- Joined

- Aug 8, 2017

- Messages

- 1,509

- Reaction score

- 1,783

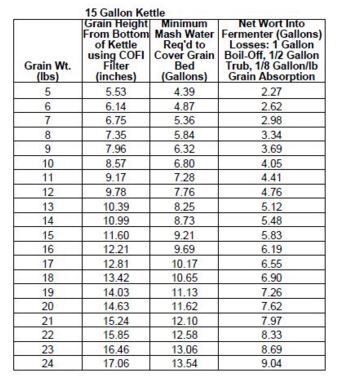

Hey everyone I was trying to get some insight on brewing large gravity beers using the 15gal Brew Boss system with COFI filter. I typically brew 5.5 gal batches. I am learning one of the challenges with BIAB is high gravity beers over 1.080 and up. I recently did a Scotch Ale 1.079 and ended up a 1.063. Beer should have been 7.3% ended up 5.5%.

One of the main reasons for me purchasing the B.B. system was consistency. I plan to perfect a few beers to my liking, so consistency is key. I am considering splitting up my mash in half and combine into one boil? Or, add more water volume during the mash and boil longer. Or, hold back a gal or two and perform a sparge over the COFI to rinse the grain?

What are other B.B. users doing for larger 8-10% beers?

One of the main reasons for me purchasing the B.B. system was consistency. I plan to perfect a few beers to my liking, so consistency is key. I am considering splitting up my mash in half and combine into one boil? Or, add more water volume during the mash and boil longer. Or, hold back a gal or two and perform a sparge over the COFI to rinse the grain?

What are other B.B. users doing for larger 8-10% beers?

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)