I honestly don't think it is that critical. Ideally, you would like the spray cone to land just below the entrance to the tee to prevent that water from spraying back into your kettle. But a inch or two deeper will not any difference in terms of performance.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Boil kettle condenser - no overhead ventilation needed

- Thread starter BrunDog

- Start date

Help Support Homebrew Talk:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

My boil off rate is lower but it was expected. What is less cool, is the fact that tap water (of the nozzle) may flow back to the boiler.

I do not know if my original post was clear. The only issue is not steam related. When tested in the early stage of the boiling process, part of the sprinkled water seemed to flow back to the boiler, thus questioning the nozzle position.

But you also asked if it would flow back when under steam pressure, which is what my response was directed to. You said you couldn't tell when full of steam; my comments were to suggest a way to determine whether there is flowback when under steam.

With steam or without, if the sprayer sprays into the inlet tube, it is too high.

As I was reading this entire thread yesterday (thank you all! this will be part of my future build at home) I noted with interest the comments about the temperature of the discharge relative to the rating of the drain pipes it's going to. This morning Facebook reminded me of a post I made there two years ago on this subject, thus reminding me where to find this picture.

The severely bent PVC pipes pictured below are from the bottom of a three bay sink in a brewery I worked for. I was called in to re-plumb the sink drains. They directed the discharge from their plate chiller into one bay of the sink and failed to add any cold water flow to temper the discharge to a level safe for the pipes. There was around 150 feet of damaged pipe throughout the building. This was a 3 barrel brew house.

It started as sagging wherever the pipe was poorly supported. Eventually those sags grew heavier with trapped hot water and the sagging accelerated. Then glue joints began to fail. The landlord installed new pipe on a shorter path to the drain, not because anyone noticed the sagging (as far as I know, nobody but me has noticed to this day), they did it to stop the flooding every time the glue failed in the tenant space next door. Soon the new pipe path was sagging too.

If your condenser is discharging at temps above the 140°F rating for PVC pipe, please consider increasing spray rate or adding cold water to temper the discharge below 140°F. You don't want the expense of replacing all the pipe in your walls or under the floor.

Someone here noted that we don't worry about pouring the boiling water from a pot of spaghetti down the sink. True enough. But that pot of spaghetti water quickly runs down the drain and contact time with any one spot in the pipe is relatively low. With the condenser discharge, the volume may be low, but the contact time is high.

One other note, you really shouldn't connect the discharge hose directly to any pipe, or even the side of a sink. There should be an air gap so contaminants can't back up into your boil kettle. I agree that most of what's been posted here would never be an issue, but some of the hard pipe connections certainly could be.

The severely bent PVC pipes pictured below are from the bottom of a three bay sink in a brewery I worked for. I was called in to re-plumb the sink drains. They directed the discharge from their plate chiller into one bay of the sink and failed to add any cold water flow to temper the discharge to a level safe for the pipes. There was around 150 feet of damaged pipe throughout the building. This was a 3 barrel brew house.

It started as sagging wherever the pipe was poorly supported. Eventually those sags grew heavier with trapped hot water and the sagging accelerated. Then glue joints began to fail. The landlord installed new pipe on a shorter path to the drain, not because anyone noticed the sagging (as far as I know, nobody but me has noticed to this day), they did it to stop the flooding every time the glue failed in the tenant space next door. Soon the new pipe path was sagging too.

If your condenser is discharging at temps above the 140°F rating for PVC pipe, please consider increasing spray rate or adding cold water to temper the discharge below 140°F. You don't want the expense of replacing all the pipe in your walls or under the floor.

Someone here noted that we don't worry about pouring the boiling water from a pot of spaghetti down the sink. True enough. But that pot of spaghetti water quickly runs down the drain and contact time with any one spot in the pipe is relatively low. With the condenser discharge, the volume may be low, but the contact time is high.

One other note, you really shouldn't connect the discharge hose directly to any pipe, or even the side of a sink. There should be an air gap so contaminants can't back up into your boil kettle. I agree that most of what's been posted here would never be an issue, but some of the hard pipe connections certainly could be.

Derry

Member

With steam or without, if the sprayer sprays into the inlet tube, it is too high.

Correct.

