Discussion around here occasionally and my own experiences say don't bother. For homebrewing methods it just doesn't make a difference.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

ANVIL FOUNDRY ALL-GRAIN BREWING SYSTEM

- Thread starter czmkid

- Start date

Help Support Homebrew Talk:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

Noob_Brewer

Well-Known Member

I tend to agree with @tracer bullet. Not really sure if it matters too much for the all in one systems. BUT, for the extra 10 minutes out of my life, I still do it too lol. My rationale is that is supposedly decreases the viscosity of the wort making for a better later and sparge. Thats the rationale I use. I really am not sure about the "locking in the wort profile" benefit considering the time from mash to boil really isn't that large. So, if you do full volume mashes with no sparge and you just lift the basket and boil, I really don't see the benefit. But if sparging, like I do regularly, there MAY be a benefit. Its one of those variables that I hadn't cared to explore myself though.Does anybody do a mashout with their Foundry? My first system was a PicoBrew C, and they included that step with all of their kits. You effectively just pushed go and watched it do its thing, but I was curious enough to try and figure out what it was doing and why.

This is a step that I think I've done on a couple of my brews w/the Foundry, for no other reason than I thought maybe it needed to be done? But if not....then..one less step.

The chances of a mashout making any significant difference, either way, in the 5-10 gal batch is almost zero. How much thinner is a mash at 168 to one at 153? I don't know the answer, but my guess is not much. If you have 100+ lbs of grain to lauter/sparge it may make a difference, but with a dunk sparge or a 1-2 gals poured over, don't waist your time with a MO rest. JMHO.

Viscosity reduction from 150°F to 170°F is about 20%. Diluting the wort with sparge water gives a much larger reduction in viscosity. If doing full volume (no-sparge) mash/lauters, the viscosity starts lower because the concentration of sugar in the wort is lower.The chances of a mashout making any significant difference, either way, in the 5-10 gal batch is almost zero. How much thinner is a mash at 168 to one at 153? I don't know the answer, but my guess is not much. If you have 100+ lbs of grain to lauter/sparge it may make a difference, but with a dunk sparge or a 1-2 gals poured over, don't waist your time with a MO rest. JMHO.

Brew on

Doug, I looked at the link, and I can't make much sense out of it, but it sure doesn't look like it is a 20% reduction in viscosity between 150 f (65.6c) and 170 f (76.7c) on the graph at any of the concentrations listed. I guess a mash out may liberate a gravity point or two and it it works for those who do it great. I'm just not going to sweat it. I lift my basket and set it to boil, if I sparge I'll dunk the basket in hot/warm water or pour some through the grain and call it a day. Brew onViscosity reduction from 150°F to 170°F is about 20%. Diluting the wort with sparge water gives a much larger reduction in viscosity. If doing full volume (no-sparge) mash/lauters, the viscosity starts lower because the concentration of sugar in the wort is lower.

Brew on

Looking at the data for 20% sugar (SG =1.083) the viscosity at 150°F is 0.731, and at 170°F is 0.613 (units don't matter when looking at % change), so the percentage reduction in viscosity is:Doug, I looked at the link, and I can't make much sense out of it, but it sure doesn't look like it is a 20% reduction in viscosity between 150 f (65.6c) and 170 f (76.7c) on the graph at any of the concentrations listed. I guess a mash out may liberate a gravity point or two and it it works for those who do it great. I'm just not going to sweat it. I lift my basket and set it to boil, if I sparge I'll dunk the basket in hot/warm water or pour some through the grain and call it a day. Brew on

% Reduction = 100% * (0.613 - 0.731) / 0.731 = -16%

So, a bit less than 20%. The point of my previous post was that the viscosity reduction wasn't all that large.Brew on

$20.94

$29.99

The Brew Your Own Big Book of Clone Recipes: Featuring 300 Homebrew Recipes from Your Favorite Breweries

Amazon.com

$10.99 ($31.16 / Ounce)

Hornindal Kveik Yeast for Homebrewing - Mead, Cider, Wine, Beer - 10g Packet - Saccharomyces Cerevisiae - Sold by Shadowhive.com

Shadowhive

$719.00

$799.00

EdgeStar KC2000TWIN Full Size Dual Tap Kegerator & Draft Beer Dispenser - Black

Amazon.com

$7.79 ($7.79 / Count)

