I have a 120V/20A system i put together myself. It has worked well for probably 5 or 6 brews. Last brew, the breaker switch on my control box started tripping and shutting everything off. It would just do this at random, a few times during the ramp up to mash, a few times during the ramp up to boil. It also shut off during boil multiple times, with the power dialed at 85-90%. I can turn it back on after a few minutes, then it's fine for a while and then shuts off again (that was an annoying brew day)

the switch is rated 20Amps. I am using a 2250 element from brew hardware. Nominally, that should pull 2250/120=18.6A from my 20Amp outlet. The only other thing pulling current would have been the PID, which should be in the mA.

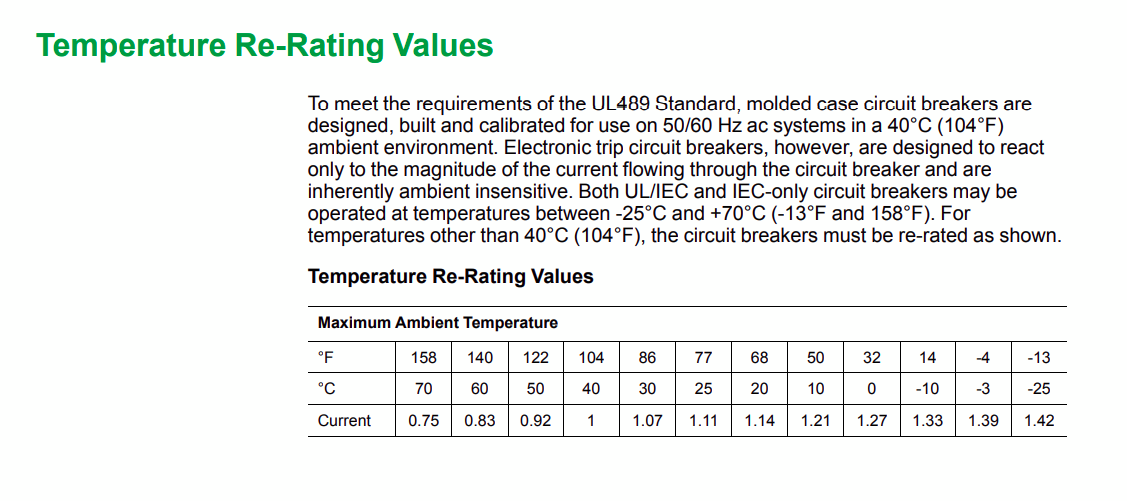

i measured the resistance of the element. 6.3-6.4 ohm. I measured the outlet output, came in at 124VAC. Now 124/6.3=19.7A is getting awefully close to 20A. But somehow this had not been an issue the last 5 times i brewed. I am aware others use this element on a 20A circuit and it seems that is what it is designed and marketed for.

Any thoughts on how to troubleshoot? Has the breaker switch become faulty? Or is this cutting it to close in terms of available power, but then what would be the point of selling this particular element?

the switch is rated 20Amps. I am using a 2250 element from brew hardware. Nominally, that should pull 2250/120=18.6A from my 20Amp outlet. The only other thing pulling current would have been the PID, which should be in the mA.

i measured the resistance of the element. 6.3-6.4 ohm. I measured the outlet output, came in at 124VAC. Now 124/6.3=19.7A is getting awefully close to 20A. But somehow this had not been an issue the last 5 times i brewed. I am aware others use this element on a 20A circuit and it seems that is what it is designed and marketed for.

Any thoughts on how to troubleshoot? Has the breaker switch become faulty? Or is this cutting it to close in terms of available power, but then what would be the point of selling this particular element?