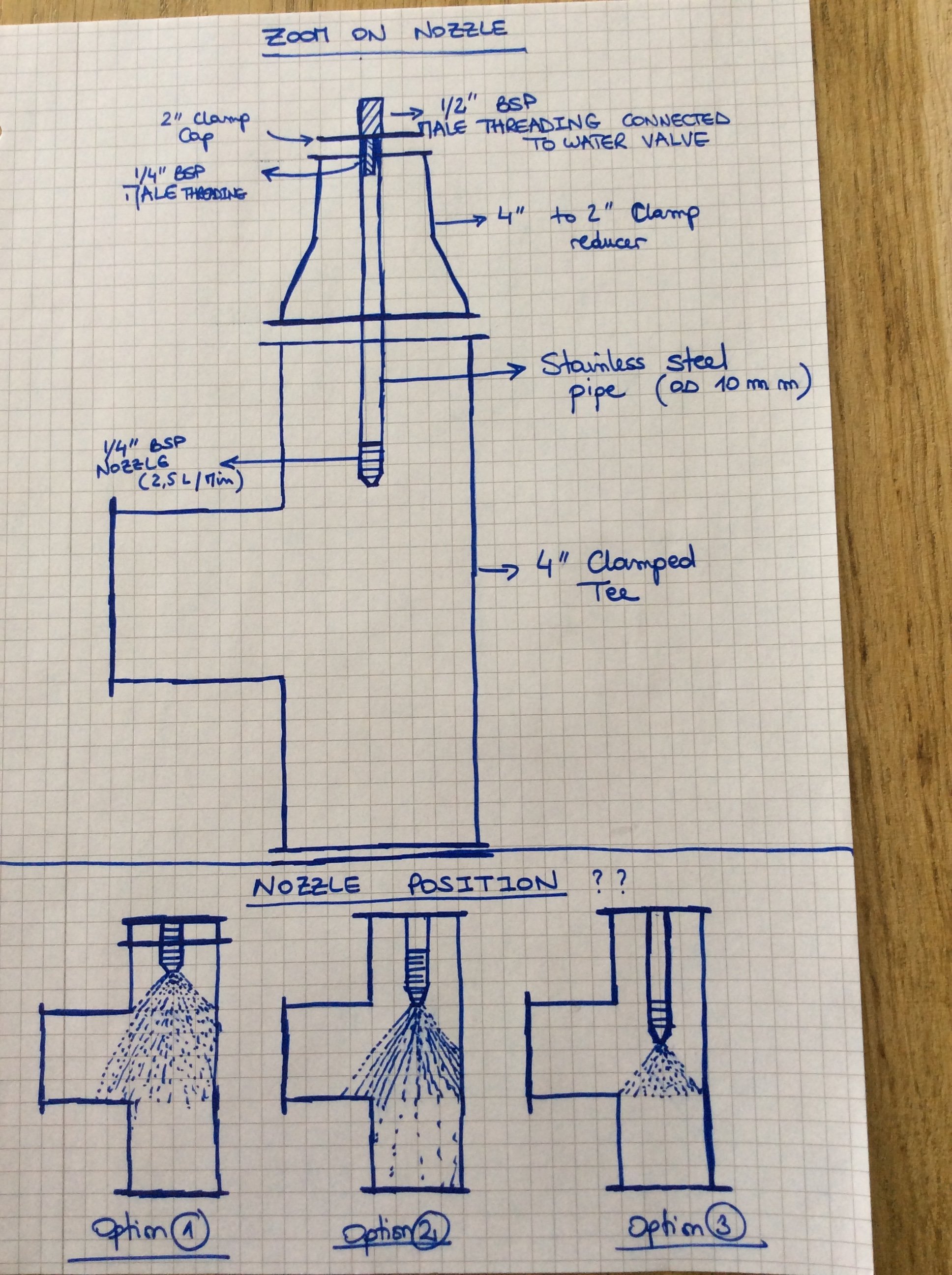

I did some sketches that enabled me to understand my mistake.

You may find below the boiler tank and condenser overall sketch as well as a detailed one of the condenser + nozzle position.

I initially went for a 90° full cone nozzle and installed it 2 inches upper the tee inlet, therefore option 1 in the above sketch. As you may see it, it is simply mathematical that it would spray in the inlet tube. ugh!

Ideal option is option 3, but I am afraid it won’t be efficient in my 4” setting. A lot of steam will get through between inlet and nozzle.