Craft A Brew - LalBrew Voss™ - Kveik Ale Yeast - For Craft Lagers - Ingredients for Home Brewing - Beer Making Supplies - (1 Pack)

Craft a Brew

$58.16

HUIZHUGS Brewing Equipment Keg Ball Lock Faucet 30cm Reinforced Silicone Hose Secondary Fermentation Homebrew Kegging Brewing Equipment

xiangshuizhenzhanglingfengshop

$479.00

$559.00

EdgeStar KC1000SS Craft Brew Kegerator for 1/6 Barrel and Cornelius Kegs

Amazon.com

$53.24

1pc Hose Barb/MFL 1.5" Tri Clamp to Ball Lock Post Liquid Gas Homebrew Kegging Fermentation Parts Brewer Hardware SUS304(Liquid Hose Barb)

yunchengshiyanhuqucuichendianzishangwuyouxiangongsi

$53.24

1pc Hose Barb/MFL 1.5" Tri Clamp to Ball Lock Post Liquid Gas Homebrew Kegging Fermentation Parts Brewer Hardware SUS304(Liquid Hose Barb)

Guangshui Weilu You Trading Co., Ltd

$33.99 ($17.00 / Count)

$41.99 ($21.00 / Count)

2 Pack 1 Gallon Large Fermentation Jars with 3 Airlocks and 2 SCREW Lids(100% Airtight Heavy Duty Lid w Silicone) - Wide Mouth Glass Jars w Scale Mark - Pickle Jars for Sauerkraut, Sourdough Starter

Qianfenie Direct

$176.97

1pc Commercial Keg Manifold 2" Tri Clamp,Ball Lock Tapping Head,Pressure Gauge/Adjustable PRV for Kegging,Fermentation Control

hanhanbaihuoxiaoshoudian

$22.00 ($623.23 / Ounce)

AMZLMPKNTW Ball Lock Sample Faucet 30cm Reinforced Silicone Hose Secondary Fermentation Homebrew Kegging joyful

无为中南商贸有限公司

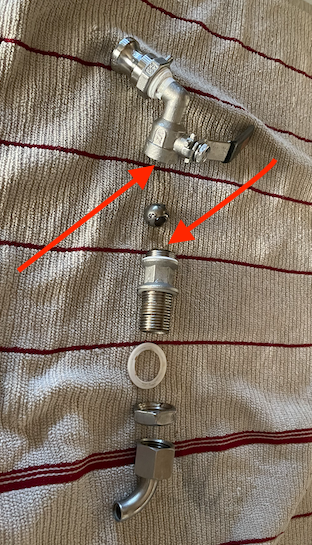

Has anybody had to replace the white nylon washers that surround the ball in the ball valve?

I looked on Anvil’s site and didn’t see it listed as a replacement part. Wondering if it standard enough that Home Depot would have it, or if a trip to a specialty store like Ace Hardware or Tru Value is needed?

I looked on Anvil’s site and didn’t see it listed as a replacement part. Wondering if it standard enough that Home Depot would have it, or if a trip to a specialty store like Ace Hardware or Tru Value is needed?

Interesting question. Are they normal, or sort of cup shaped for the ball itself? Hopefully it's a somewhat generic part, if so online might be an option. McMaster Carr?

Any issues with yours or gathering backups just in case?

Any issues with yours or gathering backups just in case?

Does anybody do a mashout with their Foundry? My first system was a PicoBrew C, and they included that step with all of their kits. You effectively just pushed go and watched it do its thing, but I was curious enough to try and figure out what it was doing and why.

This is a step that I think I've done on a couple of my brews w/the Foundry, for no other reason than I thought maybe it needed to be done? But if not....then..one less step.

I do a mash out, but usually only for 5 minutes as I don't think it really adds much unless you are sparging which I am not. I just look at it as well I need to get to boil from mash temps, so need to pass 168-172 anyway, so no harm. Then I pull the basket and while it drains I will let the wort continue heating towards a boil.

Last edited:

- Joined

- Jan 17, 2017

- Messages

- 309

- Reaction score

- 139

Hey MBG - who was the winner? Salivating beer lovers would like to knowl

If you have a recipe that was better than original please share...if you already have, my apologies. I’ll fire up the Foundry and try the clone

Cheers

KBW.

