You don't need more that 6psi. I'm using the same product and works just fine. Spike compensated for the 6psi by using a more aggressive spray nozzle, for lack of a better term. That's discussed by Spike in the thread I linked above.It's hard to tell if you have any steam coming out of the lid when the condenser is operating - since you don't really show any video of the lid when the condenser is running.

But.....you shouldn't see any steam coming out of the lid when the condenser is on. If you do see steam coming out anywhere up-top, you don't have a vacuum pulling steam out of the kettle. The only place you should see steam is out of the condenser output tube into the bucket.

I question if your water pressure is high enough into the sprayer nozzle. In my homemade condenser, I can just disassemble it and watch the spray pattern to ensure it's high enough pressure. Can you do the same with your setup? I hook up household water to the condenser, which is probably in the 40psi range (but I do throttle it down some). I'd think you would need more than 6psi feeding the spray nozzle.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Boil kettle condenser - no overhead ventilation needed

- Thread starter BrunDog

- Start date

Help Support Homebrew Talk:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

Lots of posts, so here are my random musings:

1. I remain skeptical that 6 psi can truly atomize water. It may create a spray, but mixing and surface area are the name of the game. 40+ psi will give you fine droplets with an appropriate nozzle... Atomization is all about pressure differentials, so I'm just not sure about 6 psi being adequate - but I'm willing to be proven wrong.

2. You don't need to assess changes in boil volume - that is a long road. Just put the condenser lid flat on a surface (or slighty canted downhill) and turn it on. If any water falls below the center of the lid, then there is a problem as the spray nozzle is ejecting water back toward the lid.

3. @IanMC... does the temperature all when you remove the lid completely? It should, since a great deal of heat is leaving the vessel when open. With the lid on, all that heat is trapped. When the condenser is on, some of the heat is removed... so yes, if your power input is low (1800W is barely enough), then this will happen organically. I don't think I realized how little your available power input was, so this is likely the problem. From experience, for relative example, an open 15 gallon kettle needs 72% power when open and 30% power when sealed with an operating condenser. That is a BIG difference. I don't know the power required to maintain the boil when sealed with no operating condenser, but given the ~40% swing above, it is likely on the order or 15% or more.

1. I remain skeptical that 6 psi can truly atomize water. It may create a spray, but mixing and surface area are the name of the game. 40+ psi will give you fine droplets with an appropriate nozzle... Atomization is all about pressure differentials, so I'm just not sure about 6 psi being adequate - but I'm willing to be proven wrong.

2. You don't need to assess changes in boil volume - that is a long road. Just put the condenser lid flat on a surface (or slighty canted downhill) and turn it on. If any water falls below the center of the lid, then there is a problem as the spray nozzle is ejecting water back toward the lid.

3. @IanMC... does the temperature all when you remove the lid completely? It should, since a great deal of heat is leaving the vessel when open. With the lid on, all that heat is trapped. When the condenser is on, some of the heat is removed... so yes, if your power input is low (1800W is barely enough), then this will happen organically. I don't think I realized how little your available power input was, so this is likely the problem. From experience, for relative example, an open 15 gallon kettle needs 72% power when open and 30% power when sealed with an operating condenser. That is a BIG difference. I don't know the power required to maintain the boil when sealed with no operating condenser, but given the ~40% swing above, it is likely on the order or 15% or more.

Skeptonomicon

Member

- Joined

- Jan 19, 2020

- Messages

- 18

- Reaction score

- 10

I am not sure how this system works. Is the 6 PSI the pressure on the high side of the pump, or is 6 psi the vacuum in the boiling kettle? If it is the vacuum level, then you should be boiling at 12F lower temp than before (2F per psi change). It could be that you are getting a good seal, and drawing a vacuum, while others don't get the same seal, and have a much lower vacuum. Only a small vacuum is needed to scavenge the vapors, and the condensation works on the pumps output pressure, so would still work 100% with a leaky vessel. My first thought is that some folks may not be using the silicone gasket, or there is a rubber hole plug for the recirculating pump that was not designed to be air tight, but more as a dust cover, and this prevents drawing a vacuum.

rkhanso

Well-Known Member

- Joined

- Jan 24, 2017

- Messages

- 785

- Reaction score

- 178

How I understand this......

You should see steam escaping the lid or port on the lid when boiling but the condenser is not spraying (off). Old-school boil with steam.

When the condenser is spraying water (in use), if there is no steam escaping the lid area or any port on the lid, then you have a vacuum and the condenser is operating OK from a "pulling vacuum" perspective. The exiting water should be hot or warm (depending on volume of water used in the condenser spray).

If you have steam escaping the lid area when boiling wort and the condenser is on, then there's no vacuum and problem with the condenser or a big leak in the lid area. Check the condenser output to make sure it's not under water in the bucket, plugged, or has an uphill slope anywhere on it (think P-Trap).

If you pull a vacuum (boiling and no steam from the kettle lid area - Condenser working OK) but your wort increases in volume, cools off or even stops boiling (and maybe you've not even yet turned the heat source down to compensate for the compressor being used), the only thing that can cause that is cold water entering the kettle through the condenser port. If you have this situation, maybe adding a super-short nipple between the condenser top elbow and the spray nozzle would help by getting the spray a little lower in the tube and not prone to flow down into the lid and cool the wort. I'm not sure how far you could go down past the horizontal "tee" portion and still have the condenser work like it should.

