You can just wrap your fingers around the side handles and your thumbs inside the handles and lift. Simple enough to transport that wayI was looking at it more for storage/transportation purposes. Meaning a way to hold the lid on when moving the unit around when empty. The pictures on morebeer show the clamps holding the glass lid down. Outside of that if it's just for the boil extender or other accessories I can definitely live with it

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Brewzilla Gen4 Discussion/Tips Talk

- Thread starter stealthfixr

- Start date

Help Support Homebrew Talk:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

rtstrider

Well-Known Member

- Joined

- Dec 12, 2016

- Messages

- 1,310

- Reaction score

- 847

And that works too! Just tried it lol Ready for brew day already! Saturday can't get here soon enoughYou can just wrap your fingers around the side handles and your thumbs inside the handles and lift. Simple enough to transport that way

agentbud

Well-Known Member

Did you by chance time the heating? How long from room temp water to strike and again how long from strike to boil?Just got through Brewzilla gen4. Is it extremely hard to clamp down the lid? My clamps seem like they sit a bit low and I'm afraid of busting the lid. Ran through a water only batch tonight to get a feel for things. The 120 volt 9.25 gallon has around a .5 gallon per hour boil off.

rtstrider

Well-Known Member

- Joined

- Dec 12, 2016

- Messages

- 1,310

- Reaction score

- 847

It saved a graph that shows it took about 50 min to go from room temp to 150F. Then it took about 16 min to go from 150F to 170F. It took around 38 min to go from 170f to boiling. Hopefully that helps!Did you by chance time the heating? How long from room temp water to strike and again how long from strike to boil?

agentbud

Well-Known Member

Did you use the neoprene jacket?It saved a graph that shows it took about 50 min to go from room temp to 150F. Then it took about 16 min to go from 150F to 170F. It took around 38 min to go from 170f to boiling. Hopefully that helps!

Pennine

Well Known Fool

- Joined

- Sep 10, 2019

- Messages

- 559

- Reaction score

- 2,689

Thanks for the updates I am keen to hear about your brewday. I am trying to decide between the 220v brewzilla and the Grainfather S40.It saved a graph that shows it took about 50 min to go from room temp to 150F. Then it took about 16 min to go from 150F to 170F. It took around 38 min to go from 170f to boiling. Hopefully that helps!

$33.99 ($17.00 / Count)

$41.99 ($21.00 / Count)

2 Pack 1 Gallon Large Fermentation Jars with 3 Airlocks and 2 SCREW Lids(100% Airtight Heavy Duty Lid w Silicone) - Wide Mouth Glass Jars w Scale Mark - Pickle Jars for Sauerkraut, Sourdough Starter

Qianfenie Direct

$53.24

1pc Hose Barb/MFL 1.5" Tri Clamp to Ball Lock Post Liquid Gas Homebrew Kegging Fermentation Parts Brewer Hardware SUS304(Liquid Hose Barb)

yunchengshiyanhuqucuichendianzishangwuyouxiangongsi

$10.99 ($31.16 / Ounce)

Hornindal Kveik Yeast for Homebrewing - Mead, Cider, Wine, Beer - 10g Packet - Saccharomyces Cerevisiae - Sold by Shadowhive.com

Shadowhive

$39.22 ($39.22 / Count)

Brewer's Best Home Brew Beer Ingredient Kit - 5 Gallon (Mexican Cerveza)

Amazon.com

$33.95

Five Star - 6022b_ - Star San - 32 Ounce - High Foaming Sanitizer

Bridgeview Beer and Wine Supply

$172.35

2 Inch Tri Clamp Keg Manifold With Ball Lock Posts, Pressure Gauge, PRV (0-30 PSI) – Homebrew, Fermentation, Kegging System

wuhanshijiayangzhiyimaoyiyouxiangongsi

$20.94

$29.99

The Brew Your Own Big Book of Clone Recipes: Featuring 300 Homebrew Recipes from Your Favorite Breweries

Amazon.com

$58.16

HUIZHUGS Brewing Equipment Keg Ball Lock Faucet 30cm Reinforced Silicone Hose Secondary Fermentation Homebrew Kegging Brewing Equipment

xiangshuizhenzhanglingfengshop

$53.24

1pc Hose Barb/MFL 1.5" Tri Clamp to Ball Lock Post Liquid Gas Homebrew Kegging Fermentation Parts Brewer Hardware SUS304(Gas MFL)

Guangshui Weilu You Trading Co., Ltd

$176.97

1pc Commercial Keg Manifold 2" Tri Clamp,Ball Lock Tapping Head,Pressure Gauge/Adjustable PRV for Kegging,Fermentation Control

hanhanbaihuoxiaoshoudian

$7.79 ($7.79 / Count)

