are a hardware problem - these are collections of noise that the builder needs to manage/suppress. We are building in some aberrant rejection - this isn't as easy as it sounds, because legacy reads need to be maintained. Stay tuned on this, but in the meantime, address any hardware issues. We've discussed 1W addresssing and will add it at some point. You are correct that we need to fix the error readings on the Tilt!

Gotta remember that 1W sits in the middle of the good/fast/cheap triangle - you can't have all three. We picked 11 bit for a good combo of speed and values, but keep in mind that the accuracy does not go up with higher resolution, just the reported values.

This averaging is performed for digital smoothing of the samples, which functionally reduces

noise common with analog devices and circuitry. Therefore, for example, with these default

settings, a new analog voltage measurement will be taken twice a second, and the resulting

average will be equal to 75% of the existing average and 25% of the new sample. If the current

sample needs be displayed, the ‘Avg Weight’ should be set to 100%. High impedance sensors

such as RTDs are mildly prone to noise, so an average weight such as 75% or more can be usedaccording to the docs, RTD is 12 bit, and that is only that one bit different, and RTD is for sure good enough for mash temps, not sure what is actually going on inside BC, but I got MUCH better resolution than 0.9F, my 'steps' were 0.13 degrees F, and RTD was 0.06 degrees F, which makes perfect sense with 11-bit vs 12-bit...

https://www.homebrewtalk.com/thread...omation-software.624198/page-100#post-8751869

no, I have not looked at lookup tables... manually editing tens or hundreds of values for each thermometer probe sounds daunting...

YES, spikes(dropouts actually) are a hardware problem, but they exist in every form of communication, can you imagine the uproar if Netflix shut off your show because the network dropped a packet... that is what happens if you have a script look for a temp to be below a certain value using RTD... AND, you are not getting off that easy... right from the manual:

Code:This averaging is performed for digital smoothing of the samples, which functionally reduces noise common with analog devices and circuitry. Therefore, for example, with these default settings, a new analog voltage measurement will be taken twice a second, and the resulting average will be equal to 75% of the existing average and 25% of the new sample. If the current sample needs be displayed, the ‘Avg Weight’ should be set to 100%. High impedance sensors such as RTDs are mildly prone to noise, so an average weight such as 75% or more can be used

I am going to say that the smoothing algorithm needs improvement.... When the input is missing, instead of slamming to absolute zero, maybe just keep the same value?

according to the docs, RTD is 12 bit, and that is only that one bit different, and RTD is for sure good enough for mash temps, not sure what is actually going on inside BC, but I got MUCH better resolution than 0.9F, my 'steps' were 0.13 degrees F, and RTD was 0.06 degrees F, which makes perfect sense with 11-bit vs 12-bit...

https://www.homebrewtalk.com/thread...omation-software.624198/page-100#post-8751869