Murphys_Law

Well-Known Member

This is a cool little device. I'm not looking for absolute numbers but rather trends. I like being able to see when fermentation flattens out and then I check SG with a hydrometer for my records.

this is a cool little device. I'm not looking for absolute numbers but rather trends. I like being able to see when fermentation flattens out and then i check sg with a hydrometer for my records.

I am glad that silly Amazon talk is over...

No surprise on temp affecting the reading. My guess is they have to better understand and manage the device's correlation between temp and gravity. I would bet the lag between the body temp and the sensor temp wreaks havoc on the calculations.

But at the end of the day it is a very cool device and platform that is good now for the money. It will only get better with fine tuning and updated supporting applications. It's not perfectly accurate in one single reading but certainly over the course of a short period of time, it's average it pretty much spot on.

I'm pretty impressed with the device, and find great utility in tracking SG to know when to adjust temperature, etc. But the other thing I learned on my first ferment had more to do with my temp control. Having temp logging near the surface of the beer is pretty useful.

A little background on my setup:

- Upright freezer with dual stage love controller

- Temp probe in thermowell in the center of a better bottle fermenter

- Heating accomplished with fermwrap

- Temp threshold set at 0.4 degrees single stage (without heater)

- Temp threshold set at 1.0 degrees dual stage (when heater needed)

I always assumed this worked fairly well, but never logging temp in the beer, never knew for sure. In the attached plot, you can see that this worked pretty well while fermentation was active. Temperature was very stable because moving liquid kept temperature at center of fermenter the same as temperature at surface of fermenter. However, as fermentation finished and the beer stopped moving, I started getting 2-4 deg F swings due to delay in cooling the center of the beer relative to the surface. (The change in average temp was due to a two step ramp of set point near end of fermentation).

So on 5/24, I moved the temp probe to the outside of the fermenter, covered with foam and taped in place. From that point on, the temperature variation was mostly less than the 1 deg resolution of the brewometer. Very interesting.

For my next batch, I plan to start out in this configuration (probe covered in foam and taped to fermenter) and see what the beer temp does. At the very least, I think my new procedure will include moving probe out of thermowell once fermentation is complete.

I expect the question: Does this 2-4 deg temp change matter? I am leaning toward yes due to air exchange as the temperature changes (S airlock bubbles both ways), but am open to other thoughts.

Anyway, I'm enjoying the new toy and have had no problems so far. Thinking about a second brewometer, as the visual progress in the second fermenter is a little different, even though everything should be identical (split 10g batch). Sorry for the long-winded post, but just thought I'd share my learning experience. I'm sure everyone's system is a little different, but the opportunity to learn one's own is pretty cool.

One other note: The SG drop at the beginning (and associated rise after 12 hours) is due to adding my yeast starter, which stayed layered at the top (where brewometer floats) until fermentation got active.

I think the main issue with any given reading is the potential for there to be either krausen or bubbles adhering to the device. One of those new super-hydrophobic materials as a coating would be an interesting experiment, but I contacted the coating manufacturer and they stated they are not rated for food contact.It's not perfectly accurate in one single reading but certainly over the course of a short period of time, it's average it pretty much spot on.

Very interesting. I've only had my Brewometer for about a week, so when it arrived I just chucked it into a 13-gallon batch of beer that had already finished fermenting. The gravity readings didn't fluctuate much (mainly between 1.007 and 1.01), but the temperature readings bounced between 68 (the setpoint temperature) and 72. That upper level worries me a bit.I always assumed this worked fairly well, but never logging temp in the beer, never knew for sure. In the attached plot, you can see that this worked pretty well while fermentation was active. Temperature was very stable because moving liquid kept temperature at center of fermenter the same as temperature at surface of fermenter. However, as fermentation finished and the beer stopped moving, I started getting 2-4 deg F swings due to delay in cooling the center of the beer relative to the surface. (The change in average temp was due to a two step ramp of set point near end of fermentation).

So on 5/24, I moved the temp probe to the outside of the fermenter, covered with foam and taped in place. From that point on, the temperature variation was mostly less than the 1 deg resolution of the brewometer. Very interesting.

