orangehero

Well-Known Member

Brilliant idea with the spring as a filter. Everything looks super clean, although I prefer welded fittings.

I imagine with it being stainless that it should hold its shape pretty well

I will add use 5 temp sensors in my setup, all flow sensors in a BSP tee.

- HLT in, HLT out

- Mash in (from coil), Mash out

- Boil out

I will also put 4 temp sensors on the CFC cooler, just because I am curious.

Because the sensors are OneWire, it is easy to add as many as you like. Making it easy to actually use them in software is the tricky part, but we will figure it out

I will add use 5 temp sensors in my setup, all flow sensors in a BSP tee.

- HLT in, HLT out

- Mash in (from coil), Mash out

- Boil out

I will also put 4 temp sensors on the CFC cooler, just because I am curious.

Because the sensors are OneWire, it is easy to add as many as you like. Making it easy to actually use them in software is the tricky part, but we will figure it out

I think here in the USA we would use 1/2" NPT "T" stainless fittings and a 1/2" NPT to 1/4" compression fitting for the temperature probe. You take out the metal cone and use 2 - 1/4" O rings to seal the interface to the probe. This works on my current system and should work on Elkoe's new system, assuming he is using similar probes as his BrewPi system.

I would maybe put valve 14 on the other side of the CFC, that way you don't fill up the CFC with dirty water during cleaning that you just want to drain. But then again I guess it's not a big problem because the water will "choose" the easy way out the drain anyway and not go into the CFC, right? Depends on how easy the flow is out the drain side and how hard the pump is pushing on.

Like the idea with the springs filtration, where did you buy them?

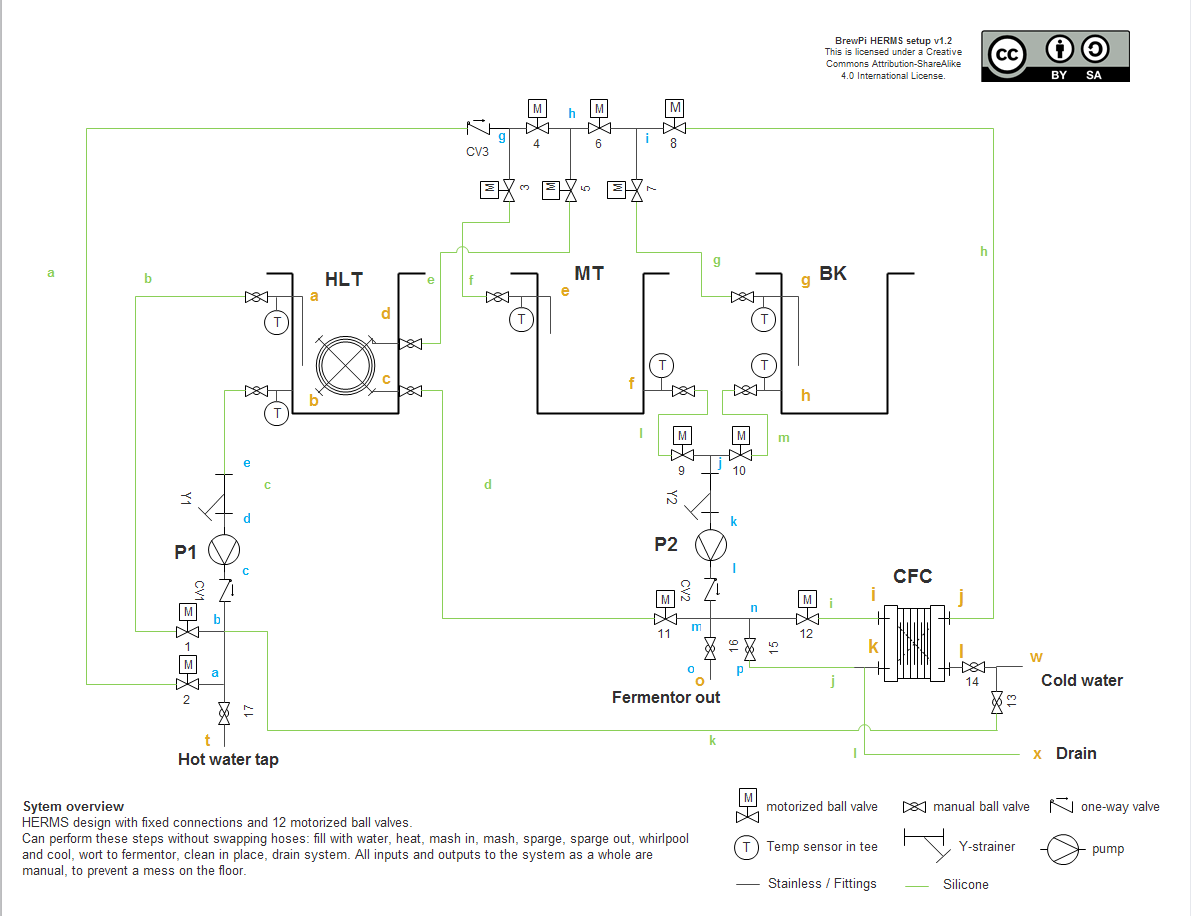

The diagram looks good. On first glance, it does look like you have more valves than you need, but if you have them it doesn't hurt. An example is valve 5 and 11... both could stop flow on that leg. 3-8 may be able to be reduced too. Here's how mine is setup. I have a few more manual operations though. Valves 1-6 and the adjacent manual valves are all part of one manifold.

http://1drv.ms/1yWET15

I saw you were using 5 wire valve control. Will you be creating boards for controlling 3 wire boards or just proving generic positive or gnd control DC? Almost all of my valves require taking the control wire to ground to open it.

I'm excited about your project and it looks great and well thought out so far. The BrewPi fermentation control is awesome.

Elkoe,

Any updates on release date?

I was thinking yesterday the same thing - Do I need to change that letter to Santa?