- Joined

- Jun 6, 2019

- Messages

- 33

- Reaction score

- 18

Hi All,

I would apperciate some advice on what your average times to complete fermentation for all grain brewing an IPA. I know there are several variables involved.

I am currently fermenting a SMASH IPA and here is some key items:

Any advice would be appreciated.

Cheers!

I would apperciate some advice on what your average times to complete fermentation for all grain brewing an IPA. I know there are several variables involved.

I am currently fermenting a SMASH IPA and here is some key items:

- Grain bill was 14 lb. of Ireks Pale Ale Malt

- 2 oz of LupuLN2 Cryo Hop Pellets (AA 23) - Boil: .25 oz hops at 60 min. and .25 oz hops at 10 minutes. Post boil: 1.5 oz hops @ 140 degrees

- Final volume of wort into fermenter was 6 gallons

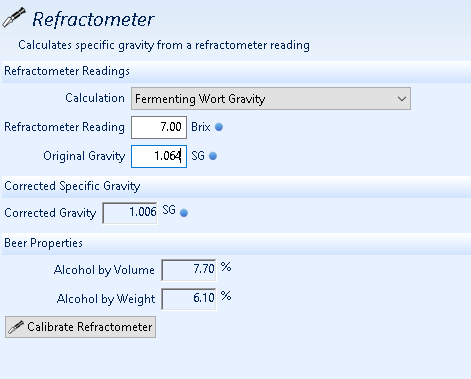

- OG 1.064 and that is what the recipe called for. Target final SG is 1.011

- day 6 of fermenting and SG is 1.027. Still showing signs of fermenting, not as robust at this point

- Safale US-05 Dry Yeast - I did a starter using the product Proper Starter and 2 packets of yeast (amount of yeast based on Brewers friend app)

- Visible signs of Fermentation within 4 hours of adding yeast to fermenter. Robust fermentation when I checked in the next morning

- I have a chiller and the ambient air is stable at 70 degrees both day and night (use AC/Heater to accomplish it). The temperatures within the fermenter have been:

- Day 1-3 - 64 degrees

- Day 4 - 65 degrees

- Day 5-6 - 66 degrees

- The change in temperature is because I am changing it. I read somewhere that doing this can help restart any dormant yeast cells

- pH of both mash and post boil were at 5.4 - this was also what the recipe called for

- I oxygenate the wort immediately after adding it to the fermenter using bottled oxygen

- Water treatment - The water I use is Ozarka Spring water (thinking of trying RO water with adjustments in the future) and I have tested it. It was too low in pH and soft water so I added 2 tsp. Gypsum to bring up pH. I'm just beginning to learn about water adjustments so I may have missed something.

Any advice would be appreciated.

Cheers!

![Craft A Brew - Safale BE-256 Yeast - Fermentis - Belgian Ale Dry Yeast - For Belgian & Strong Ales - Ingredients for Home Brewing - Beer Making Supplies - [3 Pack]](https://m.media-amazon.com/images/I/51bcKEwQmWL._SL500_.jpg)