@KBW PilotHouse - Sorry for the delayed response but my son and I did the taste test this past weekend. Five of us tasted the three beers and mine won! The real Zombi Dust had a harsh bite at the beginning whereas mine and my sons were very smooth. Mine just seemed to have a bit more hop taste to it.

I dry hopped in my AllRounder in a muslin bag and I seemed to not give it enough space to expand the pellet hops so I put them in a nylon hop bag and put it in the keg for a couple more days. This probably gave mine the better hop taste.

My sons beer was quite a bit clearer then mine and the real ZD. What was strange my sons beer was a darker than the other two. He and I used the same grains. It was fun doing this again with him.

What was strange my sons beer was a darker than the other two.

More efficient / boiled longer kind of a thing? Guessing not after finding the earlier post.

Oxidation?

Interesting question. Are they normal, or sort of cup shaped for the ball itself? Hopefully it's a somewhat generic part, if so online might be an option. McMaster Carr?

Any issues with yours or gathering backups just in case?

They're cupped and sit inside the upper piece and nestled into the top of the below piece.

Problems no..but I do need to replace at least one of them.

I think I brewed a couple of times before I decided to take it apart and see....yuck.

So now I take it after every brew day. But I must have cranked down on the lower one a little bit too hard or something at some point because it sits kinda off kilter when peering down the cavity. This presumably reduces flow a little bit.

Last edited:

I just sent an email to anvil support w/a similar question. I'll report back on their response.

Timing couldn't possibly be better w/this vid. The Foundry valve is on that is mentioned.

Noob_Brewer

Well-Known Member

@Knightshade Im just curious as to what your process was early on when you started using this system for clean up? Reason why I ask is that Ive brewed on the foundry 47 times now and have taken apart the ball valve 5-6 times (can't remember) and while there is a little bit of gunk, its really not too bad at all. However, I do run a PBW CIP routine after every brew at 130 degrees for one hour with the ball valve at 3 different open positions for about 20 minutes each. All in all, I haven't seen the need to replace any of the parts of the bag valve yet as they always get squeaky clean.

@Knightshade Im just curious as to what your process was early on when you started using this system for clean up? Reason why I ask is that Ive brewed on the foundry 47 times now and have taken apart the ball valve 5-6 times (can't remember) and while there is a little bit of gunk, its really not too bad at all. However, I do run a PBW CIP routine after every brew at 130 degrees for one hour with the ball valve at 3 different open positions for about 20 minutes each. All in all, I haven't seen the need to replace any of the parts of the bag valve yet as they always get squeaky clean.

You’ve been better than me then. Outside of my last 2 brew days, I’ve never run a cleaning cycle outside of my first setup of the equipment. It involved a lot of scrubbing, rinsing, dumping, repeating. Some portion in there would involve letting water run through the valve.

For some reason…I thought that was easier less work, with less water waste. I could not have been more possibly wrong. Evidence in that my back hasn’t been SCREAMING

I did need to take it apart after my last one though…because, well..basically I’m an idiot. First recipe(kit) that used whole hops and I thought the system could handle it w/o a hop spider. Long story short.

*Ball valve was clogged.

*I tried to transfer with the only racking cane I had available which was designed for 1.5G batches…

*Which stopped really being useful after about 2G

*Then had to dump from Foundry into keg (fermenter) via a REALLY small (but biggest food safe one I had) funnel.

At least it wasn’t boring though…

Noob_Brewer

Well-Known Member

lol TBH Im not that systematic with the three ball valve positions when PBW CIPing. I usually am running the CIP around dinner time so I have time for family stuff while it runs so no big deal for me. My CIP strategy also helps making the anvil pump squeaky clean as well so good bonus. I haven't ever used a hop spider but also haven't ever used whole cone hops either so my valve hasn't ever gotten clogged. Glad you had some excitement in your recent brew day though! lolYou’ve been better than me then. Outside of my last 2 brew days, I’ve never run a cleaning cycle outside of my first setup of the equipment. It involved a lot of scrubbing, rinsing, dumping, repeating. Some portion in there would involve letting water run through the valve.