I still think it's worth hooking up the pump to the spray nozzle with it outside the condenser tube and take a look at the spray pattern. It should be a fine atomized mist. My guess is it may not be.

My homemade condenser (Thanks BrunDog for the example) uses less than $.05 of water on a brew day. I'll take that with the ease of not having to keep filling a bucket and then pay $.05 to run a pump.

You should see steam escaping the lid or port on the lid when boiling but the condenser is not spraying (off). Old-school boil with steam.

When the condenser is spraying water (in use), if there is no steam escaping the lid area or any port on the lid, then you have a vacuum and the condenser is operating OK from a "pulling vacuum" perspective. The exiting water should be hot or warm (depending on volume of water used in the condenser spray).

If you have steam escaping the lid area when boiling wort and the condenser is on, then there's no vacuum and problem with the condenser or a big leak in the lid area. Check the condenser output to make sure it's not under water in the bucket, plugged, or has an uphill slope anywhere on it (think P-Trap).

If you pull a vacuum (boiling and no steam from the kettle lid area - Condenser working OK) but your wort increases in volume, cools off or even stops boiling (and maybe you've not even yet turned the heat source down to compensate for the compressor being used), the only thing that can cause that is cold water entering the kettle through the condenser port. If you have this situation, maybe adding a super-short nipple between the condenser top elbow and the spray nozzle would help by getting the spray a little lower in the tube and not prone to flow down into the lid and cool the wort. I'm not sure how far you could go down past the horizontal "tee" portion and still have the condenser work like it should.

I still think it's worth hooking up the pump to the spray nozzle with it outside the condenser tube and take a look at the spray pattern. It should be a fine atomized mist. My guess is it may not be.

My homemade condenser (Thanks BrunDog for the example) uses less than $.05 of water on a brew day. I'll take that with the ease of not having to keep filling a bucket and then pay $.05 to run a pump.

Last edited:

Hi all,

I did another test today. 5 gallons of water, condenser lid on but sprayer off, heated to a boil. Then, I took off the lid, and..... it dropped, down to at least 203 before I stopped the test. Well, it looks like my burner isn't putting out enough heat to maintain a boil with the lid off, which also fits well with Spike's theory that the entrapped steam may be necessary to maintain the boil I was seeing before.

Why didn't I notice this before? Because this current setup is fairly new, and previously I was using a different pot that had Refletix insulation. I've brewed with this setup since I got the new pot, but I typically have left the lid on until the boil was reached, then removed it, and I suppose I wasn't actually checking the temperature to confirm it from that point on. There was always still evolution of steam bubbles and the wort moving around a bit, I just didn't realize that it wasn't actually at true boiling temp. It still made beer, though. Also, I have no doubt that a bit of insulation on this pot would also give me the few extra degrees I need to keep a vigorous boil going with the steam condenser running. But, I really don't like the insulation, and given that I'm just barely reaching my goal anyway, I think it's time to graduate to a higher wattage induction cooktop. I just need to wire a 240v outlet in my garage first...

Also, for those of you who asked what the spray pattern coming out of the Spike nozzle is like, behold: Spray pattern video. Apologies for the portrait aspect ratio.

Does this look at all like the spray on your high PSI nozzles?

Thanks to everyone who helped me get to this point. I appreciate your great suggestions and experience!

I did another test today. 5 gallons of water, condenser lid on but sprayer off, heated to a boil. Then, I took off the lid, and..... it dropped, down to at least 203 before I stopped the test. Well, it looks like my burner isn't putting out enough heat to maintain a boil with the lid off, which also fits well with Spike's theory that the entrapped steam may be necessary to maintain the boil I was seeing before.

Why didn't I notice this before? Because this current setup is fairly new, and previously I was using a different pot that had Refletix insulation. I've brewed with this setup since I got the new pot, but I typically have left the lid on until the boil was reached, then removed it, and I suppose I wasn't actually checking the temperature to confirm it from that point on. There was always still evolution of steam bubbles and the wort moving around a bit, I just didn't realize that it wasn't actually at true boiling temp. It still made beer, though. Also, I have no doubt that a bit of insulation on this pot would also give me the few extra degrees I need to keep a vigorous boil going with the steam condenser running. But, I really don't like the insulation, and given that I'm just barely reaching my goal anyway, I think it's time to graduate to a higher wattage induction cooktop. I just need to wire a 240v outlet in my garage first...

Also, for those of you who asked what the spray pattern coming out of the Spike nozzle is like, behold: Spray pattern video. Apologies for the portrait aspect ratio.

Does this look at all like the spray on your high PSI nozzles?

Thanks to everyone who helped me get to this point. I appreciate your great suggestions and experience!

Last edited:

I was thinking of using an induction cooktop once until I saw the price for the wattage I would need. That looks like a good enough spray.Hi all,

I did another test today. 5 gallons of water, condenser lid on but sprayer off, heated to a boil. Then, I took off the lid, and..... it dropped, down to at least 203 before I stopped the test. Well, it looks like my burner isn't putting out enough heat to maintain a boil with the lid off, which also fits well with Spike's theory that the entrapped steam may be necessary to maintain the boil I was seeing before.

