Yea thats what I was thinking. I guess I could put it in the lid but it might be slightly cumbersome when adding hops etc

I originally planned on a lid port but drew the same conclusion you did, i.e., it'd be harder to maneuver.

Yea thats what I was thinking. I guess I could put it in the lid but it might be slightly cumbersome when adding hops etc

Hmmm interesting. I was originally interested in this project but the amount of space it needed was abit of a deal breaker as my kettles usually only has about 2 inches from the top on a full batch. With the elbows is it possible to fill past the port in the top of the kettle? Another question is I generally boil off about 2 gallon per hour any ideas how much waste water that would create? I do not have a drain close enough currently so would have to collect the waste water in buckets. Cheers

I think I'd need to go to a larger kettle but that brings its own set of issued. Thats my normal preboil of 20.5 gallons@Elky explained the first part. As far as how much waste water, it's whatever the GPH is for your water spray plus what you condense.

The reason I have the elbows is there are instances where I have to preboil about 8.5 gallons of water, which runs up pretty close to my TC port. The elbows will allow me a little slop in the system, if you will, whereas without them I'd lose some of that boiling water out of the port.

Won't our pre-boil volumes need to be smaller, on account of the lower boil-off volume? So perhaps those existing ports may not be too low.I think I'd need to go to a larger kettle but that brings its own set of issued. Thats my normal preboil of 20.5 gallons View attachment 587908

I've been intrigued by this idea, but I think we may have run into a snag--depending on the rate at which waste water will flow. I have a 50 gpd membrane, but on a good day it might do 1.5 gallons per hour--depends on how warm the water is. If I have a 4-1 rejection rate, in an hour I'm only producing maybe 6 gallons of reject water. I ordered the 9 gph sprayer, but I'm hoping I can turn that down a bit with the valve. If not, I may not be able to produce enough reject water.

Just a thought such that anyone planning this make sure their system has the waste necessary to do this.

I think I'd need to go to a larger kettle but that brings its own set of issued. Thats my normal preboil of 20.5 gallons View attachment 587908

Are you using a 1.5 tclamp? In your picture it looks alot bigger. If 1.5 is all that's needed plus the reduction in boiloff it might be doable. I also tinker with hydroponics and not having to have so many exhausts out the window would be Nice. CheersI'm thinking if you put that TC port as high as possible and used those 90-degree elbows, it would work.

Are you using a 1.5 tclamp? In your picture it looks alot bigger. If 1.5 is all that's needed plus the reduction in boiloff it might be doable. I also tinker with hydroponics and not having to have so many exhausts out the window would be Nice. Cheers

As I clarified above, my boil-off/evaporation volume has decreased to less than 50% the open burner rate.Won't our pre-boil volumes need to be smaller, on account of the lower boil-off volume? So perhaps those existing ports may not be too low.

I have an unused 1/2" NPT port on the top of my kettle... if i were to use a 1/2" NPT to 1.5" TC adapter, would this still work or is the hole too small?

Earlier in this thread are references to an option of this design offered by Brew Boss. I think they use a 1/2" camlock to attach to the kettle. I'm not sure anyone here will guarantee that 1/2" port will suffice, but if Brew Boss is still selling it this way, I would assume that their customers have had satisfactory results. My 1.5"TC on a 20G kettle works superbly. I imagine a 1" or even 3/4" TC might still get the job done (but of course you're proceeding at your own risk).What's the smallest sized tclamp this would work with? Cheers

I'm putting mine in the lid for this very reason, this is not mine just found this on another forumI think I'd need to go to a larger kettle but that brings its own set of issued. Thats my normal preboil of 20.5 gallons

I originally planned on a lid port but drew the same conclusion you did, i.e., it'd be harder to maneuver.

Yea thats what I was thinking. I guess I could put it in the lid but it might be slightly cumbersome when adding hops etc

Good ideaIf you wanted to get fancy you could throw a 3" tri clamp fitting on the lid, then put a 3" T on it with a block off plate on the top and attach the condenser on the side port via a step-down. This would allow you to open the blank off port for hop additions or hydrometer samples without needing to remove the lid.

Practical, not really, but it would be pretty freakin cool.

Good idea

I didnt ship any out yet on account of particular vendor screwing me over on one crucial part. All should go out Monday.

Yes, order now

I didnt ship any out yet on account of particular vendor screwing me over on one crucial part. All should go out Monday.

