I'm on my 3rd brew with the 10.5 gal Anvil and the first 2 brews went well but my Mash Efficiency was low according to BS 3 and I just chalked it to learning curve.

Well I got serious with the 3rd brew and my mash efficiency is still low at 66%. Using my cooler it's in the upper 70's.

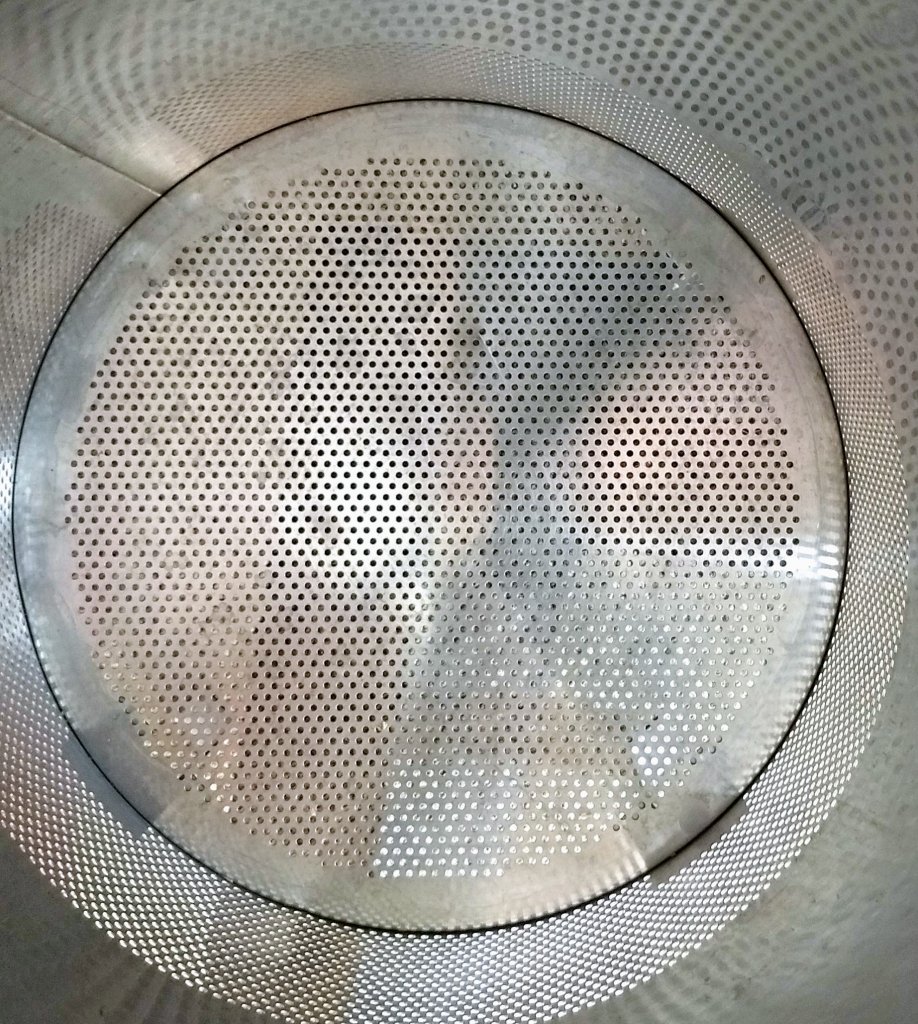

I'm thinking it's the way the mash pipe is designed with the holes 4-5 inches up the side allowing the mash water to flow out the sides and not down and out thru the whole mash. I wonder if a portion of the mash is not being sparged.

I'm thinking of doing a another brew but somehow blocking off the side holes.

Well I got serious with the 3rd brew and my mash efficiency is still low at 66%. Using my cooler it's in the upper 70's.

I'm thinking it's the way the mash pipe is designed with the holes 4-5 inches up the side allowing the mash water to flow out the sides and not down and out thru the whole mash. I wonder if a portion of the mash is not being sparged.

I'm thinking of doing a another brew but somehow blocking off the side holes.

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)