r8rphan

Well-Known Member

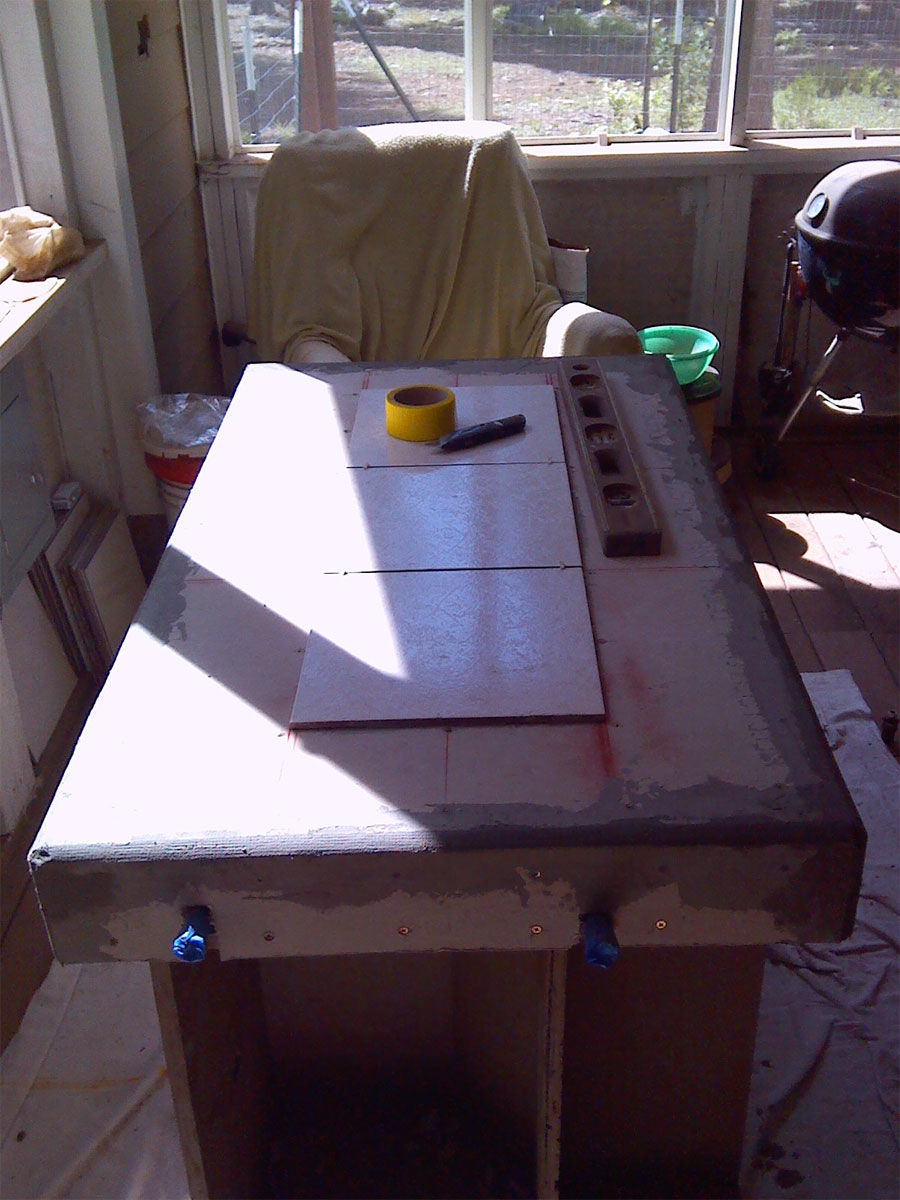

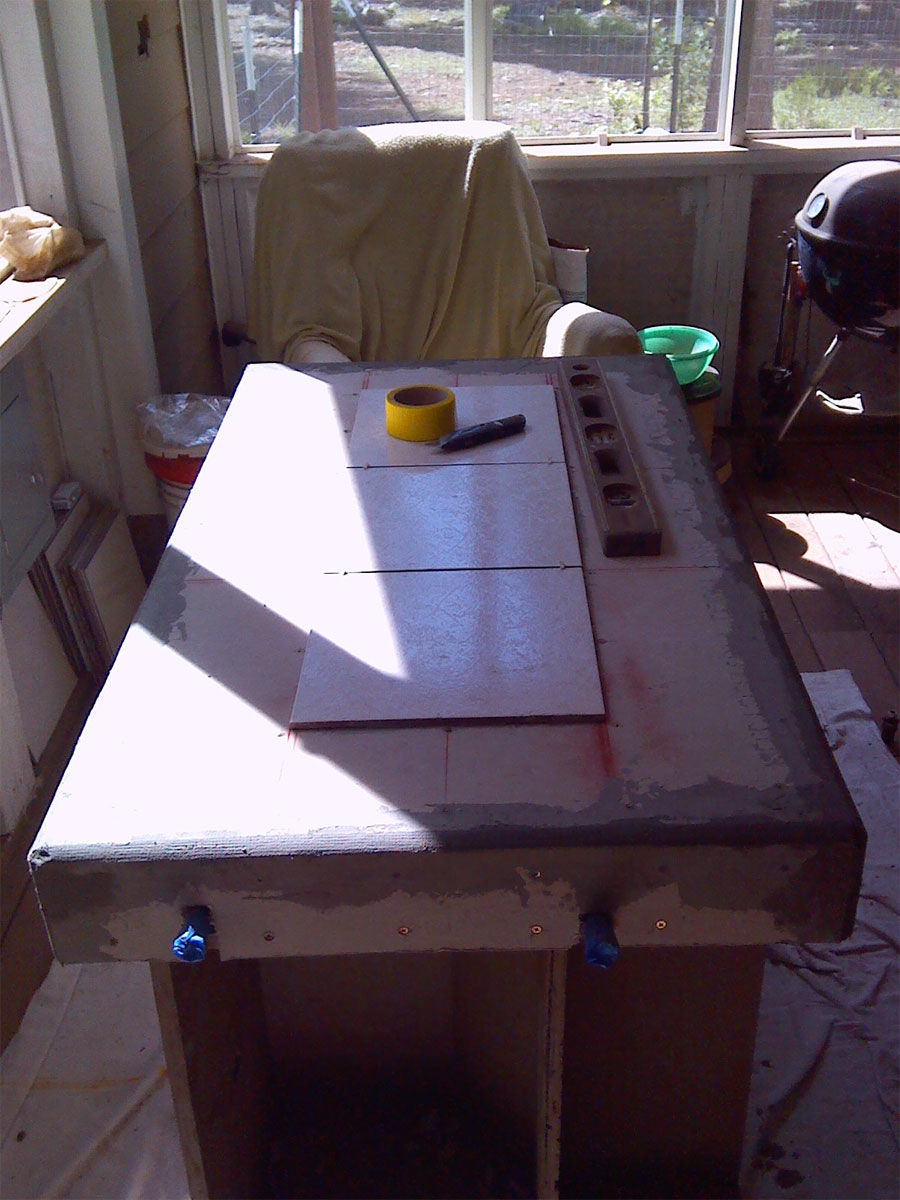

So, Thursday after work, I started tiling the brew stand... Thursday I put in the hardibacker, mortared/reinforced the edges, and set the reference tiles...

Friday I finished tiling the thing.. Quarter round tile is a PITA to install...

Saturday morning, when I removed the tape, a couple of pieces of the quarter round came loose, so I re-mortared them...

This morning (Sunday), I went into town to exchange the unsanded grout for sanded version, as I had originally planned on having no grout lines, but that plan would have left me running out of quarter round trim...

So, then I came back and grouted it in, all before noon.. When the grout dries, it should be the same color as the quarter round...