In order to get it right, I need to go for option 3 but with a 60° cone nozzle. This way I will be able to position the nozzle just at the inlet of the tee and still yield option 3 optimal spraying result.

$33.99 ($17.00 / Count)

$41.99 ($21.00 / Count)

2 Pack 1 Gallon Large Fermentation Jars with 3 Airlocks and 2 SCREW Lids(100% Airtight Heavy Duty Lid w Silicone) - Wide Mouth Glass Jars w Scale Mark - Pickle Jars for Sauerkraut, Sourdough Starter

Qianfenie Direct

$176.97

1pc Commercial Keg Manifold 2" Tri Clamp,Ball Lock Tapping Head,Pressure Gauge/Adjustable PRV for Kegging,Fermentation Control

hanhanbaihuoxiaoshoudian

$53.24

1pc Hose Barb/MFL 1.5" Tri Clamp to Ball Lock Post Liquid Gas Homebrew Kegging Fermentation Parts Brewer Hardware SUS304(Liquid MFL)

yunchengshiyanhuqucuichendianzishangwuyouxiangongsi

$53.24

1pc Hose Barb/MFL 1.5" Tri Clamp to Ball Lock Post Liquid Gas Homebrew Kegging Fermentation Parts Brewer Hardware SUS304(Liquid Hose Barb)

Guangshui Weilu You Trading Co., Ltd

$20.94

$29.99

The Brew Your Own Big Book of Clone Recipes: Featuring 300 Homebrew Recipes from Your Favorite Breweries

Amazon.com

$22.00 ($623.23 / Ounce)

AMZLMPKNTW Ball Lock Sample Faucet 30cm Reinforced Silicone Hose Secondary Fermentation Homebrew Kegging joyful

无为中南商贸有限公司

$58.16

HUIZHUGS Brewing Equipment Keg Ball Lock Faucet 30cm Reinforced Silicone Hose Secondary Fermentation Homebrew Kegging Brewing Equipment

xiangshuizhenzhanglingfengshop

$10.99 ($31.16 / Ounce)

Hornindal Kveik Yeast for Homebrewing - Mead, Cider, Wine, Beer - 10g Packet - Saccharomyces Cerevisiae - Sold by Shadowhive.com

Shadowhive

$7.79 ($7.79 / Count)

Craft A Brew - LalBrew Voss™ - Kveik Ale Yeast - For Craft Lagers - Ingredients for Home Brewing - Beer Making Supplies - (1 Pack)

Craft a Brew

Gravitysucks

Well-Known Member

Correct.

I did some sketches that enabled me to understand my mistake.

You may find below the boiler tank and condenser overall sketch as well as a detailed one of the condenser + nozzle position.View attachment 623399 View attachment 623400

I initially went for a 90° full cone nozzle and installed it 2 inches upper the tee inlet, therefore option 1 in the above sketch. As you may see it, it is simply mathematical that it would spray in the inlet tube. ugh!

Ideal option is option 3, but I am afraid it won’t be efficient in my 4” setting. A lot of steam will get through between inlet and nozzle.

In order to get it right, I need to go for option 3 but with a 60° cone nozzle. This way I will be able to position the nozzle just at the inlet of the tee and still yield option 3 optimal spraying result.

If you look at the condensers used in large breweries you'll see the nozzles are mounted quite low in the discharge tube.

One other note, you really shouldn't connect the discharge hose directly to any pipe, or even the side of a sink. There should be an air gap so contaminants can't back up into your boil kettle. I agree that most of what's been posted here would never be an issue, but some of the hard pipe connections certainly could be.

Can you explain what you mean by an "Air gap?"

Correct.

I did some sketches that enabled me to understand my mistake.

You may find below the boiler tank and condenser overall sketch as well as a detailed one of the condenser + nozzle position.View attachment 623399 View attachment 623400

I initially went for a 90° full cone nozzle and installed it 2 inches upper the tee inlet, therefore option 1 in the above sketch. As you may see it, it is simply mathematical that it would spray in the inlet tube. ugh!

Ideal option is option 3, but I am afraid it won’t be efficient in my 4” setting. A lot of steam will get through between inlet and nozzle.

