My issues are many.

I use liquid yeast vials.

I do not make starters.

I do have a small Fermentation Chamber and temp control, probe taped to side and insulated from ambient.

I purchase thinking I’ll brew then Life interferes and suddenly I’m pitching a vial 8 weeks later; sometimes 5weeks.

First clove was intentional, I made a Hefeweizen. It was okay but not my thing.

Then I made an Octoberfest-style ale with a Kolsch yeast, 60°F fermentation, that had distinct clove. I thought, “well, it was another German yeast like the Hefe, maybe that’s why.”

Then I made a simple pale ale with US West Coast style liquid. Fermented at 65°, ramped to 68 for a few days after 2 weeks, took sample and it tasted like the Hefeweizen to me.

That’s when I read about under-pitching causing phenols, which can be clove (or medicinal or bandaid; neither of which this tastes like—it is simply clove). In both of these last two batches, the lag time prior to seeing the telltale exothermic fermentation was nearly 5 days.

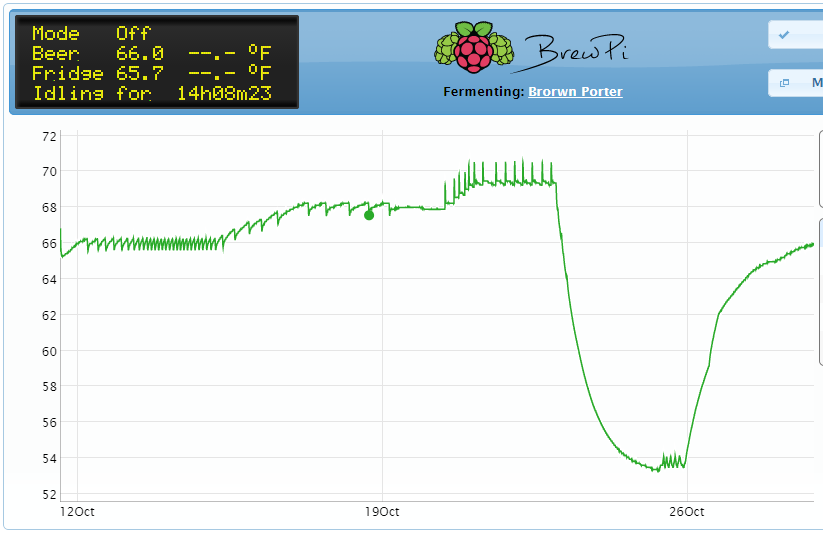

So my most recent was a Porter, and I tried making a starter, but the best laid plans of mice and men often go awry and the starter was only 7hrs old when I pitched. However, I saw the exothermic data within 24 hours, done in about 30 hours, ramped temp all the way to 70 over 3 days, held for 3, then to 50. Two weeks since brew day I took a gravity reading and it’s 1.021. I’m flummoxed. Extract and steeping grains. I sanitized a long spoon and stirred the sucker up and will look in a week.

This hobby is getting discouraging. But the data seems to point to:

a) Make a real starter, really in advance (just finished and tested stir plate)

b) Measure gravity 10 days in and react; just letting it go 2-3 weeks isn’t working for me on English strains

c) Screw the clarifying (rack to “bright tank”

– just ferment then bottle

d) Stop buying in advance. Older is only really good in antiques; not so good in yeast

e) Keep trying. Never give up. Never surrernder.

![Craft A Brew - Safale BE-256 Yeast - Fermentis - Belgian Ale Dry Yeast - For Belgian & Strong Ales - Ingredients for Home Brewing - Beer Making Supplies - [3 Pack]](https://m.media-amazon.com/images/I/51bcKEwQmWL._SL500_.jpg)