I'm pretty impressed with the device, and find great utility in tracking SG to know when to adjust temperature, etc. But the other thing I learned on my first ferment had more to do with my temp control. Having temp logging near the surface of the beer is pretty useful.

A little background on my setup:

- Upright freezer with dual stage love controller

- Temp probe in thermowell in the center of a better bottle fermenter

- Heating accomplished with fermwrap

- Temp threshold set at 0.4 degrees single stage (without heater)

- Temp threshold set at 1.0 degrees dual stage (when heater needed)

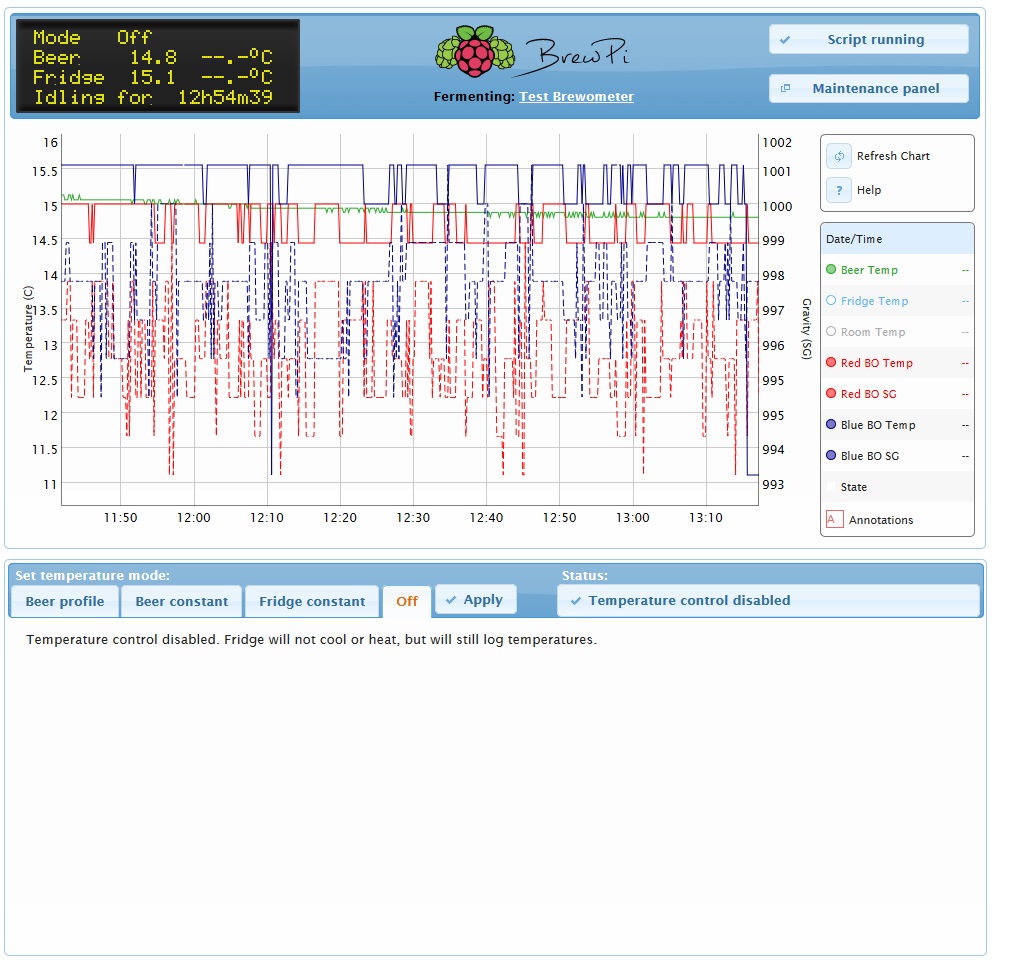

I always assumed this worked fairly well, but never logging temp in the beer, never knew for sure. In the attached plot, you can see that this worked pretty well while fermentation was active. Temperature was very stable because moving liquid kept temperature at center of fermenter the same as temperature at surface of fermenter. However, as fermentation finished and the beer stopped moving, I started getting 2-4 deg F swings due to delay in cooling the center of the beer relative to the surface. (The change in average temp was due to a two step ramp of set point near end of fermentation).

So on 5/24, I moved the temp probe to the outside of the fermenter, covered with foam and taped in place. From that point on, the temperature variation was mostly less than the 1 deg resolution of the brewometer. Very interesting.

For my next batch, I plan to start out in this configuration (probe covered in foam and taped to fermenter) and see what the beer temp does. At the very least, I think my new procedure will include moving probe out of thermowell once fermentation is complete.

I expect the question: Does this 2-4 deg temp change matter? I am leaning toward yes due to air exchange as the temperature changes (S airlock bubbles both ways), but am open to other thoughts.

Anyway, I'm enjoying the new toy and have had no problems so far. Thinking about a second brewometer, as the visual progress in the second fermenter is a little different, even though everything should be identical (split 10g batch). Sorry for the long-winded post, but just thought I'd share my learning experience. I'm sure everyone's system is a little different, but the opportunity to learn one's own is pretty cool.

One other note: The SG drop at the beginning (and associated rise after 12 hours) is due to adding my yeast starter, which stayed layered at the top (where brewometer floats) until fermentation got active.

![Craft A Brew - Safale BE-256 Yeast - Fermentis - Belgian Ale Dry Yeast - For Belgian & Strong Ales - Ingredients for Home Brewing - Beer Making Supplies - [3 Pack]](https://m.media-amazon.com/images/I/51bcKEwQmWL._SL500_.jpg)