In order to get it right, I need to go for option 3 but with a 60° cone nozzle. This way I will be able to position the nozzle just at the inlet of the tee and still yield option 3 optimal spraying result.

Don't sweat your efficiency concern. Go with option 3 - the condensation creates a local vacuum that pulls steam in.

Regarding the spray angle - what you do not want is spray water hitting the walls of the tube - that water is not condensing steam nearly as much and is effectively wasted. Perhaps a 60 degree pattern is better then.

Derry

Member

Don't sweat your efficiency concern. Go with option 3 - the condensation creates a local vacuum that pulls steam in.

Regarding the spray angle - what you do not want is spray water hitting the walls of the tube - that water is not condensing steam nearly as much and is effectively wasted. Perhaps a 60 degree pattern is better then.

Thanks. Will do and keep you posted.

will post some pictures of it.

Nice info. You could take an arbitrary measurement of the kettle and exhaust tube from this picture and come up with a ratio for the required diameter of any exhaust tube.If you look at the condensers used in large breweries you'll see the nozzles are mounted quite low in the discharge tube.

View attachment 623410 View attachment 623411

Diameter of either really doesn't matter. What matters is the amount of energy in the steam being pulled out enough for it to condense into liquid.

Gravitysucks

Well-Known Member

Nice info. You could take an arbitrary measurement of the kettle and exhaust tube from this picture and come up with a ratio for the required diameter of any exhaust tube.

I'm not sure you could really determine anything from those pictures. I just posted them because @Derry seemed concerned that because he was using larger piping that his spray nozzle needed to be very high in the pipe to work.

Can you explain what you mean by an "Air gap?"

An air gap is when a discharge pipe or hose ends some distance above the drain pipe. The drain is larger to catch everything. Sometimes a floor sink is used. Sometimes a funnel. Sometimes it’s a piece of hardware that ties everything together like the ones for dishwashers.

The idea is that if the drain backs up, the waste water spreads across the floor rather than continuing up to your boil kettle.

https://en.m.wikipedia.org/wiki/Air_gap_(plumbing)

Derry

Member

I'm not sure you could really determine anything from those pictures. I just posted them because @Derry seemed concerned that because he was using larger piping that his spray nozzle needed to be very high in the pipe to work.

I wasn’t concerned. I have just made a big mistake in my calculations overlooking the fact that sprayed water will return to kettle (basically went for option 1 in my sketch whereas I should have went for 3)

I wasn’t concerned. I have just made a big mistake in my calculations overlooking the fact that sprayed water will return to kettle (basically went for option 1 in my sketch whereas I should have went for 3)

Same here. Option 3 is the way to go to avoid water and condensate returning to the kettle. The McMaster spray nozzles have a wide enough spray pattern that I wouldn't worry about the Option 3 nozzle positioning causing an issue condensing steam in 2" or larger piping as long as you have several inches of pipe (>2-4" maybe) below the nozzle.

Dag Jakobsen

New Member

- Joined

- Apr 25, 2019

- Messages

- 2

- Reaction score

- 0

Hi HBT,

The idea is that ambient temp water sprayed into a chamber where steam exists will cool the steam and cause it to phase change back to liquid. In doing so, the steam's volume contracts about 1500x, in turn creating a local area of vacuum, pulling in more steam and continuing the cycle.

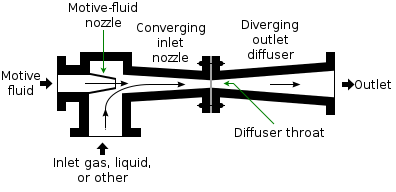

Has one considered the Venturi effect. If you increase the speed (of air, steam) the pressure decreases and thus make a vacuum. But this requires the flow not to be restricted in any way. I would think that if you omit the hose barb in the bottom and keep the bottom completely open you will create a fair amount of suction on the inlet side. What will create the more powerful vacuum, the cooling or the Venturi?

I don't think the Venturi effect applies when there is an open end on the condenser (i.e., no hose nipple), because the steam is condensing in a pipe of equal diameter to the inlet pipe for the steam and the velocity is decreasing, not increasing as you would see with a Venturi effect.

Put a hose barb on the end and water comes out, not gas, so maybe then there is some Venturi due to the constriction. But this is making my brain hurt .

.

Could the steam condenser be improved by putting a cone on the bottom below the "T" for the spray nozzle?!

