I did my first mash with the BrewPI Spark two weeks ago, using a recirculating BIAB setup.

It worked pretty well, although there certainly are improvements to be made.

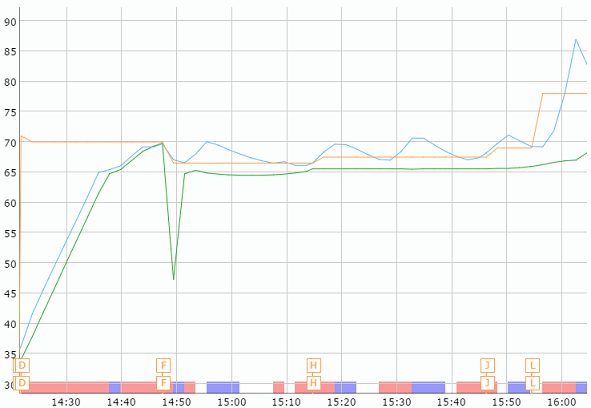

There was a bit of overshooting, but I think that mainly has to do with my configuration, which needs to be dialed in.

ORANGE is target temp, BLUE is temp sensor at pump, which is used to control the heating element, and GREEN is a sensor submerged in the grain bed.

The green spike at 14:50 was when I removed the sensor, for adding the grains, the blue spike at 16:05 was when I applied a gas burner as supplementary heating, and has nothing to do with the software.

There is a long mash related thread here:

https://community.brewpi.com/t/using-brewpi-0-4-for-mashing/1184

Here is my list of issues, which may or may not be accurate:

- The touch screen is currently for display only, you still have to control everything from the web interface on the RaspberryPI

- WIFI doesn't work yet, so you have to have a USB connection between the RaspberryPI and the BrewPI Spark

- You still can only apply temperature control to one vessel at a time

- The web interfacet on the RaspberryPI is still 100% fermentation oriented, which can be confusing when you are mashing

- While it is possible to do temperature control, as well as turning relays on/off from the web interface, regulating the boil requires low level commands to be sent from an undocumented php page, in the format of messageType = writeDevice, message = {“i”:, “w”:<0-100>}

- No documentation. Until the web interface has been redone, you need to find your answers on https://community.brewpi.com

Bottom line is that I'm pretty happy with it for now, even though I am really looking forward for future improvements

Cheers ...