Craft A Brew - LalBrew Voss™ - Kveik Ale Yeast - For Craft Lagers - Ingredients for Home Brewing - Beer Making Supplies - (1 Pack)

Craft a Brew

$22.00 ($623.23 / Ounce)

AMZLMPKNTW Ball Lock Sample Faucet 30cm Reinforced Silicone Hose Secondary Fermentation Homebrew Kegging joyful

无为中南商贸有限公司

rtstrider

Well-Known Member

- Joined

- Dec 12, 2016

- Messages

- 1,310

- Reaction score

- 847

Not yet. Morebeer shows out of stock for the Gen 4 model. That's definitely on the to do list as soon as they have it in stock!Did you use the neoprene jacket?

Just noticed this on youtube

rtstrider

Well-Known Member

- Joined

- Dec 12, 2016

- Messages

- 1,310

- Reaction score

- 847

OK so I just brewed a Bells Two hearted clone with 13.96 lbs of grain. Had a few issues that I know would be solved with a brew bag. I hit 74% brewhouse efficiency and can confirm that if you're using the pump and pump arm hose to transfer with the 110 volt 9.25 gallon unit aim for a 6.5 gallon pre boil volume. Now the issues I ran into were the pump hose got clogged and I ended up with a handful of grain or so in the boil. There was a hint of scorching on the bottom but it was less than the size of a dime. Other issue I had today was hitting a boil. It was very slightly breezy and it took a bit longer to hit a boil. Once it did it held nicely!

rtstrider

Well-Known Member

- Joined

- Dec 12, 2016

- Messages

- 1,310

- Reaction score

- 847

I think my crush may be too fine. I'm crushing as tight as the grain mill can go and double crushing. I was watching this and about 2:30 in they said the mill is set at .035. Mine is probably around .025 - .023 ish. Next question I have is do you stir the mash with this unit every 15 min or so or do you just set and forget the pump? I've been stirring every 15 min and the wort clarity is good, but, I feel it would be significantly clearer if I just left it alone with the the pump. The issue I'm having is really just grain either getting in the pump or clogging the bottom of the malt pipe so it overflows. I do use 5% rice hulls but thinking about widening the gap on the mill to the credit card sized gap just to see what happens. I've also thought about saying heck with it and just getting a brew bag for the malt pipe, but, wanted to see if anyone else has run into this?

I stir about 3 times but let everthing settle from about 40 minutes in.

Regarding crush why not try half the grain at your narrow gap and half at the .035 rather than a dramatic change.

Not sure a double crush will be needed.

Adjust your flow rate on the recirculation, I normally start off quite slow but by the end of the mash the tap is open fully and the grain bed is often only just saturated.

Regarding crush why not try half the grain at your narrow gap and half at the .035 rather than a dramatic change.

Not sure a double crush will be needed.

Adjust your flow rate on the recirculation, I normally start off quite slow but by the end of the mash the tap is open fully and the grain bed is often only just saturated.

rtstrider

Well-Known Member

- Joined

- Dec 12, 2016

- Messages

- 1,310

- Reaction score

- 847

What gap do you use and what's the typical efficiency? I'm not really chasing efficiency per se. I'm looking more for repeatabilityI stir about 3 times but let everthing settle from about 40 minutes in.

Regarding crush why not try half the grain at your narrow gap and half at the .035 rather than a dramatic change.

Not sure a double crush will be needed.

Adjust your flow rate on the recirculation, I normally start off quite slow but by the end of the mash the tap is open fully and the grain bed is often only just saturated.

I'm using a Maltzilla mill which is a bit of an odd beast, working with large diamond gritted non gnurled rollers and it tends to leave the husks completely intact looking like rice hulls really but a good crush inside the husk.

I do condition the grain which I think helps to make less flour, my gap is 0.75mm which apparently is 0.03 inch.

I'm using a Guten 70 litre with a few modifications so my efficiencies probably don't translate well, but in brewfather for a 25 litre batch my figures are 89% mash efficiency and 90% conversion efficiency. Brewhouse varies depending on the amount of hops used.

I do condition the grain which I think helps to make less flour, my gap is 0.75mm which apparently is 0.03 inch.

I'm using a Guten 70 litre with a few modifications so my efficiencies probably don't translate well, but in brewfather for a 25 litre batch my figures are 89% mash efficiency and 90% conversion efficiency. Brewhouse varies depending on the amount of hops used.

