You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Boil kettle condenser - no overhead ventilation needed

- Thread starter BrunDog

- Start date

Help Support Homebrew Talk:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

Glad to hear! Loving mine too!

aeviaanah

Well-Known Member

- Joined

- Jul 1, 2012

- Messages

- 1,686

- Reaction score

- 217

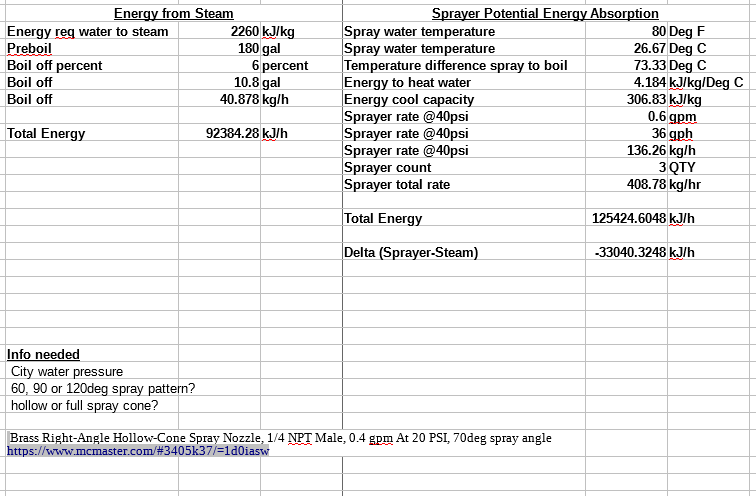

I worked up a spread sheet using a picture you posted as a reference.The spray can go in any direction. They key is maximum mixing... if you come in from the side, get wide angle nozzles. Spraying water onto the sidewall serves no purpose.

I plan to use 4" triclover assembly like shown below, using 90deg sprayer nozzles 70deg pattern in vertical tube.

https://www.mcmaster.com/#31975K12

The design will be similar in nature to Stouts version (thanks Auggie), trying to figure out why they went with 6" instead of smaller..

https://conical-fermenter.com/SP500CONDENSER-1325-Condenser.html

I'm estimating 6% for boil off but have no clue, It will be electric so I'm sure we can hit whatever boil off we want. You think 6% is a good starting point? I appreciate the help.

Last edited:

Your math is generally correct but seems impractical at this scale and spray water temp. I calculate needing a theoretical net spray volume ~80 gph. That's a lot of water to dump. You could target a lower boil-off, say 4%, but it might be hard to control to maintain a boil so I would stay with the current rate.

With this size boil, you might consider the standard vent stack as a more practical solution.

With this size boil, you might consider the standard vent stack as a more practical solution.

aeviaanah

Well-Known Member

- Joined

- Jul 1, 2012

- Messages

- 1,686

- Reaction score

- 217

Your math is generally correct but seems impractical at this scale and spray water temp. I calculate needing a theoretical net spray volume ~80 gph. That's a lot of water to dump. You could target a lower boil-off, say 4%, but it might be hard to control to maintain a boil so I would stay with the current rate.

With this size boil, you might consider the standard vent stack as a more practical solution.

Can you elaborate on how you figure 80 gph? Spray water temp was conservative based on ground water average, it can be much lower if we pull from CLT.

That's the math. Your own math above is 36 * 3 = 108 gph. That is why you have a surplus of cooling power. My 5 gallon batch boil off is 1 gph, yours is 10, hence why you need 10x the cooling power of my ~7.5 gph spray rate.

$479.00

$559.00

EdgeStar KC1000SS Craft Brew Kegerator for 1/6 Barrel and Cornelius Kegs

Amazon.com

$58.16

HUIZHUGS Brewing Equipment Keg Ball Lock Faucet 30cm Reinforced Silicone Hose Secondary Fermentation Homebrew Kegging Brewing Equipment

xiangshuizhenzhanglingfengshop

$53.24

1pc Hose Barb/MFL 1.5" Tri Clamp to Ball Lock Post Liquid Gas Homebrew Kegging Fermentation Parts Brewer Hardware SUS304(Liquid Hose Barb)

Guangshui Weilu You Trading Co., Ltd

$10.99 ($31.16 / Ounce)

Hornindal Kveik Yeast for Homebrewing - Mead, Cider, Wine, Beer - 10g Packet - Saccharomyces Cerevisiae - Sold by Shadowhive.com

Shadowhive

$20.94

$29.99

The Brew Your Own Big Book of Clone Recipes: Featuring 300 Homebrew Recipes from Your Favorite Breweries

Amazon.com

$7.79 ($7.79 / Count)

Craft A Brew - LalBrew Voss™ - Kveik Ale Yeast - For Craft Lagers - Ingredients for Home Brewing - Beer Making Supplies - (1 Pack)

Craft a Brew

$22.00 ($623.23 / Ounce)

AMZLMPKNTW Ball Lock Sample Faucet 30cm Reinforced Silicone Hose Secondary Fermentation Homebrew Kegging joyful

无为中南商贸有限公司

$53.24

1pc Hose Barb/MFL 1.5" Tri Clamp to Ball Lock Post Liquid Gas Homebrew Kegging Fermentation Parts Brewer Hardware SUS304(Liquid MFL)

yunchengshiyanhuqucuichendianzishangwuyouxiangongsi

$176.97

1pc Commercial Keg Manifold 2" Tri Clamp,Ball Lock Tapping Head,Pressure Gauge/Adjustable PRV for Kegging,Fermentation Control

hanhanbaihuoxiaoshoudian

$33.99 ($17.00 / Count)

$41.99 ($21.00 / Count)

2 Pack 1 Gallon Large Fermentation Jars with 3 Airlocks and 2 SCREW Lids(100% Airtight Heavy Duty Lid w Silicone) - Wide Mouth Glass Jars w Scale Mark - Pickle Jars for Sauerkraut, Sourdough Starter

Qianfenie Direct

aeviaanah

Well-Known Member

- Joined

- Jul 1, 2012

- Messages

- 1,686

- Reaction score

- 217

That's the math. Your own math above is 36 * 3 = 108 gph. That is why you have a surplus of cooling power. My 5 gallon batch boil off is 1 gph, yours is 10, hence why you need 10x the cooling power of my ~7.5 gph spray rate.

Ah my bad, I was looking at the cell as a total. Even after plugging this in at 40degrees sprayer temp, we would be using 72 gallons total. I’ll reevaluate this with my partner..

You could get creative and pump the spray/discharge water through a radiator/fan as an liquid:air heat exchanger. It will create local heat but if you put that remote to your working space, it would work. You could use a grant (or bucket, etc.) which can overflow into a drain as you boil off the 10 gallons. That would only require a few gallons of water to start with.

Alternatively, you could pass the through a steam through a high flow liquid:air radiator directly I suppose!

Alternatively, you could pass the through a steam through a high flow liquid:air radiator directly I suppose!

- Joined

- Dec 16, 2015

- Messages

- 935

- Reaction score

- 355

I finally bought an 11 gallon kettle to replace my 8.5, so I'm going to finally jump on this bandwagon and build a setup that I can use 100% indoors. It'll likely take me a couple months to get all the parts ordered and assembled, but I'm excited. Will be going with a 1.5" lid mounted version with a 6gph nozzle.

Between the larger kettle size and lower boil off I'm excited to finally do some true full volume BIAB instead of the weird pseudo sparge i've been doing.

Between the larger kettle size and lower boil off I'm excited to finally do some true full volume BIAB instead of the weird pseudo sparge i've been doing.

HarpuaScorpio

Well-Known Member

Hey BrunDog, did you write the how-to in the new BYO mag?

Hey BrunDog, did you write the how-to in the new BYO mag?

I was wondering the same thing.

I did!

HarpuaScorpio

Well-Known Member

That's awesome! Congrats! It's quite a remarkable project and deserves the spotlight. I was really hoping they didn't just have someone write up a summary of this huge thread.I did!

jahlinux

Well-Known Member

- Joined

- Dec 16, 2015

- Messages

- 157

- Reaction score

- 44

You deserve a lot of credit! It’s an awesome addition to my basement brewery.I did!

Thanks. They were great... reached out and asked if I would be interested in writing up the project. Good people over there!

ancientmariner52

Well-Known Member

Thank you so much! I've followed this thread for some time, but your article ties everything up with a pretty bow. Well done!I did!

enormous13

Well-Known Member

Looks like Bobby might be offering up a kit soon for this, his Instagram had a "prototype" in action. Would be great to buy it all in one stop.

aeviaanah

Well-Known Member

- Joined

- Jul 1, 2012

- Messages

- 1,686

- Reaction score

- 217

You could get creative and pump the spray/discharge water through a radiator/fan as an liquid:air heat exchanger. It will create local heat but if you put that remote to your working space, it would work. You could use a grant (or bucket, etc.) which can overflow into a drain as you boil off the 10 gallons. That would only require a few gallons of water to start with.

