My Bru control panel is wired via Ethernet, the Tilt is Bluetooth- can you explain the need for WiFi?

Any ideas on how much range I’ll get with one of these in a dual jacket fermenter. Assuming ESP32 in a plastic enclosure with internal antenna.

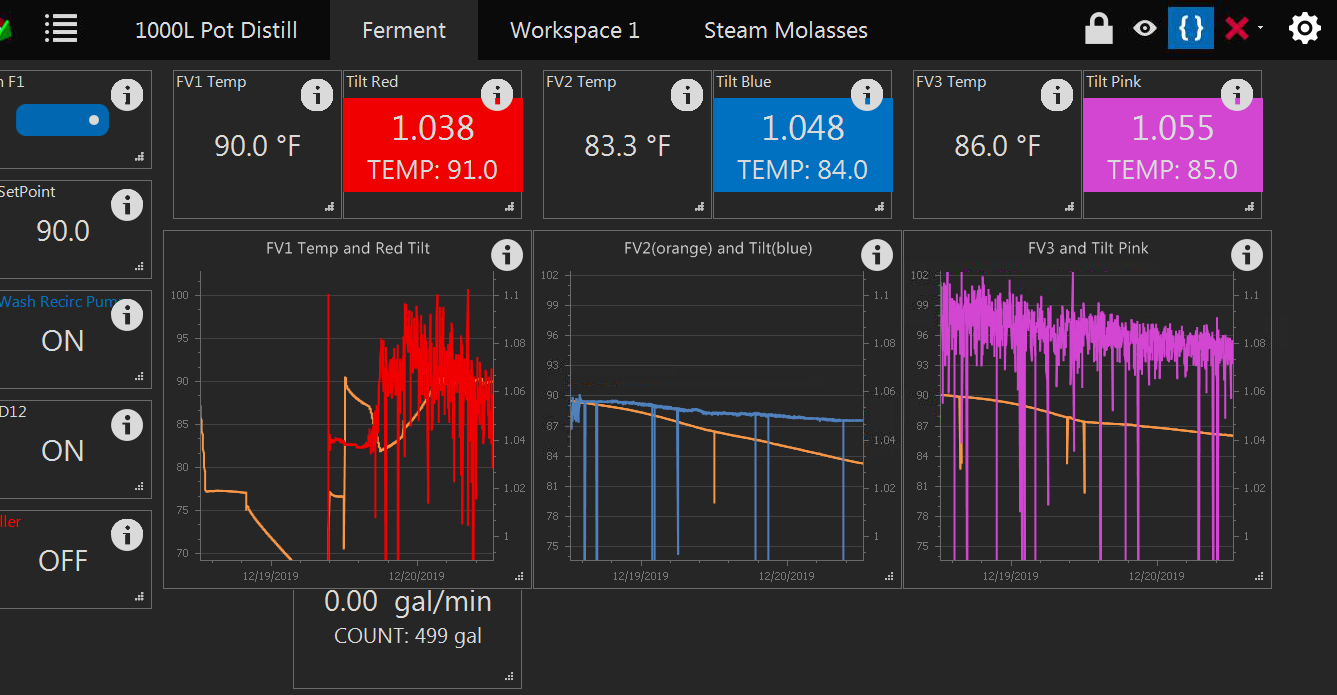

The WiFi is only for the ESP 32. It is only WiFi to BruControl and Blue Tooth to the Tilt. The ESP 32 needs to be near the fermentors. I have a separate room for my fermentors that is temp controlled and has Aluminum coated foam boards which the WiFi signal will not penetrate. I added a wired WiFi Extender simply to provide a WiFi Connection to my Network in the "Cold Room". I have a Tilt repeater and it will extend the Blue Tooth out side the room. The normal Tilt without the repeater is fairly weak. and it can connect to a Glycol Cooled Fermentor if the ESP is with in inches of the blow off outlet. The repeater adds meters. The WiFi will not work at all in my "Cold Room" without the wired WiFi extender.

You can only use the ESP 32 for a Tilt. You can use other pins and Ports (see wiring diagram at BruControl) on the ESP 32 for other things,, but for me that wiring is difficult in another room , so I use it only for the Tilt with some exceptions.

I have created some Digital Outs that are not wired to anything and use them in Scripts to control some things on different Workspaces instead of Button or Switch Elements. I just like the way Digital Outs look and feel for control, and since they are free on the ESP 32, I use them as fake Digital Outs to control real Elements, just like a Button or Switch Element via Scripts.

The ESP 32

only connects to BruControl via WiFi. The ESP 32 connects to the Tilt via

Blue Tooth. The Mega has no Blue Tooth. The WiFi is not necessary for the Tilt except that is the

ONLY way an ESP 32 connects to BruControl.

Bottom line: Tilt = ESP 32!

The wired WiFi extender is only because the ESP 32 is out of range of WiFi signal to the Network.

I also have an Echo Dot in my "Cold Room" that needs the wired WiFi extender to connect.

Once again, there is no physical wiring (or Pins) used with the ESP 32, only Ports 220-224 when using a Tilt.

There are 8 Tilt colors so you can have a max of 8 on the same BruControl. You cannot have two of the same colored Tilts on the same BruControl.

The Tilt is easy to add and you can easily move from Fermentor to Fermentor (prior to fermentation) as it just floats in the Wort. Once in, you need to leave until after you rack. I remove mine before using the Bottom Butterfly Valve. If you were using six fermentors at the same time, you would need 6 Tilts.

You can also simply use the Tilt App on a smart phone but then you cannot use BruControl to tell you when Fermentation is done,

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)