I recently switched back to skipping the malt pipe altogether and just using a BIAB for the mash. My efficiency went up a lot, and no need to worry about crush size (and can fit almost 30% more malt). I'm waiting for Kegland's new sturdier false bottoms to get released in the states, and then I may never go back to the malt pipe.

agentbud

Well-Known Member

Ok, I am this close (thumb and pointer finger about 2 inches apart) to taking the plunge and buying the Brewzilla Gen 4 35L 110V. But before I do, I have a couple questions.

1) I currently do BIAB no sparge and would like to continue doing full volume mash / no sparge. Although the 35L version looks plenty big enough for normal brews, it does not appear to be big enough for a full volume mash for really big beers, so I was thinking of adding on one of the boiler extension kits. Do any of you currently use a boiler extension for the purpose of full volume mashing and does it work ok for that purpose?

2) Assuming I do use an extension, is it required that you also get one of the longer malt pipes or will the original (shorter) malt pipe work ok with the boiler extension?

3) I saw a video on Kegland where Kee talked about a change in the false bottom for the Gen 4 that has a redirection plate attached to the underside that directs the wort toward the sides instead of it going straight down to the drain hole. Does anyone have one of these updated false bottoms or are they not yet available?

Thanks...

1) I currently do BIAB no sparge and would like to continue doing full volume mash / no sparge. Although the 35L version looks plenty big enough for normal brews, it does not appear to be big enough for a full volume mash for really big beers, so I was thinking of adding on one of the boiler extension kits. Do any of you currently use a boiler extension for the purpose of full volume mashing and does it work ok for that purpose?

2) Assuming I do use an extension, is it required that you also get one of the longer malt pipes or will the original (shorter) malt pipe work ok with the boiler extension?

3) I saw a video on Kegland where Kee talked about a change in the false bottom for the Gen 4 that has a redirection plate attached to the underside that directs the wort toward the sides instead of it going straight down to the drain hole. Does anyone have one of these updated false bottoms or are they not yet available?

Thanks...

rtstrider

Well-Known Member

- Joined

- Dec 12, 2016

- Messages

- 1,310

- Reaction score

- 847

I mashed almost 14lbs of grain this past weekend. The malt pipe was pretty full as is. There's no way that would've been able to do a full volume mash. I also had quite a few issues, but, going to chalk that up to crushing the grain too fine. Mine didn't come with the diffuser bottom plate deal. It's just the plain jane plate with holes and feet. I don't think they're available yet. I'm still waiting on the neoprene insulated jacket kit to become available here in the states. From what I saw the Aussie kit insulates the Brewzilla unit and comes with an insulator for the sparge arm. Hoping we get the same here. If not then I'd just settle for the neoprene insulation and get something at the hardware store to insulate the recirculation pipe.Ok, I am this close (thumb and pointer finger about 2 inches apart) to taking the plunge and buying the Brewzilla Gen 4 35L 110V. But before I do, I have a couple questions.

1) I currently do BIAB no sparge and would like to continue doing full volume mash / no sparge. Although the 35L version looks plenty big enough for normal brews, it does not appear to be big enough for a full volume mash for really big beers, so I was thinking of adding on one of the boiler extension kits. Do any of you currently use a boiler extension for the purpose of full volume mashing and does it work ok for that purpose?

2) Assuming I do use an extension, is it required that you also get one of the longer malt pipes or will the original (shorter) malt pipe work ok with the boiler extension?

3) I saw a video on Kegland where Kee talked about a change in the false bottom for the Gen 4 that has a redirection plate attached to the underside that directs the wort toward the sides instead of it going straight down to the drain hole. Does anyone have one of these updated false bottoms or are they not yet available?

Thanks...

agentbud

Well-Known Member

Thanks. I received an update from morebeer today that said they expect the neoprene jackets to arrive Nov 11.I mashed almost 14lbs of grain this past weekend. The malt pipe was pretty full as is. There's no way that would've been able to do a full volume mash. I also had quite a few issues, but, going to chalk that up to crushing the grain too fine. Mine didn't come with the diffuser bottom plate deal. It's just the plain jane plate with holes and feet. I don't think they're available yet. I'm still waiting on the neoprene insulated jacket kit to become available here in the states. From what I saw the Aussie kit insulates the Brewzilla unit and comes with an insulator for the sparge arm. Hoping we get the same here. If not then I'd just settle for the neoprene insulation and get something at the hardware store to insulate the recirculation pipe.

