Completed my second brew on this on sunday...after work, which was awesome.

Each brew has taken roughly 4 hours with cleanup. First batch was a NEIPA 12.5lbs overall 70% efficiency. Second brew was a kolsch with 9.25lbs 72% efficiency. I know I can increase those numbers as I was hitting OG but was over on total volume.

Overall super happy with this unit, excited to up it to 240v, I'm still on 120v and have no complaints.

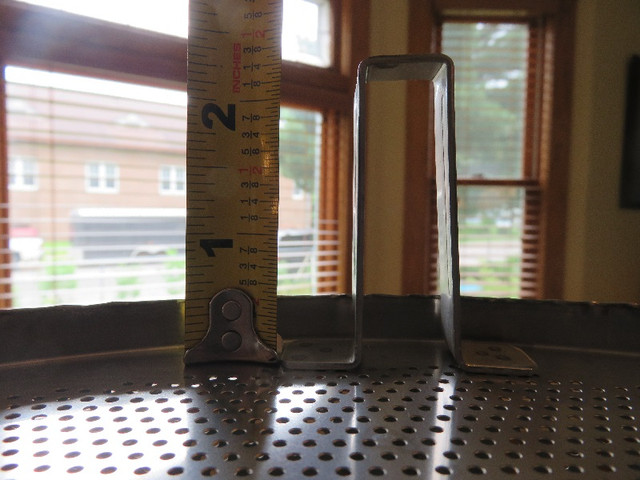

One note the gap on the bulkhead can be a bit if a problem, after cleaning up after the first batch the alignment of the double wall came loose and I didn't notice until I added my strike water for the next brew and it started leaking like crazy out the seams all around the unit. Easy fix though just had to empty, realign, and tighten the bulkhead worked like a charm after that.

View attachment 631764

![Craft A Brew - Safale BE-256 Yeast - Fermentis - Belgian Ale Dry Yeast - For Belgian & Strong Ales - Ingredients for Home Brewing - Beer Making Supplies - [3 Pack]](https://m.media-amazon.com/images/I/51bcKEwQmWL._SL500_.jpg)