There is definitely suction generated by the condensation of the steam without any fittings on the "T" below the spray nozzle.

On a related note, I have been contempating the applicability of a "steam ejector" design for condensing kettle steam, but I'm uncertain if the low-pressure steam generated by our kettles would be efficient. Steam ejectors tend to be used with very high pressure steam (motive fluid).

Put a hose barb on the end and water comes out, not gas, so maybe then there is some Venturi due to the constriction. But this is making my brain hurt

Could the steam condenser be improved by putting a cone on the bottom below the "T" for the spray nozzle?!

There is definitely suction generated by the condensation of the steam without any fittings on the "T" below the spray nozzle.

On a related note, I have been contempating the applicability of a "steam ejector" design for condensing kettle steam, but I'm uncertain if the low-pressure steam generated by our kettles would be efficient. Steam ejectors tend to be used with very high pressure steam (motive fluid).

The spray water has some forward velocity, so that does create some vacuum/pressure. This is similar to the motive fluid nozzle above.

There may be a better aka more ideal design to the condenser, but I built the initial iteration using off the shelf parts, and it worked supremely well, so I didn’t chase alternate designs.

There may be a better aka more ideal design to the condenser, but I built the initial iteration using off the shelf parts, and it worked supremely well, so I didn’t chase alternate designs.

Dag Jakobsen

New Member

- Joined

- Apr 25, 2019

- Messages

- 2

- Reaction score

- 0

The spray water has some forward velocity, so that does create some vacuum/pressure. This is similar to the motive fluid nozzle above.

Just what I was thinking!

I've made a similar design of 100mm PVC waste pipe (totally open bottom) and there was definitely a great deal of vacuum. I tested with holding a match just in front of the steam inlet and the flame went out immediately. The nozzle used was way too small to cool the steam efficiently (1gal./hour), and the PVC pipe also couldn't handle the temperature, so the project was terminated.

I am currently building one of 54mm copper tube, with a 9gal./hour nozzle. Hope this will do it!

Edit: The Venturi effect is not dependent on some constriction, just increase in velocity in some way. It is important that there is no restriction to reduce the velocity.

Some brewers even use a piece of hose with a large number of 1mm holes in it to drain wort from the boiler to the fermenter. The wort will not leak out of the holes, instead air will be sucked into the wort through the holes and provide ready airated wort in the fermenter.

Last edited:

Well, I just finished with my first brew session with the steam slayer. I have it soldered the the side of my kettle, and then draining to my catch drain for my HVAC.

It worked flawlessly. And, I'm honestly so impressed, and can't wait to brew again. I used to brew in my garage, I've since moved and made a dedicated brew area. And, I used to have to run the heater to get rid of the steam in my garage, now, nothing. Just great.

The smell, alright guys, get over it. I asked my pregnant wife to come downstairs and smell it, and she can't even wear perfume, and she said it smells like the garage after you brew. So, meh she said it stinks, the I would have said deal with it. I honestly don't understand the issue with this???

My only catch is figuring out my kettle volume, which will come with time.

It worked flawlessly. And, I'm honestly so impressed, and can't wait to brew again. I used to brew in my garage, I've since moved and made a dedicated brew area. And, I used to have to run the heater to get rid of the steam in my garage, now, nothing. Just great.

The smell, alright guys, get over it. I asked my pregnant wife to come downstairs and smell it, and she can't even wear perfume, and she said it smells like the garage after you brew. So, meh she said it stinks, the I would have said deal with it. I honestly don't understand the issue with this???

My only catch is figuring out my kettle volume, which will come with time.

Attachments

Great to hear!

Well, I just finished with my first brew session with the steam slayer. I have it soldered the the side of my kettle, and then draining to my catch drain for my HVAC.

It worked flawlessly. And, I'm honestly so impressed, and can't wait to brew again. I used to brew in my garage, I've since moved and made a dedicated brew area. And, I used to have to run the heater to get rid of the steam in my garage, now, nothing. Just great.

The smell, alright guys, get over it. I asked my pregnant wife to come downstairs and smell it, and she can't even wear perfume, and she said it smells like the garage after you brew. So, meh she said it stinks, the I would have said deal with it. I honestly don't understand the issue with this???

My only catch is figuring out my kettle volume, which will come with time.

