If anyone is interested, I recently got a silver medal in the sour category with this process. I haven't yet received my score or any judging notes but here are a few tasting notes of my own.

Very pale, cloudy, effervescent. Not a whole lot on the nose, a little grainy. Taste is sharply sour, like a punch in the jaw, lots of breadiness as well.

It's probably around 4.2%

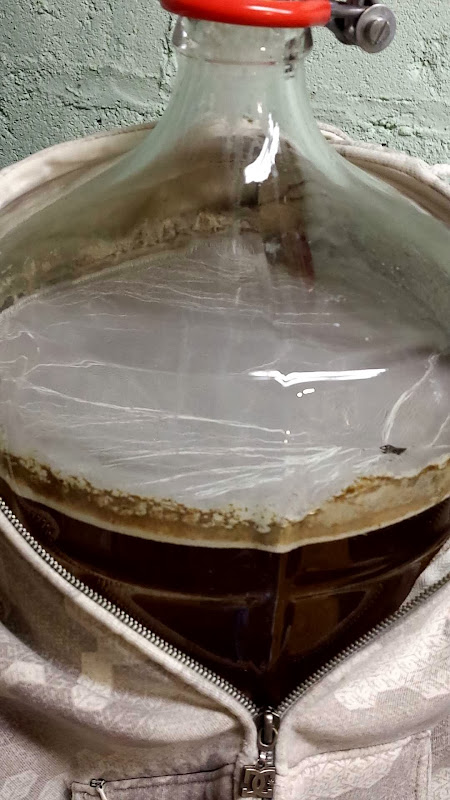

50/50 pils/wheat. Low mash temperature. For the souring, I put all of the wort in about 5 one gallon milk jugs. I added a handful of uncrushed 2-row pale malt to each jug, squeezed all of the air out and screwed caps on them. Tossed these all inside my fermentation chamber (heated with a hair dryer). I had them souring at 95F for 3 days and I still wasn't happy with how sour it was becoming so I added a bit more uncrushed grain to each and ramped up the temperature to 110 for another 3 days. Finally I was satisfied with the sourness (I like em sour), I did a quick 15 min boil with 5 IBU worth of Hallertauer. Fermented with Safale-05 at ~68F for 10 days then bottled.

I never noticed any bad aromas during fermentation. Maybe because I was able to limit the oxygen exposure to the wort.

The only problem was that one of the milk jugs cracked! That was a fun mess to clean up.......................

is all. I hope the beer turns out well. I'm interested to here feedback. I'm surprised it's not more sour having dropped from 1.038 to 1.014 with no sacch or brett added yet. It's not necessarily odd, but it certainly leaves me scratching my head.

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)