For some reason…I thought that was easier less work, with less water waste. I could not have been more possibly wrong. Evidence in that my back hasn’t been SCREAMINGat me after these last two brew sessions.

I did need to take it apart after my last one though…because, well..basically I’m an idiot. First recipe(kit) that used whole hops and I thought the system could handle it w/o a hop spider. Long story short.

*Ball valve was clogged.

*I tried to transfer with the only racking cane I had available which was designed for 1.5G batches…

*Which stopped really being useful after about 2G

*Then had to dump from Foundry into keg (fermenter) via a REALLY small (but biggest food safe one I had) funnel.

At least it wasn’t boring though…

The purpose of a mash out is to make it easier to sparge. If you do their no sparge method and pull your basket then you probably don’t need to do a mash out.I do a mash out, but usually only for 5 minutes as I don't think it really adds much unless you are sparging which I am not. I just look at it as well I need to get to boil from mash temps, so need to pass 168-172 anyway, so no harm. Then I pull the basket and while it drains I will let the wort continue heating towards a boil.

I found that pulling the basket really clouds my wort though and defeats the purpose of doing an hour mash with a recirculating pump to get clear wort. Not to mention having to deal with that stupid basket rest thing that flies out at the slightest touch. So I do not pull my mash basket now. I drain from my Foundry into my brewpot for boil on my stove top and I sparge. So I do a mash out. 170 for 10 min.

user 298779

Well-Known Member

- Joined

- Aug 1, 2021

- Messages

- 232

- Reaction score

- 147

They're cupped and sit inside the upper piece and nestled into the top of the below piece.

View attachment 746374

Problems no..but I do need to replace at least one of them.

I think I brewed a couple of times before I decided to take it apart and see....yuck.

So now I take it after every brew day. But I must have cranked down on the lower one a little bit too hard or something at some point because it sits kinda off kilter when peering down the cavity. This presumably reduces flow a little bit.

Just from my experience, Anvil probably has these available but probably not on website. If you call them I suspect they’ll send you sever replacements, and perhaps at no cost. They did that for me with adapters for Anvil thermometers.

Cheers

user 298779

Well-Known Member

- Joined

- Aug 1, 2021

- Messages

- 232

- Reaction score

- 147

Thanks for sharing this! And congrats on winning! I’ll be doing a Z-Dust clone this spring to kick off summer 2022 on Memorial Day. I’ll follow your recipe@KBW PilotHouse - Sorry for the delayed response but my son and I did the taste test this past weekend. Five of us tasted the three beers and mine won! The real Zombi Dust had a harsh bite at the beginning whereas mine and my sons were very smooth. Mine just seemed to have a bit more hop taste to it.

I dry hopped in my AllRounder in a muslin bag and I seemed to not give it enough space to expand the pellet hops so I put them in a nylon hop bag and put it in the keg for a couple more days. This probably gave mine the better hop taste.

My sons beer was quite a bit clearer then mine and the real ZD. What was strange my sons beer was a darker than the other two. He and I used the same grains. It was fun doing this again with him.

View attachment 746364

Cheers

KBW.

Just from my experience, Anvil probably has these available but probably not on website. If you call them I suspect they’ll send you sever replacements, and perhaps at no cost. They did that for me with adapters for Anvil thermometers.

Cheers

They’re just going to ship me a new valve today. As you suspected, they do have the part but…..that damn supply chain.

I’m paraphrasing a bit, but they’re out and can only get them when they order foundries or bucket fermenters and due to shipping delays…

This is twice now where their customer service has completely blown me out of the water.

The purpose of a mash out is to make it easier to sparge. If you do their no sparge method and pull your basket then you probably don’t need to do a mash out.

I found that pulling the basket really clouds my wort though and defeats the purpose of doing an hour mash with a recirculating pump to get clear wort. Not to mention having to deal with that stupid basket rest thing that flies out at the slightest touch. So I do not pull my mash basket now. I drain from my Foundry into my brewpot for boil on my stove top and I sparge. So I do a mash out. 170 for 10 min.