agentbud

Well-Known Member

How many gallons of water did you have with that mash of 14 lbs of grain and how much did you add during sparge?I mashed almost 14lbs of grain this past weekend. The malt pipe was pretty full as is. There's no way that would've been able to do a full volume mash. I also had quite a few issues, but, going to chalk that up to crushing the grain too fine. Mine didn't come with the diffuser bottom plate deal. It's just the plain jane plate with holes and feet. I don't think they're available yet. I'm still waiting on the neoprene insulated jacket kit to become available here in the states. From what I saw the Aussie kit insulates the Brewzilla unit and comes with an insulator for the sparge arm. Hoping we get the same here. If not then I'd just settle for the neoprene insulation and get something at the hardware store to insulate the recirculation pipe.

rtstrider

Well-Known Member

- Joined

- Dec 12, 2016

- Messages

- 1,310

- Reaction score

- 847

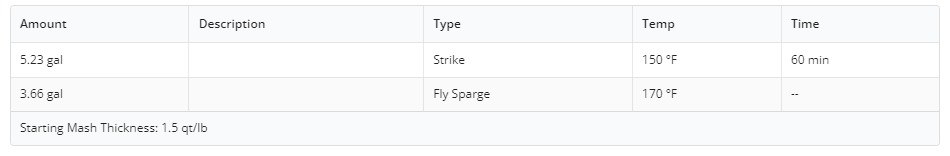

How many gallons of water did you have with that mash of 14 lbs of grain and how much did you add during sparge?

agentbud

Well-Known Member

Using an online BIAB calculator, it looks like a full volume mash of 14 lbs of grain for a 5.5 gallon batch would equate to a total mash volume of around 9.5 to 9.75 gallons (depending on evaportaion / absorption rates). Based on that it seems to me that the addition 3.1 gallons of space the boiler extension provides (total 12.3 gallons of space) would be plenty enough to do a full volume mash of 14 lbs, possibly enough space to full-volume mash up to around 22-23 lbs. Would you concur?

agentbud

Well-Known Member

Anyone have a good beersmith equipment profile for the brewzilla gen 4 35L 110v system?

rtstrider

Well-Known Member

- Joined

- Dec 12, 2016

- Messages

- 1,310

- Reaction score

- 847

I don't have that but for that same systemAnyone have a good beersmith equipment profile for the brewzilla gen 4 35L 110v system?

If you start with 6.5 gallons water at a 60 min boil you'll end up with 5.5 gallons of wort in the fermenter. Now that's if you're using the sparge arm/pump to transfer. That's what's been working for me at least

Have done two batches on the 35L gen 4 (10L batches) with the neoprene jacket on and the recirc arm on. Seeing wild changes in temperature - overshooting - both when using PID and otherwise. Has anyone had better luck with it? If yes, request PID settings please.

Thank you.

Thank you.

Is this with the redesigned false bottom?Have done two batches on the 35L gen 4 (10L batches) with the neoprene jacket on and the recirc arm on. Seeing wild changes in temperature - overshooting - both when using PID and otherwise. Has anyone had better luck with it? If yes, request PID settings please.

Thank you.

One thing I like about my Anvil 10.5 is the temps are within 1C (maybe 2) with recirc.

agentbud

Well-Known Member

I checked with both morebeer and kegland and what I am hearing from both is the updated false bottom (or rather the redirection/disperse plate that attaches to the bottom of the existing false bottom) is not yet available. If you know otherwise, let me knowIs this with the redesigned false bottom?

One thing I like about my Anvil 10.5 is the temps are within 1C (maybe 2) with recirc.

Gunkleneil

Well-Known Member

- Joined

- Mar 7, 2022

- Messages

- 73

- Reaction score

- 65

Don't have mine yet, late November maybe, but Kegland had a YouTube video about adding settings for the PID. It seemed pretty informativeHave done two batches on the 35L gen 4 (10L batches) with the neoprene jacket on and the recirc arm on. Seeing wild changes in temperature - overshooting - both when using PID and otherwise. Has anyone had better luck with it? If yes, request PID settings please.

Thank you.

Tried those settings. In fact, David Heath has a video as well. Unfortunately none of them worked. I think that once it reaches close to mash temp, the simplest way is to reduce the heating element power. That is something I am going to try next.Don't have mine yet, late November maybe, but Kegland had a YouTube video about adding settings for the PID. It seemed pretty informative

Similar threads

- Replies

- 6

- Views

- 831

- Replies

- 46

- Views

- 13K

- Replies

- 46

- Views

- 16K

![Craft A Brew - Safale BE-256 Yeast - Fermentis - Belgian Ale Dry Yeast - For Belgian & Strong Ales - Ingredients for Home Brewing - Beer Making Supplies - [3 Pack]](https://m.media-amazon.com/images/I/51bcKEwQmWL._SL500_.jpg)