Why didn't I notice this before? Because this current setup is fairly new, and previously I was using a different pot that had Refletix insulation. I've brewed with this setup since I got the new pot, but I typically have left the lid on until the boil was reached, then removed it, and I suppose I wasn't actually checking the temperature to confirm it from that point on. There was always still evolution of steam bubbles and the wort moving around a bit, I just didn't realize that it wasn't actually at true boiling temp. It still made beer, though. Also, I have no doubt that a bit of insulation on this pot would also give me the few extra degrees I need to keep a vigorous boil going with the steam condenser running. But, I really don't like the insulation, and given that I'm just barely reaching my goal anyway, I think it's time to graduate to a higher wattage induction cooktop. I just need to wire a 240v outlet in my garage first...

Also, for those of you who asked what the spray pattern coming out of the Spike nozzle is like, behold: Spray pattern video. Apologies for the portrait aspect ratio.

Does this look at all like the spray on your high PSI nozzles?

Thanks to everyone who helped me get to this point. I appreciate your great suggestions and experience!

$20.94

$29.99

The Brew Your Own Big Book of Clone Recipes: Featuring 300 Homebrew Recipes from Your Favorite Breweries

Amazon.com

$53.24

1pc Hose Barb/MFL 1.5" Tri Clamp to Ball Lock Post Liquid Gas Homebrew Kegging Fermentation Parts Brewer Hardware SUS304(Liquid Hose Barb)

Guangshui Weilu You Trading Co., Ltd

$33.99 ($17.00 / Count)

$41.99 ($21.00 / Count)

2 Pack 1 Gallon Large Fermentation Jars with 3 Airlocks and 2 SCREW Lids(100% Airtight Heavy Duty Lid w Silicone) - Wide Mouth Glass Jars w Scale Mark - Pickle Jars for Sauerkraut, Sourdough Starter

Qianfenie Direct

$22.00 ($623.23 / Ounce)

AMZLMPKNTW Ball Lock Sample Faucet 30cm Reinforced Silicone Hose Secondary Fermentation Homebrew Kegging joyful

无为中南商贸有限公司

$7.79 ($7.79 / Count)

Craft A Brew - LalBrew Voss™ - Kveik Ale Yeast - For Craft Lagers - Ingredients for Home Brewing - Beer Making Supplies - (1 Pack)

Craft a Brew

$10.99 ($31.16 / Ounce)

Hornindal Kveik Yeast for Homebrewing - Mead, Cider, Wine, Beer - 10g Packet - Saccharomyces Cerevisiae - Sold by Shadowhive.com

Shadowhive

$58.16

HUIZHUGS Brewing Equipment Keg Ball Lock Faucet 30cm Reinforced Silicone Hose Secondary Fermentation Homebrew Kegging Brewing Equipment

xiangshuizhenzhanglingfengshop

$176.97

1pc Commercial Keg Manifold 2" Tri Clamp,Ball Lock Tapping Head,Pressure Gauge/Adjustable PRV for Kegging,Fermentation Control

hanhanbaihuoxiaoshoudian

$53.24

1pc Hose Barb/MFL 1.5" Tri Clamp to Ball Lock Post Liquid Gas Homebrew Kegging Fermentation Parts Brewer Hardware SUS304(Liquid MFL)

yunchengshiyanhuqucuichendianzishangwuyouxiangongsi

rkhanso

Well-Known Member

- Joined

- Jan 24, 2017

- Messages

- 785

- Reaction score

- 178

My spray pattern is more of a "fog" or "mist".

Yours looks more like a hand-held garden sprayer on a wide pattern.

I'm not sure if that would cause issues, however.

But it does look different than mine.

Yours looks more like a hand-held garden sprayer on a wide pattern.

I'm not sure if that would cause issues, however.

But it does look different than mine.

Frudel

Member

- Joined

- Sep 29, 2016

- Messages

- 7

- Reaction score

- 2

Hello , i found this thread while i was searching for a Condenser for beerbrewing and i decided to build it

and not buy it.

I got all the part needed for the project but McMaster-Carr would not or can ship the nozzles to germany.

"Thank you for considering McMaster-Carr for your purchase, but we do not accept your orders due to the cost of complying with US export regulations. We have therefore cancelled your order. I am sorry we cannot help you further. "

If the post above is not allowed pls delete it .

I never heard that there are US export regulation to germany for misting nozzles....

Have you any idea how to get 3 nozzles to germany or are there substitutes that could be shipped to germany ?

I love that forum and the work you all do. * BrunDog thanks for the inspiration.

Sorry my english is very rusty ......

Greetings form germany

Markus

and not buy it.

I got all the part needed for the project but McMaster-Carr would not or can ship the nozzles to germany.

"Thank you for considering McMaster-Carr for your purchase, but we do not accept your orders due to the cost of complying with US export regulations. We have therefore cancelled your order. I am sorry we cannot help you further. "

If the post above is not allowed pls delete it .

I never heard that there are US export regulation to germany for misting nozzles....

Have you any idea how to get 3 nozzles to germany or are there substitutes that could be shipped to germany ?

I love that forum and the work you all do. * BrunDog thanks for the inspiration.

Sorry my english is very rusty ......

Greetings form germany

Markus

AntoineLeclair

Member

- Joined

- Jul 19, 2020

- Messages

- 10

- Reaction score

- 5

Hi Frudel,

I had the same problem as you, living in Canada.

I'm in the process of building one myself. I'm almost done. I just have to test things this week, and fix what needs to be fixed.

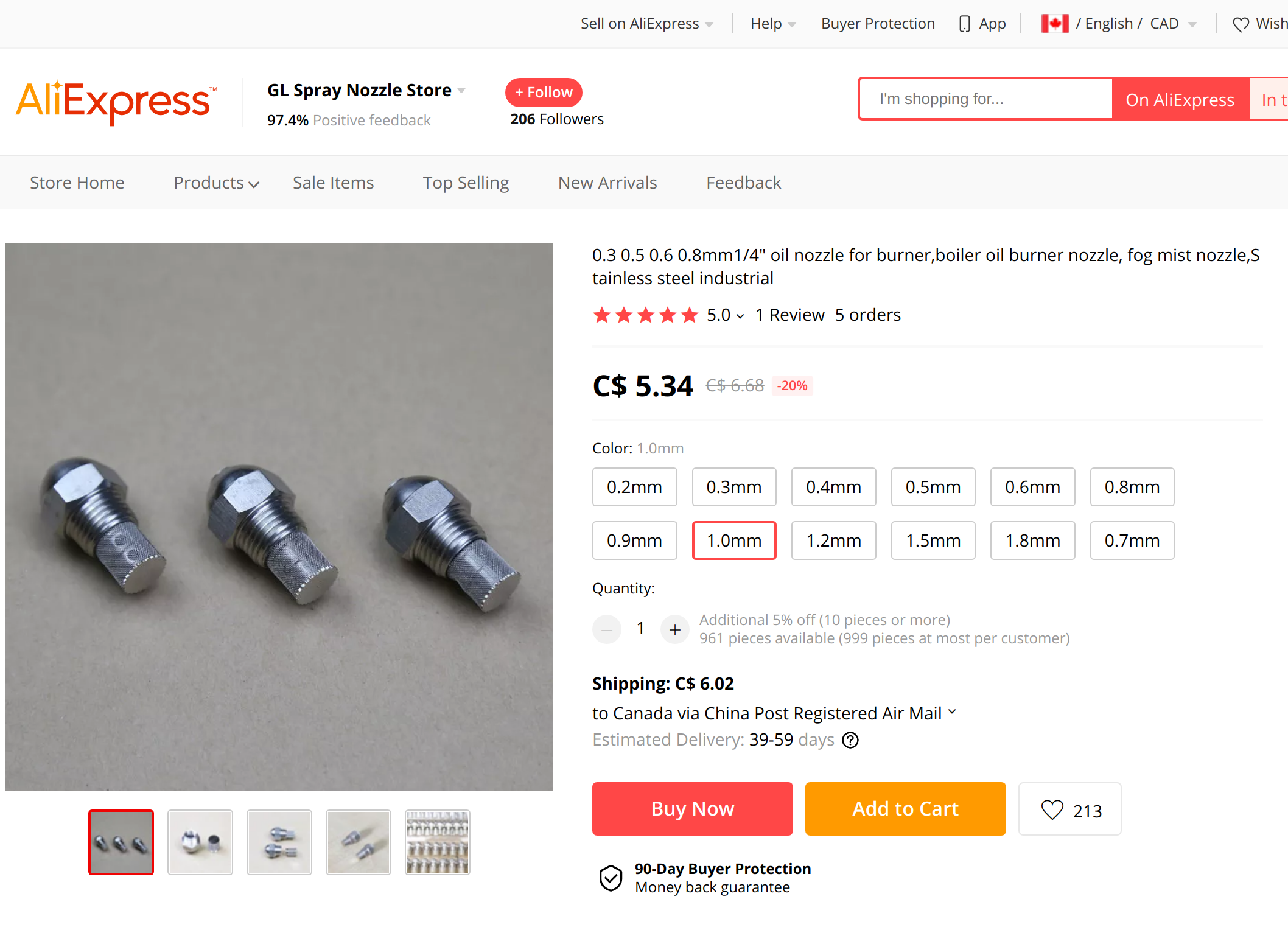

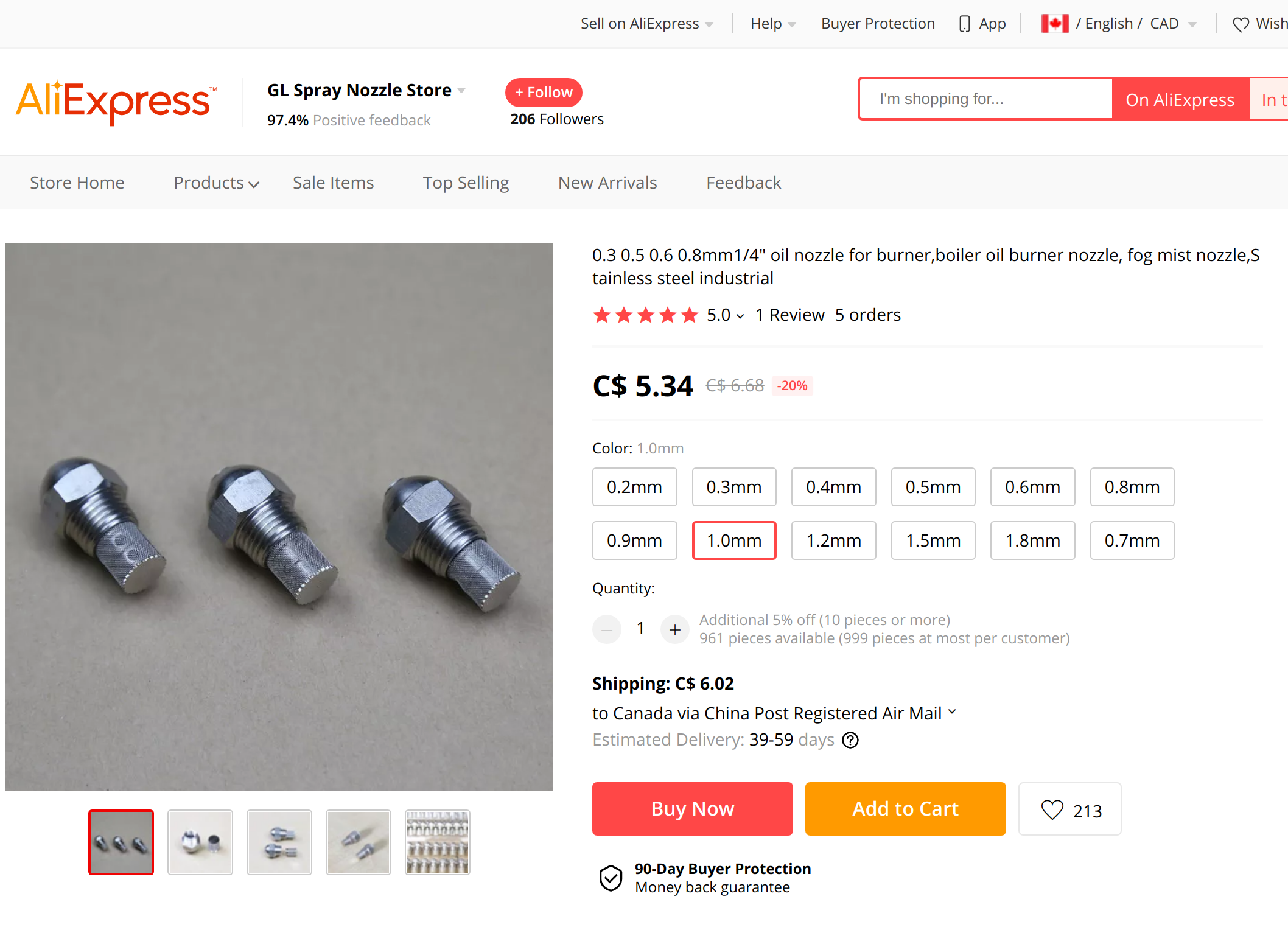

I used a nozzle from Aliexpress. It's using BSP threads, so you'll need BSP reducers, tri clamp adapters, etc.

https://www.aliexpress.com/item/32790032084.html

And here's a screenshot for people from the future finding a dead link:

It's a long process, since every time I need to buy parts to move the project forward, I have to wait ~2 months. For example, I bought the 1.0mm, but after testing it yesterday, I realize that I may need the 0.9mm one.

I had the same problem as you, living in Canada.

I'm in the process of building one myself. I'm almost done. I just have to test things this week, and fix what needs to be fixed.

I used a nozzle from Aliexpress. It's using BSP threads, so you'll need BSP reducers, tri clamp adapters, etc.

https://www.aliexpress.com/item/32790032084.html

And here's a screenshot for people from the future finding a dead link:

It's a long process, since every time I need to buy parts to move the project forward, I have to wait ~2 months. For example, I bought the 1.0mm, but after testing it yesterday, I realize that I may need the 0.9mm one.

Frudel

Member

- Joined

- Sep 29, 2016

- Messages

- 7

- Reaction score

- 2

They are for oil , its not easy to find the diameter / flowrate that fits . different viscosity.

Thats the problem with ali at last 1 month to wait for testing - let me know if the 0.9 one is ok.

What flow rate to you need or want to have gph ?

Angel 60° works?

Thats the problem with ali at last 1 month to wait for testing - let me know if the 0.9 one is ok.

What flow rate to you need or want to have gph ?

Angel 60° works?

It's not that there are restrictions on exporting nozzles from the USA. If you export anything technology related, then you have to prove compliance with all of the USA's export requirements. This is a giant paperwork and personnel training pita. You need a big export market to make the compliance overhead worthwhile. Apparently McMaster-Carr has decided that it is not worth the time and effort to put a compliance program in place, for the amount of foreign sales they would get.Hello , i found this thread while i was searching for a Condenser for beerbrewing and i decided to build it

and not buy it.

I got all the part needed for the project but McMaster-Carr would not or can ship the nozzles to germany.

"Thank you for considering McMaster-Carr for your purchase, but we do not accept your orders due to the cost of complying with US export regulations. We have therefore cancelled your order. I am sorry we cannot help you further. "

If the post above is not allowed pls delete it .

I never heard that there are US export regulation to germany for misting nozzles....

Have you any idea how to get 3 nozzles to germany or are there substitutes that could be shipped to germany ?

I love that forum and the work you all do. * BrunDog thanks for the inspiration.

Sorry my english is very rusty ......

Greetings form germany

Markus

Brew on

AntoineLeclair

Member

- Joined

- Jul 19, 2020

- Messages

- 10

- Reaction score

- 5

They are for oil

I know, but it seems to do what it should do so far. I did not have time to test in the actual steam condenser setup yet, but I think it will work.

What flow rate to you need or want to have gph ?

The 1.0mm is spraying at a rate of 60 liters/hour (13.2 gph) for me. But I think it depends on the pressure of your water. I don't know the pressure of the water where I'm going to use it. I thought it was on the low side, so I went for 1.0mm, but I may have overshot. I think the goal should be to go as low as possible while still catching all the steam. From what I read, probably somewhere between 20 liters/hour to 70 liters/hour (5-15 gph).

Angel 60° works?

We'll see how it goes, but that's my hope. I'm using it inside a 1.5" triclamp tube (vs 2" or bigger), so I'd rather have a narrower angle than wider. I think 60° should be fine, but I still have to confirm.

What are the specs on the nozzle you need?Hello , i found this thread while i was searching for a Condenser for beerbrewing and i decided to build it

and not buy it.

I got all the part needed for the project but McMaster-Carr would not or can ship the nozzles to germany.

"Thank you for considering McMaster-Carr for your purchase, but we do not accept your orders due to the cost of complying with US export regulations. We have therefore cancelled your order. I am sorry we cannot help you further. "

If the post above is not allowed pls delete it .

I never heard that there are US export regulation to germany for misting nozzles....

Have you any idea how to get 3 nozzles to germany or are there substitutes that could be shipped to germany ?

I love that forum and the work you all do. * BrunDog thanks for the inspiration.

Sorry my english is very rusty ......

Greetings form germany

Markus

Charlie139

Member

- Joined

- Mar 29, 2020

- Messages

- 10

- Reaction score

- 2

I bought mine from Qingdao China. I live 90 minutes away. If you’re interested I can query the guy that sold them to me to see if he would ship to Europe...payment can be problematic. My wife handled the payment and shipping details and the nozzle works well. Let me know if you’re interested...

Attachments

Frudel

Member

- Joined

- Sep 29, 2016

- Messages

- 7

- Reaction score

- 2

I bought mine from Qingdao China. I live 90 minutes away. If you’re interested I can query the guy that sold them to me to see if he would ship to Europe...payment can be problematic. My wife handled the payment and shipping details and the nozzle works well. Let me know if you’re interested...

Thank you for that offer - i ordered differned burner nozzles for test with my water pressure to prevent a pressure reducer .

I guess the frog / mist will be better with a higher pressure.

I forgott about BT , you are right , they have different with suitable flow rates . Post comes too late will order one , when i buy again from

Maltmiller.

Great Help ! Very kind !

AntoineLeclair

Member

- Joined

- Jul 19, 2020

- Messages

- 10

- Reaction score

- 5

I'll post with more details eventually, but I just wanted to confirm that the nozzle I ordered from Aliexpress worked perfectly. The link + screenshot are in a previous post, a few days ago. As I thought, it's using a bit too much water for my taste, but it does the job perfectly. The water came out at 40°C (104°F). The steam stops escaping from the lid as soon as I turn the water on.

brewers droop

Member

- Joined

- Nov 24, 2020

- Messages

- 11

- Reaction score

- 8

Are you using a flat kettle lid or a domed lid? i am looking at building my own condenser for a 200ltr kettle,as my current application needs changing

AntoineLeclair

Member

- Joined

- Jul 19, 2020

- Messages

- 10

- Reaction score

- 5

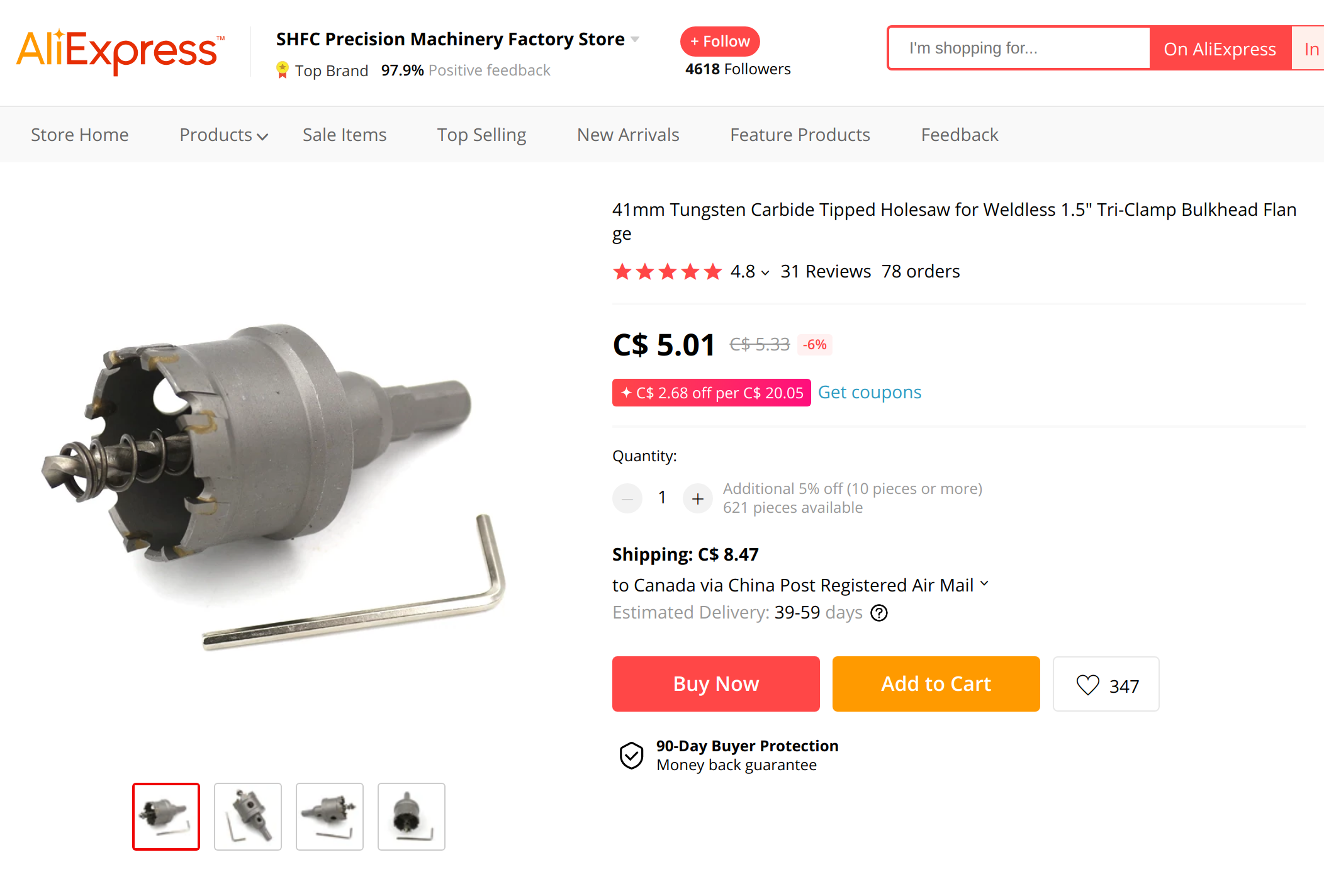

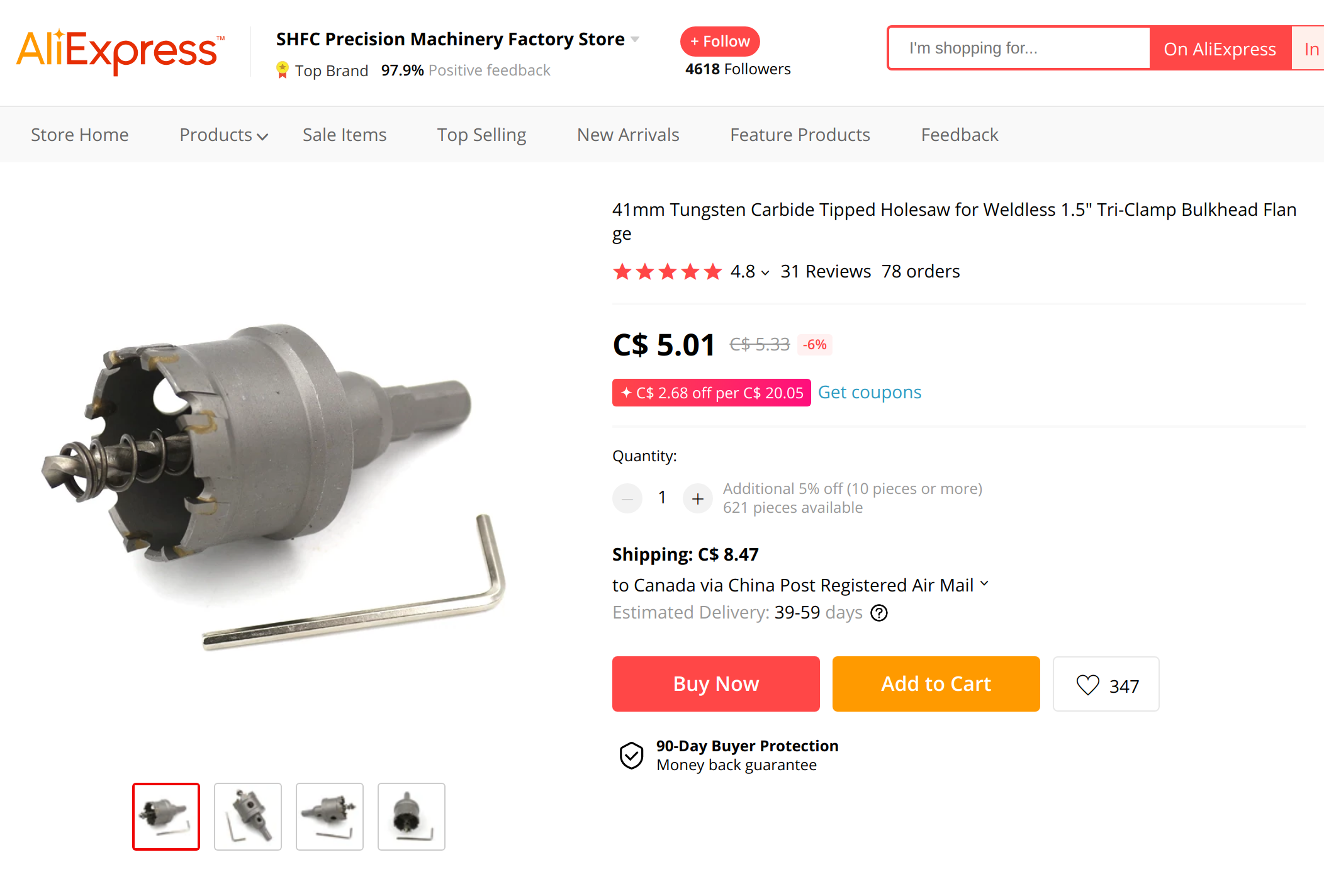

I drilled a hole in the lid and installed a weldless triclamp ferrule.

Here's the ferrule: US $8.45 6% OFF|Weldless Bulkehad 1.5

and the drill bit US $3.75 6% OFF|41mm Tungsten Carbide Tipped Holesaw for Weldless 1.5

Here's the ferrule: US $8.45 6% OFF|Weldless Bulkehad 1.5

and the drill bit US $3.75 6% OFF|41mm Tungsten Carbide Tipped Holesaw for Weldless 1.5

Are you using a flat kettle lid or a domed lid? i am looking at building my own condenser for a 200ltr kettle,as my current application needs changing

The lid on my kettle is slightly curved so the condenser does sit quite square to the kettle. It's more of an OCD thing.

EDIT - that should have been "doesn't sit quite square to the kettle."

Last edited:

brewers droop

Member

- Joined

- Nov 24, 2020

- Messages

- 11

- Reaction score

- 8

Just looking at nozzles online, the few i have are not cone, my water flow rate is 7second per ltr, is this around the same as most? Obviously i want to use less water as possible.

brewers droop

Member

- Joined

- Nov 24, 2020

- Messages

- 11

- Reaction score

- 8

Yes my kettle lid already has the centre triclamp fitting for my CIP,but i want to keep this contraption small, and as you say my lid is also curved downwards so will have a slight angle on the pipework. I am worried that 1.5 inch is not going to be big enough on a 200ltr pot.The lid on my kettle is slightly curved so the condenser does sit quite square to the kettle. It's more of an OCD thing.

Oh nice! Another Chinese company exactly cloning my fitting design.

AntoineLeclair

Member

- Joined

- Jul 19, 2020

- Messages

- 10

- Reaction score

- 5

Oh nice! Another Chinese company exactly cloning my fitting design.

Are you talking about the tri clamp weldless bulkhead fitting? If so, that sucks.

It also looks pretty much like the one on the site of SS Brewtech.