I'll admit the aroma is different than previous brew days. It used to smell more like caramel or malt. The waste from the slayer is definitely more like DMS and hop tea. I noticed it more on a recent brew day where I run the waste into a standpipe on the drain similar to how a washing machine drains in a finished laundry room. That pipe leads into a bathroom and taps into the sink's tailpiece pre-trap. That door was closed for the whole boil so the smell was coming out of the drain and filling the bathroom. On the last batch, I plugged the drain in that sink and could barely pick up the smell.

The way I look at it, I'd rather smell DMS on brew day than black mold a year from now.

I agree, I have 5-6 brews now with the condenser and after the first brew with a the condensate running into a bucket (sharp DMS smell lingered for 3-4hrs) I ran some PVC to my sump and run my drain to the PVC and smell is much more tolerable. I expect brewing in a garage has a lot less impact to the whole house than brewing in a basement where the HVAC system is. I wouldn't even consider it a worry if brewing in a garage. It was never enough to go back to a vent but it certainly wasn't pleasant like what a would consider that of a normal brew day. That said, this is a really awesome innovation...plus it saves energy (run my 240v boil coil at 38% vs 80% w/o the condenser).

processhead

Well-Known Member

I can imagine the condensate concentrates all the smelly/volatile compounds that were in the steam. Catching the condensate in a closed vessel is a good idea, then drain it off somewhere else where it won't be released indoors. That's tough to do without some creative plumbing on a dedicated indoor drain line, or an outdoor drain.

Last edited:

I agree, I have 5-6 brews now with the condenser and after the first brew with a the condensate running into a bucket (sharp DMS smell lingered for 3-4hrs) I ran some PVC to my sump and run my drain to the PVC and smell is much more tolerable. I expect brewing in a garage has a lot less impact to the whole house than brewing in a basement where the HVAC system is. I wouldn't even consider it a worry if brewing in a garage. It was never enough to go back to a vent but it certainly wasn't pleasant like what a would consider that of a normal brew day. That said, this is a really awesome innovation...plus it saves energy (run my 240v boil coil at 38% vs 80% w/o the condenser).

The air in the basement is not drawn into the HVAC at all under normal conditions.

Yeah, I have returns on each floor of my house. The basement return is is not in the brewery but still in the basement. I’m sure most of the smell mostly just percolates up through the floor though (I have exposed joists). Either way, the smell is mostly eliminated by running the drain to the sump.

#Buckeye Brewer#

Member

- Joined

- Feb 19, 2019

- Messages

- 9

- Reaction score

- 1

This may be a captain obvious question, but how big of a hole do you cut in the kettle for the 1.5 steam slayer. Is the hole 1.5” or should it be smaller? Are greenlee chassis punches the best way to cut the hole?

I used a 42mm carbide tipped hole saw for both of my 1.5" TC bulkheads. It worked really well, just make sure you use cutting fluid, drill a pilot hole, and go slow. I wasn't interested in spending what the punch cost, way too expensive.This may be a captain obvious question, but how big of a hole do you cut in the kettle for the 1.5 steam slayer. Is the hole 1.5” or should it be smaller? Are greenlee chassis punches the best way to cut the hole?

Similarly, I used this 40mm carbide tipped hole saw. I'm pretty sure BrewHardware sells a similar hole saw and provides instructions. The punch is probably the cleanest route, but very expensive unless you're using it for a lot of holes or can share it with your club and amortize the cost.This may be a captain obvious question, but how big of a hole do you cut in the kettle for the 1.5 steam slayer. Is the hole 1.5” or should it be smaller? Are greenlee chassis punches the best way to cut the hole?I used a 42mm carbide tipped hole saw for both of my 1.5" TC bulkheads. It worked really well, just make sure you use cutting fluid, drill a pilot hole, and go slow. I wasn't interested in spending what the punch cost, way too expensive.

Similar threads

- Replies

- 2

- Views

- 908

- Replies

- 1

- Views

- 496

- Replies

- 11

- Views

- 930

![Craft A Brew - Safale BE-256 Yeast - Fermentis - Belgian Ale Dry Yeast - For Belgian & Strong Ales - Ingredients for Home Brewing - Beer Making Supplies - [3 Pack]](https://m.media-amazon.com/images/I/51bcKEwQmWL._SL500_.jpg)