That's what I did. I entered the OG (as measured by refractometer) and predicted FG manually for gauges displaying the current ABV and the percentage of fermentation completed.In the next version, I'll hard-code my OG so the gauges don't lose sight of the value if I keep the report filters at 10 days.

The inventors developed a Google Sheets template which they've shared on their website and it contains the trend lines. I agree that it's not of much use. I also agree that scatter plots are easier on the eye than the mass of connected lines.One thing I've noticed about these graphs: People are using trend lines. A "moving average" may be a better indicator. Not sure if this is a graph that someone here developed or if it "comes with" the device.

One thing I've noticed about these graphs: People are using trend lines. A "moving average" may be a better indicator. Not sure if this is a graph that someone here developed or if it "comes with" the device.

to me, the 1 deg F resolution in temperature is annoying and surprising. I would imagine that any thermocouple even a cheap one, can do 0.1-0.2F easily. Even 0.3F would be ok by me.

SG values have an excellent resolution of 1 gravity point but fluctuate randomly by 2-3 points so that's not useful. Yet temperature is stable to within 0.1F and they don;t have thermocouples that could measure that?

Very interesting. I've only had my Brewometer for about a week, so when it arrived I just chucked it into a 13-gallon batch of beer that had already finished fermenting. The gravity readings didn't fluctuate much (mainly between 1.007 and 1.01), but the temperature readings bounced between 68 (the setpoint temperature) and 72. That upper level worries me a bit.

My setup is a plastic, 60-liter Speidel fermenter in a chest freezer. I just fit an orange carboy cap over the top of the hole in the lid and insert a stainless thermowell into the large opening and put a blowoff hose over the smaller opening. I put the other end of the hose in a container of StarSan. I never have blowoff problems with the Speidels, so it really just serves as an airlock.

The thermowell puts the temperature sensor for the Brewbit controller right in the center of a 10-gallon batch. I had the controller set for 68 degrees with a 0.5-degree threshold and it did a good job of keeping the (center of) beer between 67.5 and 68.5 by cycling the chest freezer's compressor and a 50W reptile heater that's taped to the walls of the freezer.

It's clear that the Brewometer's temperature readings fluctuated in sync with the freezer/heater cycles, but they rose about 3.5 degrees higher than the thermowell reading and that concerns me. I'll probably leave things alone for a first full fermentation cycle (I might ferment a couple of degrees cooler than planned) but if I still see such large swings I'll try taping the temperature probe to the outside of the Speidel to see if it helps things.

Thanks for sharing your info!

I knew there would be stratification issues, but I didn't realize that the temperature between the center of the vessel and the top would vary by almost 4 degrees until the Brewometer showed me, so it's already proven itself worth the price of purchase.I probably should not go down the rabbit hole, but driving a refrigeration controller of of the temp probe in the center of your wort will cause a lot of stratification. The wort near the surface of the fermenter will end up much colder than the center by the time the sensor and the controller's hysteresis gap tells the compressor to cycle off. That creates the temp swings. The Brewometer is at the top surface of the liquid, so expect it to read dramatically different temps than the center.

I knew there would be stratification issues, but I didn't realize that the temperature between the center of the vessel and the top would vary by almost 4 degrees until the Brewometer showed me, so it's already proven itself worth the price of purchase.

I have 3 logging temperature devices (Brewometer and 2 Brewbit probes) so for my next batch I'll try to use them all. I'll stick one probe to the side of the fermenter with some insulation and maybe I'll try pulling the other up the thermowell so that it's only an inch or two below the surface. Not sure how much heat/cold the stainless thermowell will conduct from above/below, but it'll be interesting to see.

I also have a fan that I've been meaning to install in the chest freezer. That should help even out the ambient air temperature.

I would expect stratification to be less of an issue during active fermentation while the wort is churning around the fermenter, right? All in all, I'll be happy with a 1-degree swing. That's what I already have a the center of the Speidel, but I'd just like to make sure that there aren't parts of it hitting the 70s.

The temp sensor is not a thermocouple. It is a digital sensor, and it is mounted to the circuit board in the device. It is not in contact with the wort. Go back a few pages and you can see where we discussed it's accuracy.

If you are concerned with dead on SG accuracy, use a hydrometer. If you are interested in the trend, then the 2-3 SG point swing is no big deal. You are expecting too much for an electronic device like this at this price point to have 0.001 accuracy. The resolution is easy to do... But accuracy is another animal.

