Well, a little bit of an update...

First off, the chamber is painted and up and running, though still no temp controller. One thing has been updated though, above and beyond the paint job - I've got a PC case fan installed and running, sitting right on the freezer coils. As a result, I've got the fridge currently set to 2.5 out of 7 - and the beer pictured above is crash cooling in there and down to 38F after about 48 hours. Not too shabby.

So, I mentioned earlier I'd be building a temperature controller - specifically, the one from

this thread.

I'm waiting for the controller itself to show up, but I've gotten all the other bits and pieces together and started putting it together, so hopefully most of the work will be done when the box turns up:

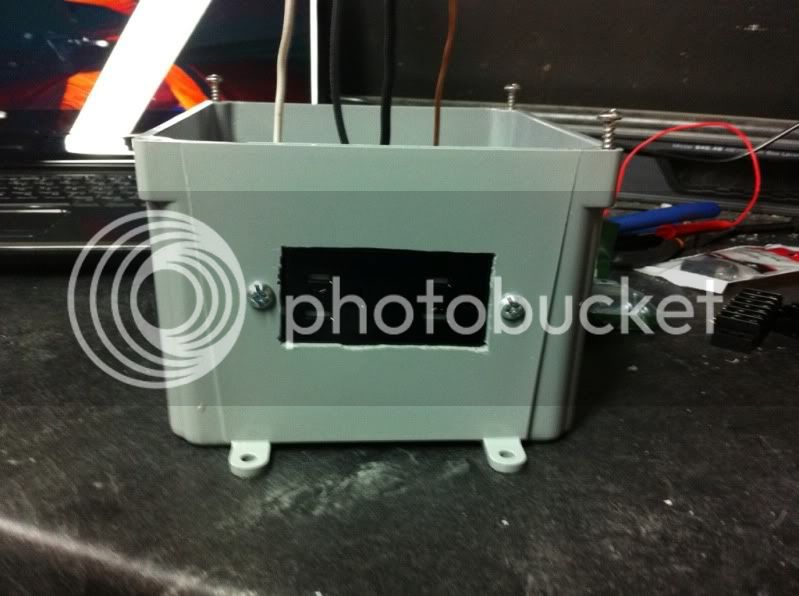

I'm using a few ideas liberally borrowed from the thread I linked to, many in the last 5-10 pages of that thread. I'm using a 6x6x4 outdoor plastic junction box from Home Depot (I'm told this is overkill and that 4x4x4 is doable - but I wanted as much room as I could get so I could see what I'm doing). In addition to the basics from the very first post in that thread, I'm stealing a couple ideas from KrazyDave... One, that should be pretty dang easy, probably pretty dang unnecessary, but I think pretty cool, is a pair of LED lamps to indicate when the heat or cool side of the controller is running. The other idea, and the one that intimidates me a bit, is that rather than directly and permanently connecting the temperature probe to the controller, I'm going to permanently attach a 1/8" mono headphone jack to the controller, and a 1/8" mono headphone plug to the probe. I'm doing this for a few reasons:

1) I'm clumsy, and it's only a matter of time before I snag something on that wire - no matter how carefully concealed - and cause damage. The 1/8" plug should make for a semi-effective break away connection to protect from just that eventuality.

2) It'll force me to do a little minor soldering of electrical components - something I've never done before and want to learn how to do. Hopefully this doesn't go horribly wrong. Even if it does, I have 2 plugs and 2 jacks, so I have 2 tries at either option before I have to re-purchase anything.

3) It just looks cool.

Anyway, here's my current progress - not a whole hell of a lot is done so far: