rudylyon57

Well-Known Member

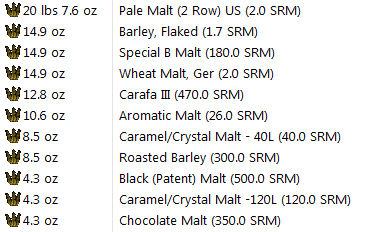

Have an Imperial Stout that is stuck at 1.050. 5.5 gallons into fermenter, started at 1.120, mashed at 148F, 8 lb Maris Otter, 6 lbs DME, 2 lb Crystal 80 and 4 lbs of dark grains, oats, etc. Fermenting on yeast cake from previous batch which used Muntons Premium Gold. Well oxygenated at start holding 70F.

For reference, the yeast cake came from a similar batch but used grain in place of the DME. It started at 1.112 and finished at 1.030.

Fermentation took two days to get going and moved along at a steady clip for about 4 days where it is now stuck at 1.050. I re-oxygenated and pitched hydrated S04 yesterday but after 24 hours it's looking bleak with no activity. I would like to get to 1030 to 1035.

Any suggestions?

For reference, the yeast cake came from a similar batch but used grain in place of the DME. It started at 1.112 and finished at 1.030.

Fermentation took two days to get going and moved along at a steady clip for about 4 days where it is now stuck at 1.050. I re-oxygenated and pitched hydrated S04 yesterday but after 24 hours it's looking bleak with no activity. I would like to get to 1030 to 1035.

Any suggestions?

![Craft A Brew - Safale BE-256 Yeast - Fermentis - Belgian Ale Dry Yeast - For Belgian & Strong Ales - Ingredients for Home Brewing - Beer Making Supplies - [3 Pack]](https://m.media-amazon.com/images/I/51bcKEwQmWL._SL500_.jpg)