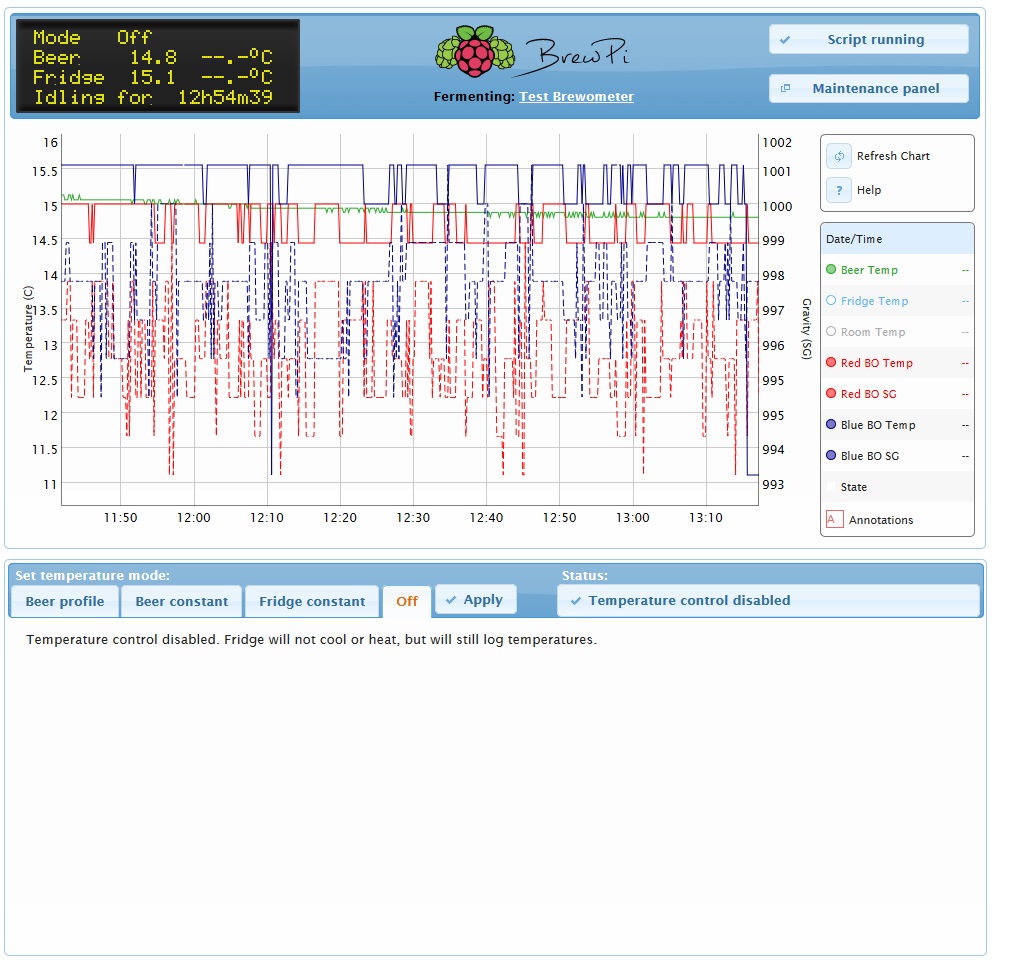

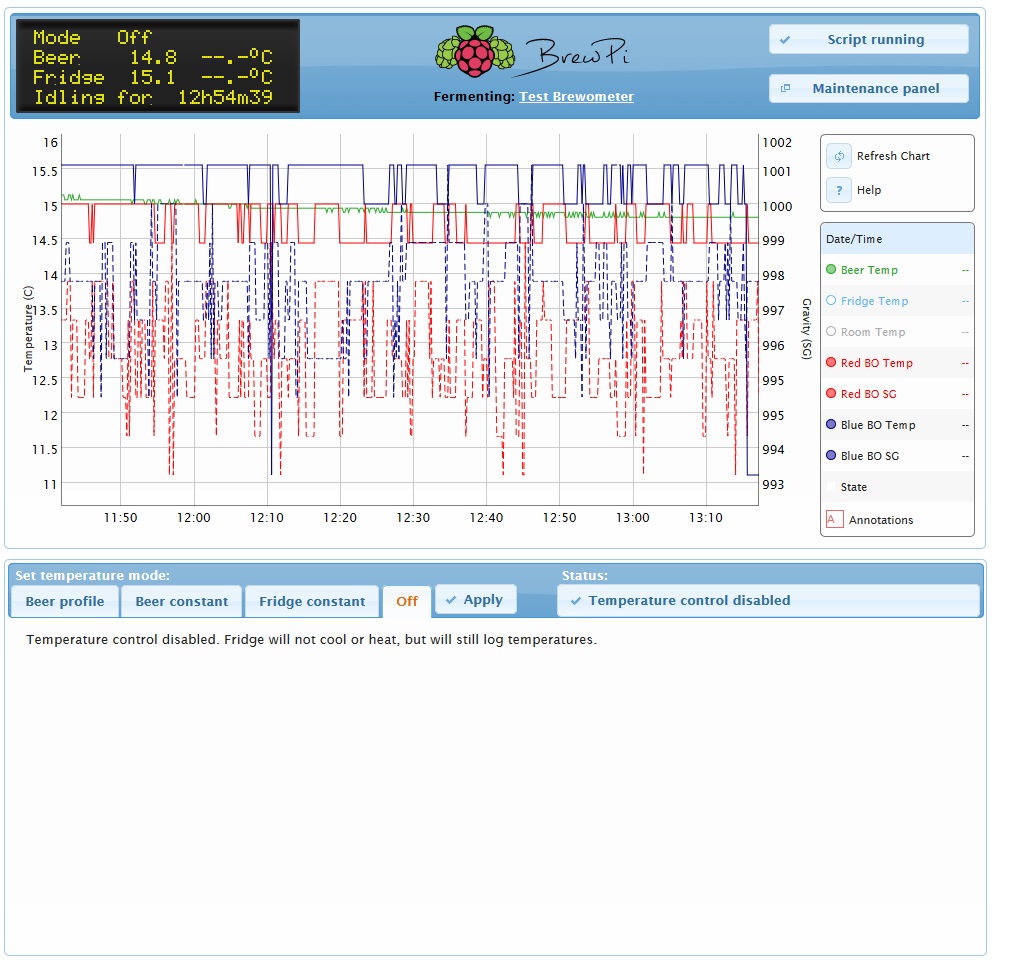

I have seen the data integrated with the BrewPi,[...]

Link?

Cheers!

[edit] nvm, found an example:

Woof.

'Course, that's two Brewometer traces, but still, hella busy...

The temp sensor is not a thermocouple. It is a digital sensor, and it is mounted to the circuit board in the device. It is not in contact with the wort. Go back a few pages and you can see where we discussed it's accuracy.

If you are concerned with dead on SG accuracy, use a hydrometer. If you are interested in the trend, then the 2-3 SG point swing is no big deal. You are expecting too much for an electronic device like this at this price point to have 0.001 accuracy. The resolution is easy to do... But accuracy is another animal.

Yeah I found a few posts on the BrewPi forms with some people trying to integrate this better. As of right now though, you would need to edit the data second hand like you mentioned to really make sense of it... Though I have also read that a SG sensor is in the works for the BrewPi, but is on the backburner until they find a way to use the BrewPi to control mash temperatures and such... Still, might be an interesting project to look into. The BrewPi integration is still rather new.

I got my brewpi running for a few days now with the brewpi+ brewometer integration by sbowler, and after his averaging fixes and with some tweaking on the graphing I think I now like how this looks...

There are also updated instructions on his github page.

Cheers,

-Th

[...]Also - any recommendations for a good USB hub to add to a RPI2 since mine only has two ports... 1 for power and 1 for the Wifi dongle and for this I'll need to add a BLE dongle as well.

I would assume these are just additions to the RPI side of things, but just want to make sure those tweaks work with the Arduino version of Brewpi (i.e. the legacy branch) and not the newer branch?

Also - any recommendations for a good USB hub to add to a RPI2 since mine only has two ports... 1 for power and 1 for the Wifi dongle and for this I'll need to add a BLE dongle as well.