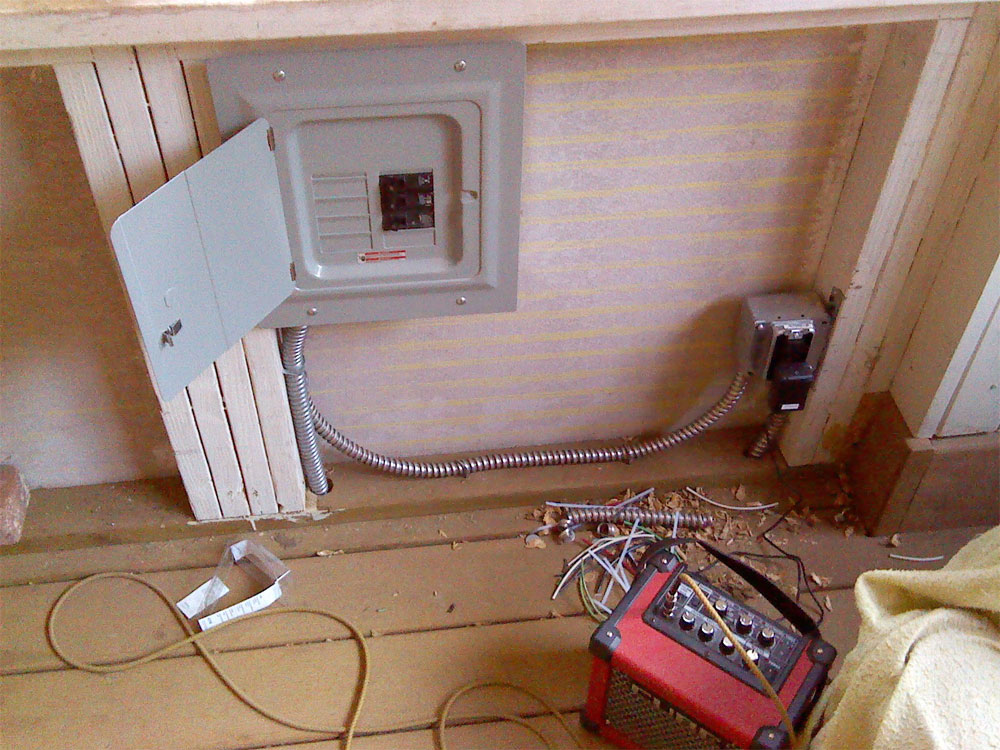

So, the brew stand is done.... Will seal it in about a month... Next up, I need to run some convenience outlets along the back wall behind the brew stand and the table next to it, and also run a 240v 30a dryer outlet to power the brewery...

