I have been looking at improvements i can make to my brewing method/setup to improve beer quality and I have been aiming to make incremental improvements each brew.

I currently partial mash on a gas hob so the obvious area of improvement is to go Electric (so i have stricter Mash temperature control) and All Grain.

However that is also a big investment so while this is a longer term goal, i am looking at other areas of improvement i can make in the mean time.

My improvements so far have centered around Yeast viability/health, so i focused on:

Fermentation Temp Control (invested in DIY Temp Controlled Fridge)

Yeast Re-hydration (if using dry)

Yeast Storage (if using liquid)

Yeast Nutrient (end of boil)

Yeast Starter (invested in Erlenmeyer Flask + Magnetic Stir Plate)

Areas i have identified as improvements are:

Better SG Data Collection

- Looking to invest in a refractometer and an iSpindel (currently only have a hydrometer)

pH Measurements (currently i dont measure pH during brewing)

Short Term - Test Strips (Harris or ColorpHast)

Medium Term - pH Instrument (Chinese)

Long Term - pH Instrument (Hanna Ins)

Mash pH correction (Lactic Acid / Calcium Carbonate)

Wort Dissolved O2 Forced Addition (Wort Aeration Pump + Airstone etc)

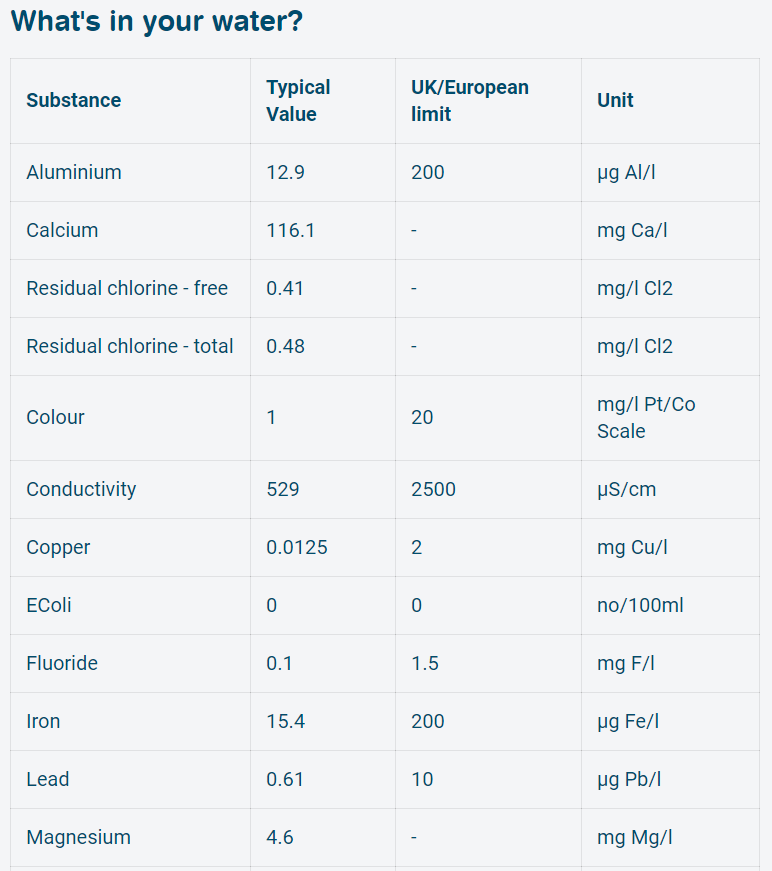

Brewing Water (currently treat with Campden tablet to remove chlorine)

Medium Term - Carbon Filter

Long Term - RODI + Brew Salts

What should be my priority in the above ?

I currently partial mash on a gas hob so the obvious area of improvement is to go Electric (so i have stricter Mash temperature control) and All Grain.

However that is also a big investment so while this is a longer term goal, i am looking at other areas of improvement i can make in the mean time.

My improvements so far have centered around Yeast viability/health, so i focused on:

Fermentation Temp Control (invested in DIY Temp Controlled Fridge)

Yeast Re-hydration (if using dry)

Yeast Storage (if using liquid)

Yeast Nutrient (end of boil)

Yeast Starter (invested in Erlenmeyer Flask + Magnetic Stir Plate)

Areas i have identified as improvements are:

Better SG Data Collection

- Looking to invest in a refractometer and an iSpindel (currently only have a hydrometer)

pH Measurements (currently i dont measure pH during brewing)

Short Term - Test Strips (Harris or ColorpHast)

Medium Term - pH Instrument (Chinese)

Long Term - pH Instrument (Hanna Ins)

Mash pH correction (Lactic Acid / Calcium Carbonate)

Wort Dissolved O2 Forced Addition (Wort Aeration Pump + Airstone etc)

Brewing Water (currently treat with Campden tablet to remove chlorine)

Medium Term - Carbon Filter

Long Term - RODI + Brew Salts

What should be my priority in the above ?

![Craft A Brew - Safale BE-256 Yeast - Fermentis - Belgian Ale Dry Yeast - For Belgian & Strong Ales - Ingredients for Home Brewing - Beer Making Supplies - [3 Pack]](https://m.media-amazon.com/images/I/51bcKEwQmWL._SL500_.jpg)