poptarts

Well-Known Member

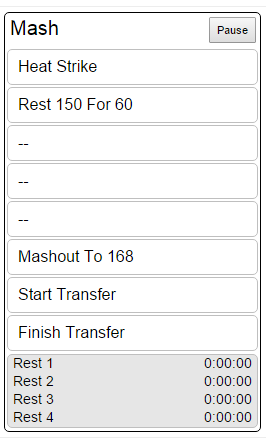

I love it when a plan comes together! Great job. How is first batch coming along??

TD

First batch stopped around 1020 so I added a lb of sugar to help dry it out. Just racked to dry hop keg over the weekend but didn't take a reading, I hope its like 1016 or so but we will have to wait and see. Tomorrow I will probably transfer to a keg and carb and get some pics and numbers for everyone, if its drinkable I will be happy.

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)