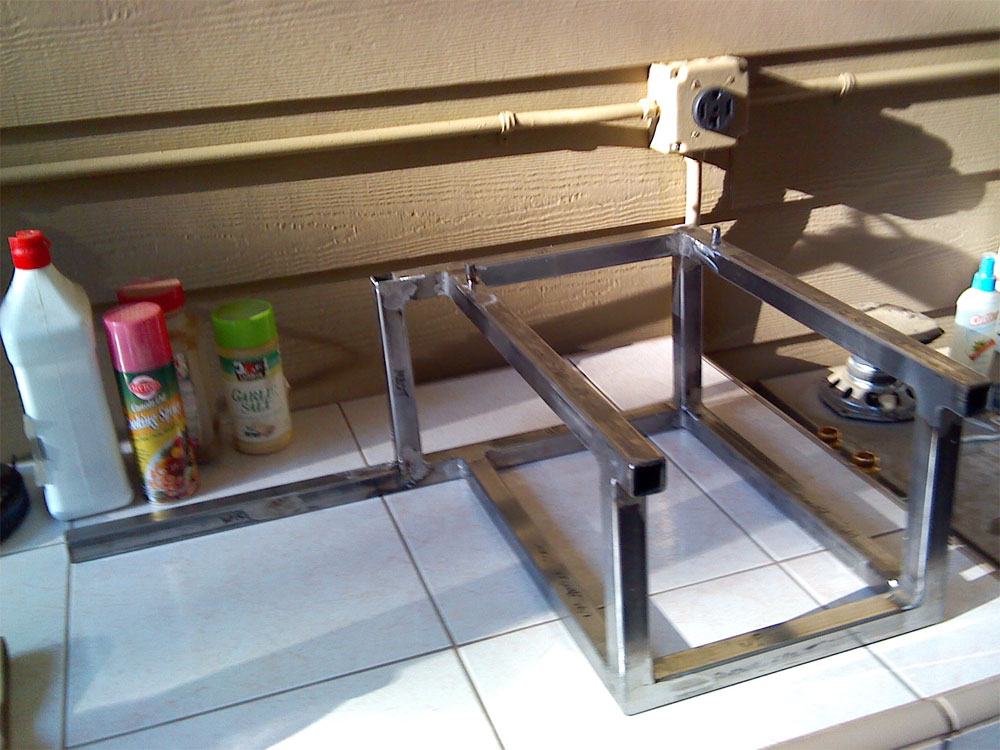

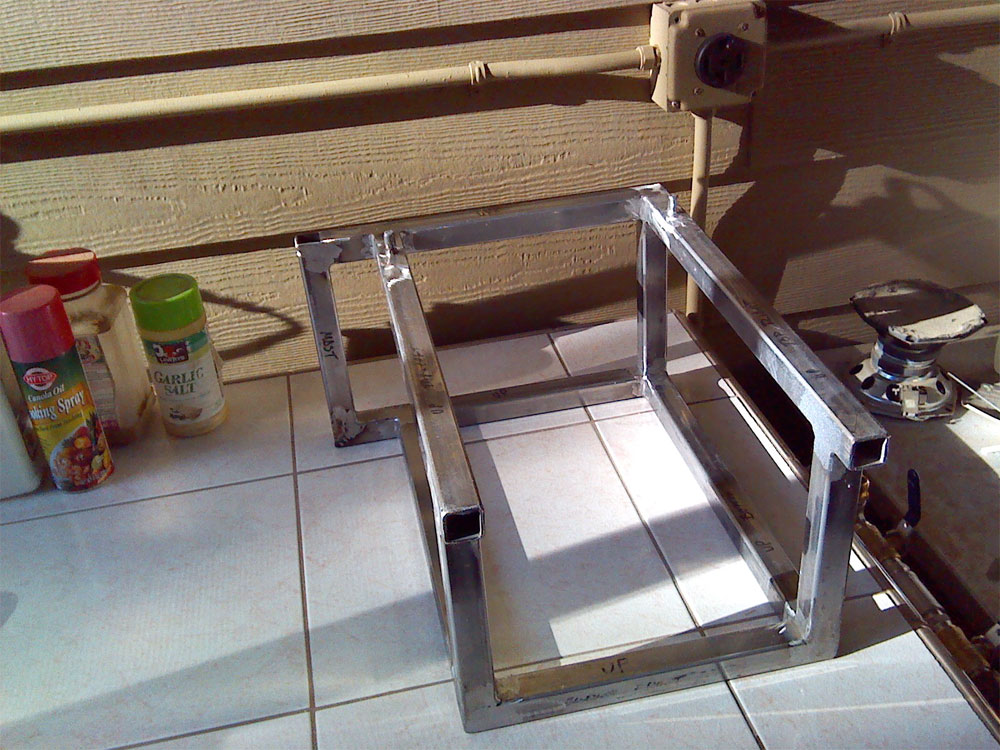

Later this week I plan to start on the steel kettle stand/grain crane....

I'm waiting for the enclosure for the electronics to arrive, and other than that I have all the parts to finish this side of the brewery... Will probably brew a couple of batches before I deal with upgrading the fermenter and kegging side later this ummer....

Progress... Glad that part is over... Later on, I'm planning to build a matching table to sit next to it, and a matching end table to use next to a chair...

Time to relax for the rest of the holiday weekend... Smoking a fat Tri-Tip tomorrow...

Friday I finished tiling the thing.. Quarter round tile is a PITA to install...

Saturday morning, when I removed the tape, a couple of pieces of the quarter round came loose, so I re-mortared them...

This morning (Sunday), I went into town to exchange the unsanded grout for sanded version, as I had originally planned on having no grout lines, but that plan would have left me running out of quarter round trim...

So, then I came back and grouted it in, all before noon.. When the grout dries, it should be the same color as the quarter round...

So, the brew stand is done.... Will seal it in about a month... Next up, I need to run some convenience outlets along the back wall behind the brew stand and the table next to it, and also run a 240v 30a dryer outlet to power the brewery...

Later this week I plan to start on the steel kettle stand/grain crane....

I'm waiting for the enclosure for the electronics to arrive, and other than that I have all the parts to finish this side of the brewery... Will probably brew a couple of batches before I deal with upgrading the fermenter and kegging side later this ummer....

Progress... Glad that part is over... Later on, I'm planning to build a matching table to sit next to it, and a matching end table to use next to a chair...

Time to relax for the rest of the holiday weekend... Smoking a fat Tri-Tip tomorrow...

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)