brewers droop

Member

- Joined

- Nov 24, 2020

- Messages

- 11

- Reaction score

- 8

Who is cloning your design? I buy nothing from China, i source all my 304 from uk engineering, if i cant buy it, i have it manufactured locally.Oh nice! Another Chinese company exactly cloning my fitting design.

Are you talking about the tri clamp weldless bulkhead fitting? If so, that sucks.

It also looks pretty much like the one on the site of SS Brewtech.

Yeah, guess where SS got that design. They straight up cloned mine.

I have a 27 gal kettle with a slightly curved lid. I purchased the 1.5 inch kit from Brewhardware with the 9 gal/hr nozzle and it works great. I would assume that bobby's 2 inch kit would work fine for your 200 ltr (52 gal) kettle. I wouldn't be surprised if the 1.5 inch wouldn't do the job. I get no DMS in my finished beers even my lighter lagers.Yes my kettle lid already has the centre triclamp fitting for my CIP,but i want to keep this contraption small, and as you say my lid is also curved downwards so will have a slight angle on the pipework. I am worried that 1.5 inch is not going to be big enough on a 200ltr pot.

Prost

Did you have a patent?Yeah, guess where SS got that design. They straight up cloned mine.

It is I, LeClair. A great line from the British sitcom Allo Allo.I'll post with more details eventually, but I just wanted to confirm that the nozzle I ordered from Aliexpress worked perfectly. The link + screenshot are in a previous post, a few days ago. As I thought, it's using a bit too much water for my taste, but it does the job perfectly. The water came out at 40°C (104°F). The steam stops escaping from the lid as soon as I turn the water on.

Similar threads

- Replies

- 2

- Views

- 913

- Replies

- 1

- Views

- 571

- Replies

- 11

- Views

- 1K

![Craft A Brew - Safale BE-256 Yeast - Fermentis - Belgian Ale Dry Yeast - For Belgian & Strong Ales - Ingredients for Home Brewing - Beer Making Supplies - [3 Pack]](https://m.media-amazon.com/images/I/51bcKEwQmWL._SL500_.jpg)