Sure pulling the basket will cloud the wort because it's splashing, but doesn't it clear up after the boil when it settles after chilling? I whirlpool during chilling and once at temp will pull chiller, let it whirlpool for 10 more minutes, then shut off whirlpool and let it sit for 15-20 minutes and wort is pretty clear. Below is my Helles brewed this past Saturday after doing these steps and pulling a sample. Will say I do use whirlfloc and Brew Tan B which combine to drop all the suspended protein, so when I say clear wort, I really mean clear.

- Joined

- Dec 5, 2007

- Messages

- 1,719

- Reaction score

- 759

Is the reason you don't boil in the Foundry only because you don't want to pull the mash basket?The purpose of a mash out is to make it easier to sparge. If you do their no sparge method and pull your basket then you probably don’t need to do a mash out.

I found that pulling the basket really clouds my wort though and defeats the purpose of doing an hour mash with a recirculating pump to get clear wort. Not to mention having to deal with that stupid basket rest thing that flies out at the slightest touch. So I do not pull my mash basket now. I drain from my Foundry into my brewpot for boil on my stove top and I sparge. So I do a mash out. 170 for 10 min.

So how long do you think before Anvil does something similar for the Foundry? I know that some of your are pushing the absolute limits of this thing already. Might be handy for somebody who bought the 6.5, who finds themselves wanting to brew bigger batches and doesn't want to buy a 10.5 too?

So how long do you think before Anvil does something similar for the Foundry? I know that some of your are pushing the absolute limits of this thing already. Might be handy for somebody who bought the 6.5, who finds themselves wanting to brew bigger batches and doesn't want to buy a 10.5 too?

What fun you'll have when one of those clips fails (or you fail to secure one properly.)

Brew on

What fun you'll have when one of those clips fails (or you fail to secure one properly.)

Brew on

Right, serious kind of precarious.

user 298779

Well-Known Member

- Joined

- Aug 1, 2021

- Messages

- 232

- Reaction score

- 147

It’s a nice idea in theory, but hoping Anvil doesn’t go that route. I agree with Doug - those clips seem sketchy. If the extension were to leak during boil it’d be a legit safety concern.What fun you'll have when one of those clips fails (or you fail to secure one properly.)

Brew on

It‘s possible they’d never leak but is it worth the risk? I’m in the camp with selling the smaller foundry, saving for the additional cost and buy a larger one. I have a Foundry 6.5 and would never try to extend the height. Just MHO though.

Cheers

Summa_Brewologica

Well-Known Member

- Joined

- Nov 11, 2020

- Messages

- 228

- Reaction score

- 98

Anyone have a hop spider recommendation? One that can be moved to the center of a wort chiller when the time comes? I’m also considering wilser hop bags.

edit: this for the 10.5 gallon foundry

edit: this for the 10.5 gallon foundry

Noob_Brewer

Well-Known Member

sorry I personally don't have a recommendation on this. Ive always just let my hops roam free and take a little bit more losses into the fermenter after letting the hops and trub settle. I have a wilder hop bag which I got along with my wilser bag for mashing but never used the hop bag.Anyone have a hop spider recommendation? One that can be moved to the center of a wort chiller when the time comes? I’m also considering wilser hop bags.

edit: this for the 10.5 gallon foundry

Does anybody do a mashout with their Foundry? My first system was a PicoBrew C, and they included that step with all of their kits. You effectively just pushed go and watched it do its thing, but I was curious enough to try and figure out what it was doing and why.

This is a step that I think I've done on a couple of my brews w/the Foundry, for no other reason than I thought maybe it needed to be done? But if not....then..one less step.

Basically I will just heat from mash temps to 170, but then pull the basket immediately at that temp and will continue ramping up to 200 while the basket drains, then one I remove the basket, bump it up to boil.

Similar threads

- Replies

- 12

- Views

- 898

- Replies

- 14

- Views

- 1K

- Replies

- 27

- Views

- 3K

- Replies

- 4

- Views

- 1K

Latest posts

-

-

-

-

-

-

Spike Conical Heater fails again--second in 3 years--ideas?

- Latest: Indian_villager

![Craft A Brew - Safale BE-256 Yeast - Fermentis - Belgian Ale Dry Yeast - For Belgian & Strong Ales - Ingredients for Home Brewing - Beer Making Supplies - [3 Pack]](https://m.media-amazon.com/images/I/51bcKEwQmWL._SL500_.jpg)