Hi All,

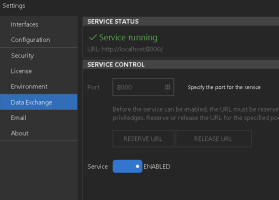

I should be grateful once again if you could give me some guidance, please. I have a Windows 10 running Brucontrol Professional - Version 1.1.0 & Firmware v46F, with the Data Exchange (SQL Server 2019 LocalDB) activated with green text.

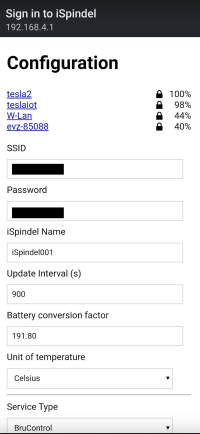

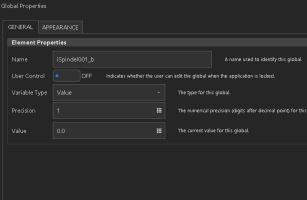

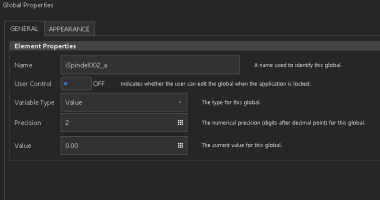

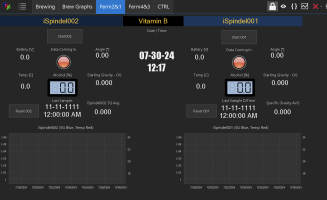

Therefore, I am trying to connect to an iSpindel, and for some reason I cannot get the ispindel to show any values on the Workspace. Although in my search on the Forum on an iSpindel, I have followed the comments to post

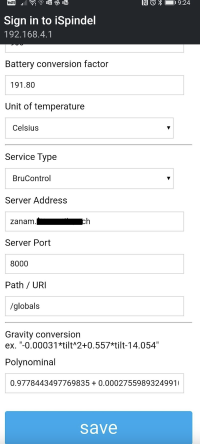

https://www.homebrewtalk.com/thread...ontrol-automation-software.624198/post-899485, as well as making sure I have set the Path to: /globals, but still no values showing. I ran ‘ipconfig’ to make sure I had the ip address of the Brucontrol Computer to set in the iSpindel config.

Also, when I read page 112 of the manual the default connection string for a SQL Server 2019 suggest that my <user>/Documents/BruControl/settings.brusettings for accessing this database using SQL Server 2019 LocalDB should be: Data Source=(LocalDB)\MSSQLLocalDB;AttachDbFilename={0};Integrated Security=True. However, when I checked my settings.brusettings I have: <DBConnection i:nil="true" /> which the manual suggest should be related when using an older SQL Server 2012.

Therefore, as suggested on another post, I did delete ‘settings.brusettings’ but ater I re-activated Brucontrol this file still showed <DBConnection i:nil="true" />.

So, I am slightly puzzled and lost on what I need to do, and hence I should be grateful for your input please? Thanks.

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)