Noob_Brewer

Well-Known Member

OK, brewed today. NEIPA, ~30% white wheat/oats. This was the second brew I did on this setup with all the modifications I mentioned in post 1462. My RIS in post 1184 didn't utilize the loc-line or ball valve but did use the second kettle for a big beer. But from that RIS experience of draining the wort to the second kettle and having a big sparge with the bag in place was extremely effective (80% mash/lauter efficiency) and easy so I decided to move forward with my current setup with all modifications in post 1462. Last week I used this setup for the first time (belgian dubbel) and nailed 83.7% mash/lauter efficiency but since I was over on my pre-boil volume a little, the corrected mash/lauter efficiency was 82%. So this week I did an NEIPA which would be a true test of this setup since lots of wheat and oats. Mash/lauter efficiency was 78% on the nose. SO happy with this. Below are the pics of my current setup with modifications listed in post 1462.

Mash w/ recirculation pics (nice clear wort, only stirred the top of the bed once at 20 and 60 minutes (90min mash)):

Draining to second kettle and sparging one quart at a time to keep water level at the top of the grain bed. Nice clear wort into second kettle (pic looks red but its not lol).

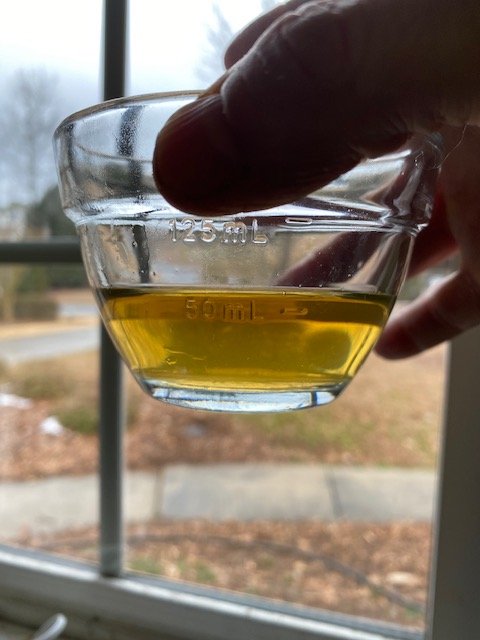

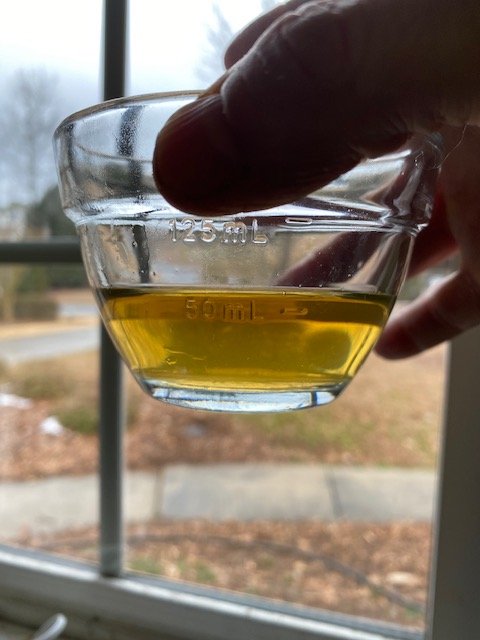

Draining back to kettle for boil after I sparged and lifted the bag to drain:

Recirc arm setup at end of hop stand (hops roam free, I don't actually whirlpool) getting ready to put the immersion chiller in and recirculate. FYI, the WP arm points to the right in the picture and the dip tube of the anvil points to the right as well when the nozzle on the outside looks like its down.

So once I chill to pitching temps (took 8 minutes today - rocking the winter temps!) I wheel the hand truck the anvil sits on over to my fermonster housed in its minifridge, start cleaning everything else while the hops and trub settle to get clear wort into the fermenter with minimal trub in the fermenter (about a little less than 0.25 gallon based on my mark). Not bad for free roaming hops Poor lighting on this pic. yeast about to be pitched.

Poor lighting on this pic. yeast about to be pitched.

So thats my current process based on my modifications. Really enjoyable brew day. Hope this helps anyone wanting to do some modifications to the system/setup.

Cheers!

Mash w/ recirculation pics (nice clear wort, only stirred the top of the bed once at 20 and 60 minutes (90min mash)):

Draining to second kettle and sparging one quart at a time to keep water level at the top of the grain bed. Nice clear wort into second kettle (pic looks red but its not lol).

Draining back to kettle for boil after I sparged and lifted the bag to drain:

Recirc arm setup at end of hop stand (hops roam free, I don't actually whirlpool) getting ready to put the immersion chiller in and recirculate. FYI, the WP arm points to the right in the picture and the dip tube of the anvil points to the right as well when the nozzle on the outside looks like its down.

So once I chill to pitching temps (took 8 minutes today - rocking the winter temps!) I wheel the hand truck the anvil sits on over to my fermonster housed in its minifridge, start cleaning everything else while the hops and trub settle to get clear wort into the fermenter with minimal trub in the fermenter (about a little less than 0.25 gallon based on my mark). Not bad for free roaming hops

So thats my current process based on my modifications. Really enjoyable brew day. Hope this helps anyone wanting to do some modifications to the system/setup.

Cheers!

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)