[

{

"id": "3650d7a4f00805cd",

"type": "tab",

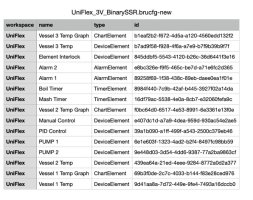

"label": "Find Brucontrol Elements by Workspace",

"disabled": false,

"info": ""

},

{

"id": "1adf9c33a16a2580",

"type": "xml",

"z": "3650d7a4f00805cd",

"name": "xml --> js object",

"property": "payload",

"attr": "",

"chr": "",

"x": 320,

"y": 120,

"wires": [

[

"0d2dafbdd04e43d5",

"ec7022b3cb16c45e"

]

]

},

{

"id": "0d2dafbdd04e43d5",

"type": "function",

"z": "3650d7a4f00805cd",

"name": "js object to rows",

"func": "/*\npayload.Configuration.Workspaces[].Workspace[].Name[]\npayload.Configuration.Workspaces[].Workspace[].Elements[].Element[].Name[]\npayload.Configuration.Workspaces[].Workspace[].Elements[].Element[].ID[]\n\n04/25/23\n\npayload.Configuration.Workspaces[0].Workspace[0].Name[0]\npayload.Configuration.Workspaces[0].Workspace[0].Elements[0].Element[0].Name[0]\npayload.Configuration.Workspaces[0].Workspace[0].Elements[0].Element[0].ID[0]\n\npayload.Configuration.Workspaces\npayload.Configuration.Workspaces[0].Workspace\n*/\n\nmsg.originalData = msg.payload; //save in msg (for debugging)\n\nvar workspaces = msg.payload.Configuration.Workspaces[0].Workspace;\n//var workspaces = msg.payload.Configuration.Workspaces.Workspace;\n//var workspaces = msg.payload.Configuration.Workspaces;\n\n//workspace name get name\nvar wsName = 1;\nvar rows = [];\nfor (let iWS = 0; iWS < workspaces.length; iWS++) {\n let workspace = workspaces[iWS];\n let elements = workspace.Elements[0].Element;\n let workspaceName = workspace.Name[0];\n let workspaceRows = elements.map(el => {\n return {\n workspace: workspaceName,\n id: el.ID[0],\n name: el.Name[0],\n type: el.$[\"i:type\"],\n }\n })\n rows.push(...workspaceRows)\n}\nmsg.payload = rows;\nreturn msg;\n",

"outputs": 1,

"noerr": 0,

"initialize": "",

"finalize": "",

"libs": [],

"x": 320,

"y": 180,

"wires": [

[

"aa64322c2ebdc794"

]

]

},

{

"id": "aa64322c2ebdc794",

"type": "csv",

"z": "3650d7a4f00805cd",

"name": "",

"sep": ",",

"hdrin": "",

"hdrout": "all",

"multi": "mult",

"ret": "\\n",

"temp": "workspace,name,type,id",

"skip": "0",

"strings": true,

"include_empty_strings": "",

"include_null_values": "",

"x": 510,

"y": 180,

"wires": [

[

"fcd6d0634d779913"

]

]

},

{

"id": "8f33db8d99d2624f",

"type": "comment",

"z": "3650d7a4f00805cd",

"name": "____Use this path as a model for your path to 'UniFlex_3V_BinarySSR.brucfg'(XML) under Brucontrol folder ___",

"info": "",

"x": 380,

"y": 280,

"wires": []

},

{

"id": "5d19643d05b00b9e",

"type": "comment",

"z": "3650d7a4f00805cd",

"name": "Convert to JS object",

"info": "",

"x": 330,

"y": 80,

"wires": []

},

{

"id": "cca7dff47396985e",

"type": "comment",

"z": "3650d7a4f00805cd",

"name": "Convert JS object to rows",

"info": "",

"x": 330,

"y": 220,

"wires": []

},

{

"id": "772ad3494f072aea",

"type": "comment",

"z": "3650d7a4f00805cd",

"name": "Convert rows to CSV",

"info": "",

"x": 560,

"y": 220,

"wires": []

},

{

"id": "d33d57244befddd6",

"type": "inject",

"z": "3650d7a4f00805cd",

"name": "",

"props": [

{

"p": "payload"

},

{

"p": "topic",

"vt": "str"

}

],

"repeat": "",

"crontab": "",

"once": false,

"onceDelay": 0.1,

"topic": "",

"payload": "",

"payloadType": "date",

"x": 100,

"y": 80,

"wires": [

[

"3550faeb4f3ea6a8"

]

]

},

{

"id": "3550faeb4f3ea6a8",

"type": "file in",

"z": "3650d7a4f00805cd",

"name": "brucfg",

"filename": "C:/Users/sedgi/OneDrive/Documents/Brucontrol/UniFlex_3V_BinarySSR.brucfg",

"filenameType": "str",

"format": "utf8",

"chunk": false,

"sendError": false,

"encoding": "none",

"allProps": false,

"x": 90,

"y": 220,

"wires": [

[

"1adf9c33a16a2580"

]

]

},

{

"id": "fcd6d0634d779913",

"type": "file",

"z": "3650d7a4f00805cd",

"name": "UniFlex_3V_BinarySSR.brucfg-new.csv",

"filename": "C:/Users/sedgi/OneDrive/Documents/BeerSmith3/UniFlex_3V_BinarySSR.brucfg-new.csv",

"filenameType": "str",

"appendNewline": true,

"createDir": false,

"overwriteFile": "true",

"encoding": "none",

"x": 680,

"y": 340,

"wires": [

[]

]

},

{

"id": "d70cbb87bbf8033e",

"type": "comment",

"z": "3650d7a4f00805cd",

"name": "Define where you want the csv file to be written each time script runs--most close app viewing file before running again",

"info": " - ",

"x": 860,

"y": 380,

"wires": []

},

{

"id": "afa556db999f82e8",

"type": "comment",

"z": "3650d7a4f00805cd",

"name": "VERY IMPORTANT: Only use backup files or copy of current default.brucfg",

"info": "",

"x": 260,

"y": 40,

"wires": []

},

{

"id": "c42c37fd76a41461",

"type": "comment",

"z": "3650d7a4f00805cd",

"name": "(must close app viewing .csv before running again)",

"info": "",

"x": 650,

"y": 420,

"wires": []

},

{

"id": "ec7022b3cb16c45e",

"type": "debug",

"z": "3650d7a4f00805cd",

"name": "debug XML import",

"active": true,

"tosidebar": true,

"console": false,

"tostatus": false,

"complete": "payload",

"targetType": "msg",

"statusVal": "",

"statusType": "auto",

"x": 530,

"y": 80,

"wires": []

}

]

![Craft A Brew - Safale BE-256 Yeast - Fermentis - Belgian Ale Dry Yeast - For Belgian & Strong Ales - Ingredients for Home Brewing - Beer Making Supplies - [3 Pack]](https://m.media-amazon.com/images/I/51bcKEwQmWL._SL500_.jpg)