The last piece I need to solve is chilling. Currently I use an immersion chiller. the issue with this is that my current process is to drop it in for the last 10 minutes of the boil. But since the lid can't be on this will be a problem for the condenser.

I think I have a solution for this, but I'm curious what others suggest. What i'm planning on doing is adding two more 1/2" NPT fittings to my lid and modifying my immersion chiller to have two cam locks, or ball locks, or some other quick disconnect on the ends. Before the boil I can attach the chiller to the lid and just leave it in for the full boil. The only thing I'm trying to research is if it's ok to boil a copper chiller the whole length of the boil or should I just invest in a stainless one for this?

I could make the switch to a counterflow or plate chiller, but I like being able to see the surfaces that touch the beer to make sure they're clean. Feel free to convince me one of these is the better option.

I like a CFC, especially a SS one, but that's a personal call. I would not boil a copper coil.

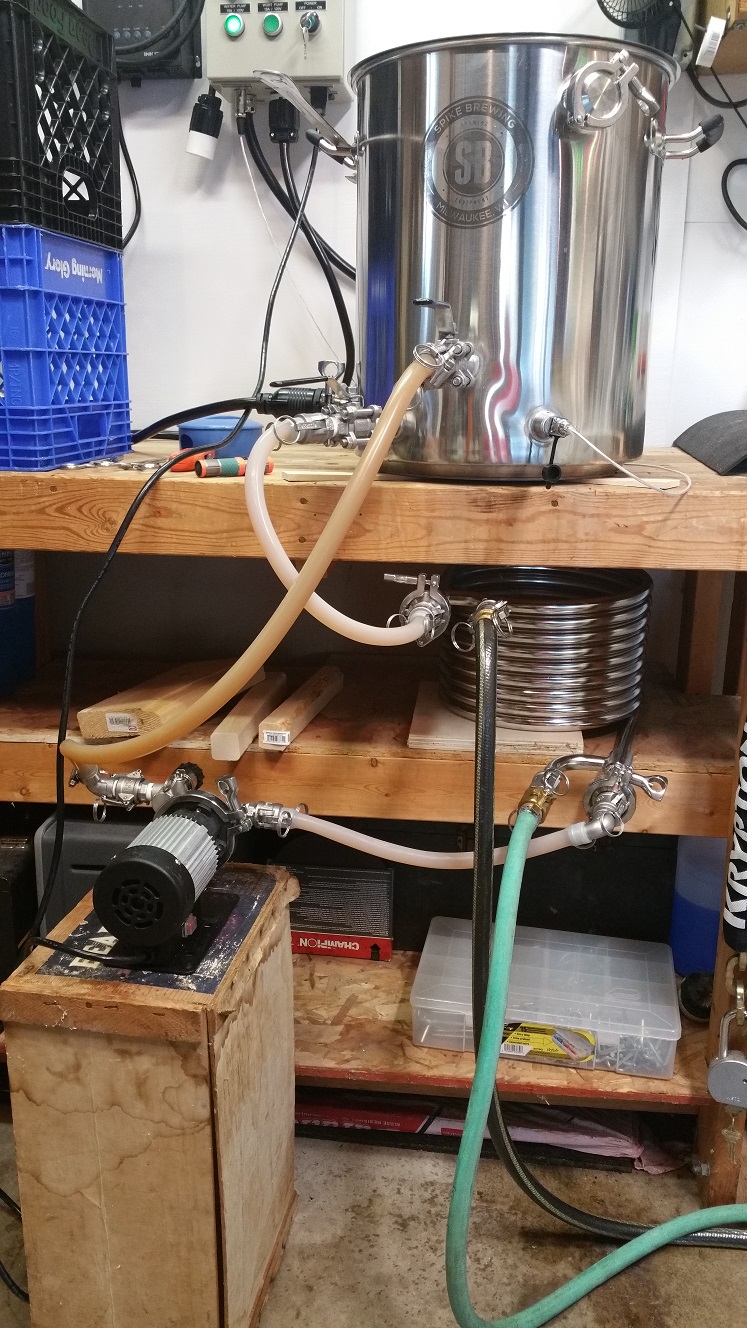

That looks like the Stout Tanks Counterflow. I've got the same one.Hi @mongoose33... what chiller is that?

Hi @mongoose33... what chiller is that?

That looks like the Stout Tanks Counterflow. I've got the same one.