Alternatively, you could pass the through a steam through a high flow liquid:air radiator directly I suppose!

At this point an exhaust fan is looking more and more attractive!! Thanks for all of your help, I appreciate it.

Great write-up, both here and in BYO, Pete. Kudos!I did!

Thank you [emoji120].

Looks like Bobby might be offering up a kit soon for this, his Instagram had a "prototype" in action. Would be great to buy it all in one stop.

Good eye! The picture is pretty close to the finished design but I'll post some pics of the final one very soon. The tee is more like an instrument tee, but the side port is closer to the top to leave more space for the condensing. The bottom skips the TC flange, clamp and gasket and just has a 5/8" hose barb welded. Instead of a compression fitting as shown on the top, there will be a 90 degree shutoff valve with a push to connect fitting for the water supply. I'm planning to include some length of PE tubing and a female garden hose fitting on the far end. The sprayer tip is threaded in to a tube that is welded to the TC cap/adapter. The whole plan was to make it as compact and inexpensive as possible. I had great success running the 6gpm @ 40psi and reducing my normal power input of 60% down to 30%.

gph....

Right. 360 gallons later....gph....

Mybuddypete

Well-Known Member

- Joined

- Jul 10, 2013

- Messages

- 46

- Reaction score

- 16

I'll pretty much buy one as soon as it is available Bobby. I bought the 18" RIMS tube with the welded cam lock fitting you sell last week and just used it yesterday for the first time and I am very impressed with the quality.Good eye! The picture is pretty close to the finished design but I'll post some pics of the final one very soon. The tee is more like an instrument tee, but the side port is closer to the top to leave m...

kal

Well-Known Member

Great article BrunDog! BYO had asked me back in May to 'review for technical accuracy' and frankly I couldn't find very much to comment on (other than an extremely minor typo or two).Congrats!

Kal

Thanks Kal. I tried to pay more homage to you - your humbleness perhaps explains the edit!

kal

Well-Known Member

Ha! Yes, you noticed that.  Cheers!

Cheers!

Kal

Kal

Die_Beerery

Well-Known Member

- Joined

- Aug 21, 2017

- Messages

- 842

- Reaction score

- 643

Thanks. They were great... reached out and asked if I would be interested in writing up the project. Good people over there!

And they pay. [emoji41]

TANSTAAFB

Well-Known Member

Awesome, please let us know when it's available!Good eye! The picture is pretty close to the finished design but I'll post some pics of the final one very soon. The tee is more like an instrument tee, but the side port is closer to the top to leave more space for the condensing. The bottom skips the TC flange, clamp and gasket and just has a 5/8" hose barb welded. Instead of a compression fitting as shown on the top, there will be a 90 degree shutoff valve with a push to connect fitting for the water supply. I'm planning to include some length of PE tubing and a female garden hose fitting on the far end. The sprayer tip is threaded in to a tube that is welded to the TC cap/adapter. The whole plan was to make it as compact and inexpensive as possible. I had great success running the 6gpm @ 40psi and reducing my normal power input of 60% down to 30%.

View attachment 577652

@BrunDog I was wondering if that was you! Great job on the write up, I've been following this thread for a minute and still had some head scratchin that the article cleared right up. And Bobby taking it and simplifying things makes it even easier (and cheaper [emoji6]) than sourcing and building. Plus, despite some entitled a$$hats out there [emoji85] [emoji86] [emoji87] I know his customer service is top notch!

And they pay. [emoji41]

Any compensation will be donated.

Similar threads

- Replies

- 2

- Views

- 906

- Replies

- 1

- Views

- 482

- Replies

- 11

- Views

- 910

![Craft A Brew - Safale BE-256 Yeast - Fermentis - Belgian Ale Dry Yeast - For Belgian & Strong Ales - Ingredients for Home Brewing - Beer Making Supplies - [3 Pack]](https://m.media-amazon.com/images/I/51bcKEwQmWL._SL500_.jpg)